Melt-blown non-woven material with electret effect and preparation method of melt-blown non-woven material

An electret and melt-blown technology, which is applied in the direction of melt spinning, textiles, papermaking, non-woven fabrics, etc., can solve problems such as the fluidity difference between electret masterbatch and melt-blown resin, so as to improve product quality, increase output, The effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

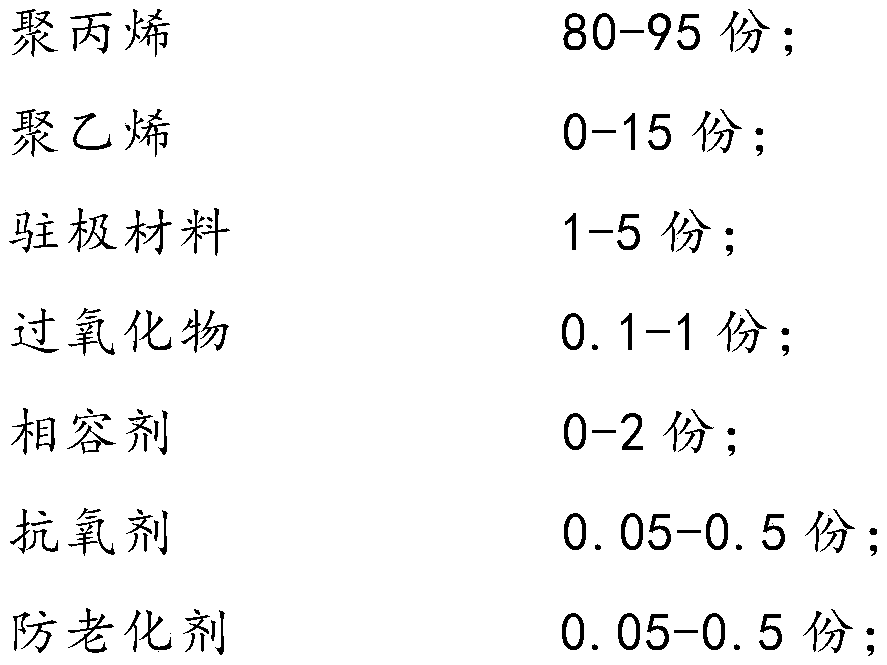

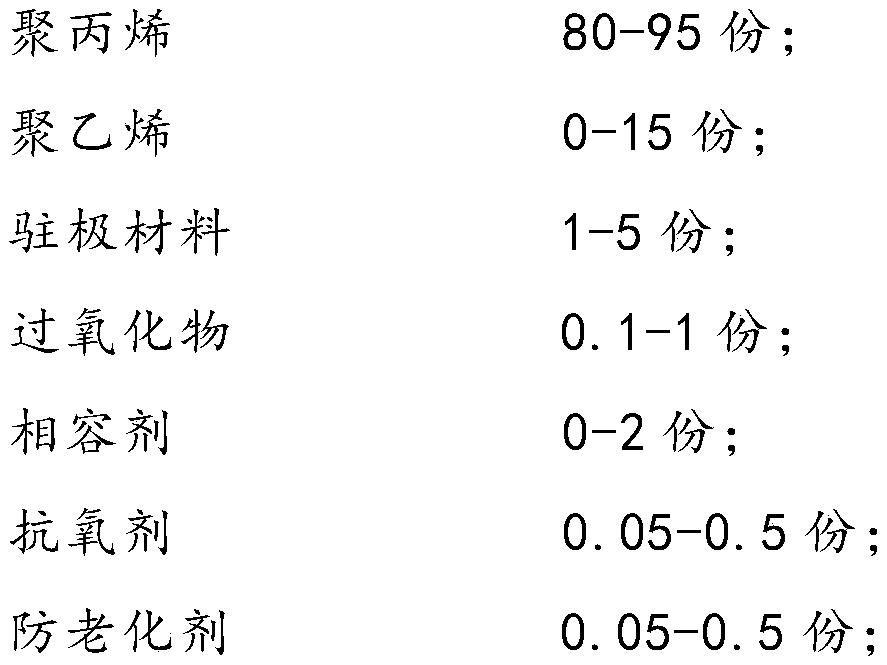

[0031] Step 1: Prepare raw materials according to the components and parts by weight in Table 1;

[0032] Step 2: Mix the homopolypropylene, zinc stearate and fumed silica prepared in step 1 evenly with a high-speed machine to obtain the first compound, and add the first compound from the end of the screw extruder , melt extruded to form a melt, after the di-tert-butyl peroxide, maleic anhydride grafted polypropylene, antioxidant and anti-aging agent prepared in step 1 were mixed uniformly with a high-speed machine, the second compound was obtained , the second compound is added from the front end of the screw extruder, and mixed with the melt obtained after the first compound is melted and extruded to obtain a blended melt; the temperature of the melting section of the screw extruder is 160-220 ° C, And the screw extruder is provided with a twin-screw with an aspect ratio of 50;

[0033] Step 3: Cool and granulate the blended melt in Step 2.

Embodiment 2

[0035] Step 1: Prepare raw materials according to the components and parts by weight in Table 1;

[0036] Step 2: Mix the homopolypropylene, zinc stearate and calcium carbonate prepared in step 1 evenly with a high-speed machine to obtain the first compound, add the first compound from the end of the screw extruder, melt Extrude to form a melt, after the di-tert-butyl peroxide prepared in step 1, maleic anhydride grafted polypropylene, antioxidant and antiaging agent are mixed uniformly with a high-speed machine, the second compound is obtained, and The second compound is added from the front end of the screw extruder, and mixed with the melt obtained after the first compound is melted and extruded to obtain a blended melt; the temperature of the melting section of the screw extruder is 160-220 ° C, and the screw extruder The extruder is equipped with a twin-screw with an aspect ratio of 50;

[0037] Step 3: Cool and granulate the blended melt in Step 2.

Embodiment 3

[0039] Step 1: Prepare raw materials according to the components and parts by weight in Table 1;

[0040] Step 2: After homogeneously mixing the homopolypropylene, polyethylene, zinc stearate and fumed silica prepared in step 1 with a high-speed machine, the first compound is obtained, and the first compound is fed from the screw extruder Add at the end of the compound, melt and extrude to form a melt, and mix the di-tert-butyl peroxide, maleic anhydride grafted polypropylene, antioxidant and anti-aging agent prepared in step 1 with a high-speed machine to obtain the second The second compound, the second compound is added from the front end of the screw extruder, mixed with the melt obtained after the first compound is melted and extruded, to obtain a blended melt; the temperature of the melting section of the screw extruder is 160- 220°C, and the screw extruder is equipped with twin-screws with an aspect ratio of 50;

[0041] Step 3: Cool and granulate the blended melt in S...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com