Water-based rust conversion anticorrosive coating for steel structures, and preparation method thereof

An anti-corrosion coating, rust conversion technology, applied in anti-corrosion coatings, coatings, conjugated diene coatings, etc., can solve the problems of no weather resistance, unstable system, low hardness of the paint film, etc. Corrosion resistance, improve elastic shielding effect, hinder the effect of electron transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0053] Described first component water-based epoxy-vinylidene chloride-acrylic acid emulsion, its preparation method comprises the following steps:

[0054] (1) In parts by weight, take 100 parts of epoxy resins in a three-necked flask with an electronic balance, add 7 parts of catalysts, and add 2 parts of polymerization inhibitors and 60 parts of acrylic acid monomers to heat up to Stir and react at 200°C until the theoretical point of acid value is reached, and 50 parts of epoxy-modified acrylic acid intermediates are obtained;

[0055] (2) Add 100 parts of emulsifier and 200 parts of deionized water into the three-necked flask, completely dissolve the emulsifier under the stirring of the rotor, and then add 50 parts of vinylidene chloride monomer and 50 parts of the intermediate obtained in step (1) for stirring and form a pre-emulsion;

[0056] (3) Add 3 parts of initiator into the pressure reaction kettle, pass nitrogen gas for a period of time to exhaust the air in the...

Embodiment 1

[0081] The formulation of a novel water-based rust conversion anticorrosion coating is shown in Table 1.

[0082] Table 1:

[0083]

[0084] The preparation method of coating of the present invention is as follows

[0085] 1. Preparation of component A:

[0086] (1) Add the water-based epoxy-vinylidene chloride-acrylic acid emulsion into the dispersion tank according to the formula amount, and then add the cosolvent ethylene glycol butyl ether, defoamer BYK-028, and water-based rust conversion agent ferrous according to the formula amount Potassium cyanide was dispersed at high speed (800-1000r / min) for 15 minutes to obtain mixture I;

[0087] (2) Under stirring at low speed (300-500r / min), add the raw material of water-based polyaniline elastic nano-modified particles into the mixture I, and disperse at high speed (900-1100r / min) for 10 minutes. After the dispersion is complete, add Organic bentonite and deionized water, after adjusting the viscosity to obtain component...

Embodiment 2

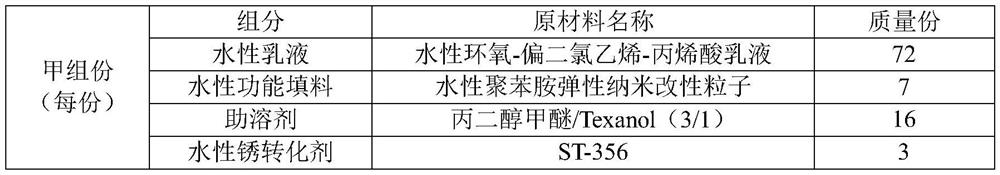

[0093] The formulation of a novel water-based rust conversion anticorrosion coating is shown in Table 2.

[0094] Table 2

[0095]

[0096] The preparation method of coating of the present invention is as follows

[0097] 1. Preparation of component A:

[0098] (1) Add the water-based epoxy-vinylidene chloride-acrylic acid emulsion into the dispersion tank according to the formula amount, and then add the co-solvent dipropylene glycol methyl ether, defoamer BYK-014, and water-based rust conversion agent RC980 according to the formula amount. (800-1000r / min) dispersed for 15 minutes to obtain mixture I;

[0099](2) Under stirring at low speed (300-500r / min), add the raw material of water-based polyaniline elastic nano-modified particles into the mixture I, and disperse at high speed (900-1100r / min) for 10 minutes. After the dispersion is complete, add Xanthan gum and deionized water, after adjusting the viscosity to get component A, just pack according to the proportion; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com