Oil-proof high-and low-temperature resistant cable

A technology of high and low temperature resistance and high temperature resistance, used in the field of high and low temperature oil resistant cables, can solve the problems of high temperature resistance and oil resistance not meeting the requirements, achieve excellent high and low temperature resistance, increase high temperature resistance and mechanical strength, and increase compatibility. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

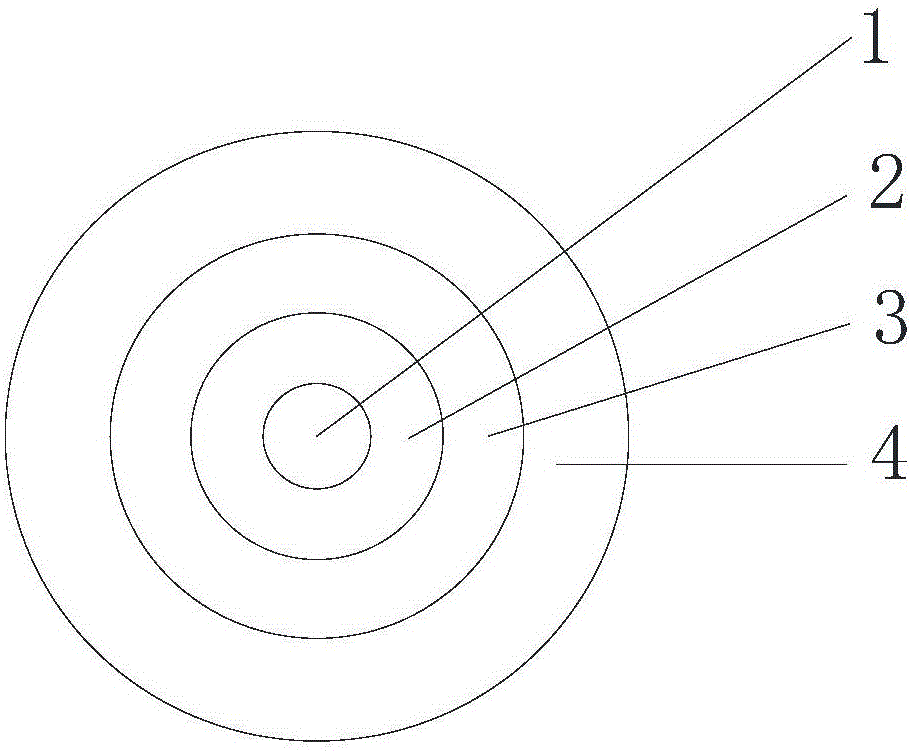

[0022] A high-temperature and low-temperature oil-resistant cable, comprising a wire, a high-temperature-resistant insulating layer covering the wire, a shielding layer covering the high-temperature-resistant insulating layer, and a protective layer covering the shielding layer;

[0023] Among them, the raw materials of the protective layer include by weight: 60 parts of EPDM rubber, 40 parts of silicone rubber, 15 parts of modified sepiolite, 25 parts of modified white carbon black, 1 part of ferric oxide, three parts of citric acid 25 parts of butyl ester, 20 parts of epoxidized soybean oil, 20 parts of microencapsulated red phosphorus, 10 parts of nano-magnesium hydroxide, 2.5 parts of Si69, 1 part of sulfur, 1 part of dicumyl peroxide, triene isocyanurate 0.5 parts of propyl ester, 0.5 parts of stearic acid, 0.2 parts of zinc oxide, 3 parts of dibutyltin oxide, 1 part of rare earth stabilizer, 2640.3 parts of anti-aging agent, 40100.2 parts of anti-aging agent, 5 parts of p...

Embodiment 2

[0028] A high-temperature and low-temperature oil-resistant cable, comprising a wire, a high-temperature-resistant insulating layer covering the wire, a shielding layer covering the high-temperature-resistant insulating layer, and a protective layer covering the shielding layer;

[0029] Among them, the raw materials of the protective layer include by weight: 80 parts of EPDM rubber, 20 parts of silicone rubber, 25 parts of modified sepiolite, 15 parts of modified white carbon black, 3 parts of ferric oxide, three parts of citric acid 15 parts of butyl ester, 30 parts of epoxidized soybean oil, 10 parts of microencapsulated red phosphorus, 30 parts of nano-magnesium hydroxide, 0.5 parts of Si69, 2 parts of sulfur, 0.5 parts of dicumyl peroxide, triene isocyanurate 0.8 parts of propyl ester, 0.2 parts of stearic acid, 0.4 parts of zinc oxide, 2 parts of dibutyltin oxide, 2 parts of rare earth stabilizer, 2640.1 parts of anti-aging agent, 40100.4 parts of anti-aging agent, 3 parts ...

Embodiment 3

[0034] A high-temperature and low-temperature oil-resistant cable, comprising a wire, a high-temperature-resistant insulating layer covering the wire, a shielding layer covering the high-temperature-resistant insulating layer, and a protective layer covering the shielding layer;

[0035] Among them, the raw materials of the protective layer include by weight: 65 parts of EPDM rubber, 35 parts of silicone rubber, 18 parts of modified sepiolite, 22 parts of modified white carbon black, 1.5 parts of ferric oxide, three parts of citric acid 23 parts of butyl ester, 23 parts of epoxidized soybean oil, 17 parts of microencapsulated red phosphorus, 15 parts of nano-magnesium hydroxide, 2 parts of Si692, 1.2 parts of sulfur, 0.9 parts of dicumyl peroxide, triallyl isocyanurate 0.6 parts, 0.4 parts of stearic acid, 0.25 parts of zinc oxide, 2.7 parts of dibutyltin oxide, 1.2 parts of rare earth stabilizer, 2640.25 parts of anti-aging agent, 0.25 parts of anti-aging agent, 4.5 parts of p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com