Technique for smelting stainless steel through RKEF (rotary kiln-electric furnace) and AOD furnace duplex process

A kind of stainless steel and process technology, which is applied in the field of smelting stainless steel to achieve the effect of shortening the time of production, reducing power consumption and increasing production capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

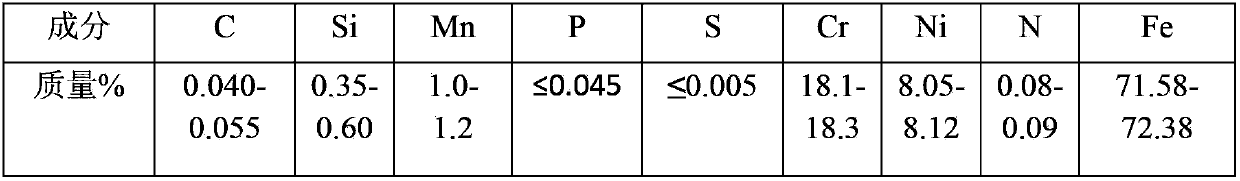

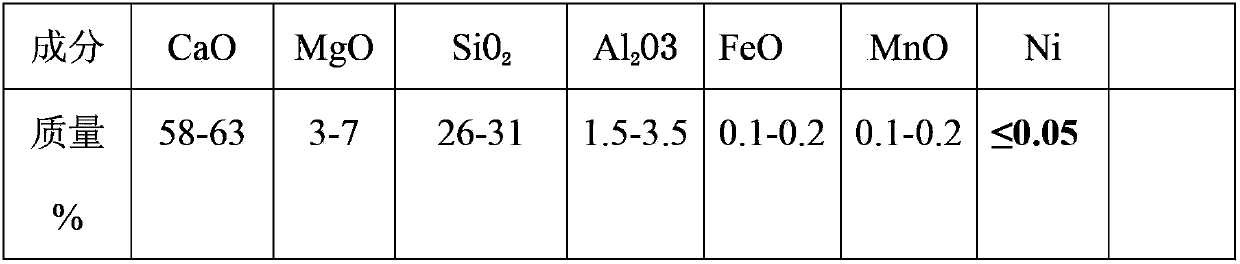

[0039] Now take the production of stainless steel as an example on 33000kVA electric furnace, 45tAOD refining furnace, LF refining furnace, R10 two-machine two-flow small slab continuous casting machine, describe and implement the method of the present invention:

[0040] 1) According to the temperature of the crude nickel alloy molten iron required for the AOD refining furnace to enter the furnace, the crude nickel alloy is smelted by the RKEF process, and the Si / Mg (mass ratio) is controlled between 1.75-1.85 by controlling the slag type;

[0041] 2) Strictly control the slag temperature and iron temperature during the production of coarse nickel alloy, the slag temperature is controlled within the range of 1550-1570°C; the iron temperature is controlled within the range of 1500-1520°C;

[0042] 3) Ladles are used to hold thick nickel alloy molten iron;

[0043] 4) Immediately cover the thick nickel alloy molten iron with carbonized rice husk (insulation material) to control...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com