Sealing method of gas making furnace discharging ash round door and device

A technology for gas-making furnaces and round doors, which is applied in the field of gas-making furnaces, can solve problems such as poor sealing of the round doors of gas-making furnaces, and achieve the effects of reducing maintenance workload, reducing steam and coal consumption, and saving usage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

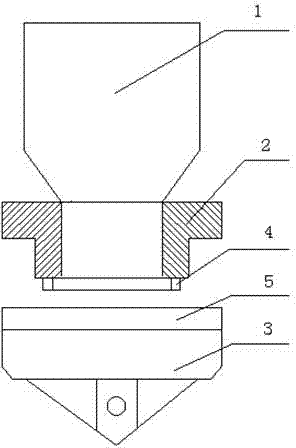

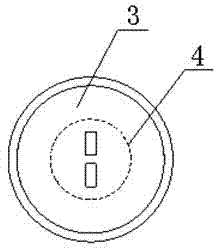

[0011] Embodiment of the present invention: a kind of sealing method and device of the ash round door under the gas-generating furnace of the present invention can be implemented on the basis of the existing ash round door under the gas-generating furnace, such as figure 1 and figure 2 As shown, during implementation, a sealing seat 2 is welded at the port at the bottom of the existing ash hopper 1, the sealing seat is preferably made of stainless steel, and a raised stainless steel sealing ring is made on the end face of the sealing seat at the same time 4. At the same time, fix a rubber plate 5 that can completely cover the stainless steel sealing ring 4 on the existing lower gray round door 3. In this way, when the lower ash round door 3 is covered on the sealing seat 2 by the traditional threaded connection method or the buckle fastening method, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com