Preparation method of catalyst organotin acetate in sucralose production

A technology of sucralose and organotin, which is applied to the preparation of sugar derivatives, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of solvent volatilization, high energy consumption, and long preparation time, and achieve improved production efficiency , The process is simple and the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

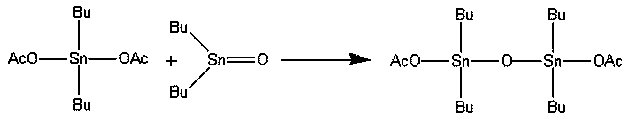

Method used

Image

Examples

Embodiment 1

[0028] 1. Add 100g of dibutyltin diacetate liquid into a 500ml three-necked flask, start stirring, raise the temperature to 80°C, slowly add 70g of dibutyltin oxide into the three-necked flask, and finish adding in about 30 minutes.

[0029] 2. After the addition of dibutyltin oxide, raise the temperature to 100°C and start to heat and dissolve for 3 hours. After the dissolution is complete, heat for half an hour and cool down to 80°C.

[0030] 3. Distill the reacted liquid under reduced pressure at -0.95MPa and 80°C until no components are distilled out, and the reaction is over. 176.8 g of organotin acetate can be obtained. It is solid at room temperature and liquid above 60°C.

[0031] 4. Finally, the prepared organotin acetate (DSDA) is used as a catalyst, and returns to the esterification section to participate in the esterification reaction for reuse.

Embodiment 2

[0033] 1. Add 100g of dibutyltin diacetate liquid into a 500ml three-necked flask, start stirring, raise the temperature to 60°C, slowly add 82g of dibutyltin oxide into the three-necked flask, and finish adding in about 2 hours.

[0034] 2. After adding dibutyltin oxide, raise the temperature to 70°C and start to keep warm and dissolve for 4 hours. After the dissolution is complete, keep warm for half an hour, and then cool down to 60°C.

[0035] 3. Distill the reacted liquid under reduced pressure at -0.95MPa, 60°C until no components are distilled out, and the reaction is over. 177.1 g of organotin acetate can be obtained. It is solid at room temperature and liquid above 60°C.

[0036] 4. Finally, the prepared organotin acetate (DSDA) is used as a catalyst, and returns to the esterification section to participate in the esterification reaction for reuse.

Embodiment 3

[0038] 1. Add 100g of dibutyltin diacetate liquid into a 500ml three-necked flask, start stirring, raise the temperature to 100°C, slowly add 70g of dibutyltin oxide into the three-necked flask, and finish adding in about 60 minutes.

[0039] 2. After adding dibutyltin oxide, heat it at 100°C for 2 hours to dissolve. After the dissolution is complete, heat it for half an hour and cool down to 80°C.

[0040] 3. Distill the reacted liquid under reduced pressure at -0.95MPa, 80°C until no components are distilled out, and the reaction is over. 176.9 g of organotin acetate can be obtained. It is solid at room temperature and liquid above 60°C.

[0041] 4. Finally, the prepared organotin acetate (DSDA) is used as a catalyst, and returns to the esterification section to participate in the esterification reaction for reuse.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com