Method for producing cylinder crankcase and cylinder crankcase

A technology for crankcases and cylinders, which is applied in the field of producing cylinders and crankcases with foreign matter enclosed, which can solve problems such as high cleaning costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

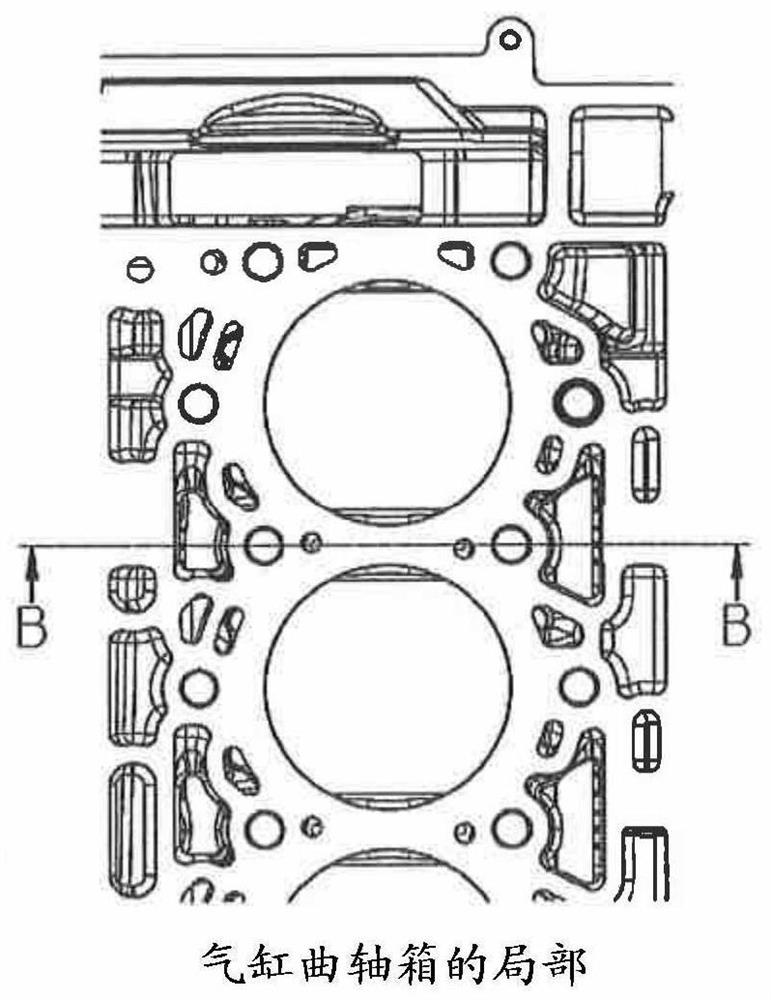

[0013] figure 1 shows a detail of a cylinder crankcase of an internal combustion engine, in particular a diesel internal combustion engine.

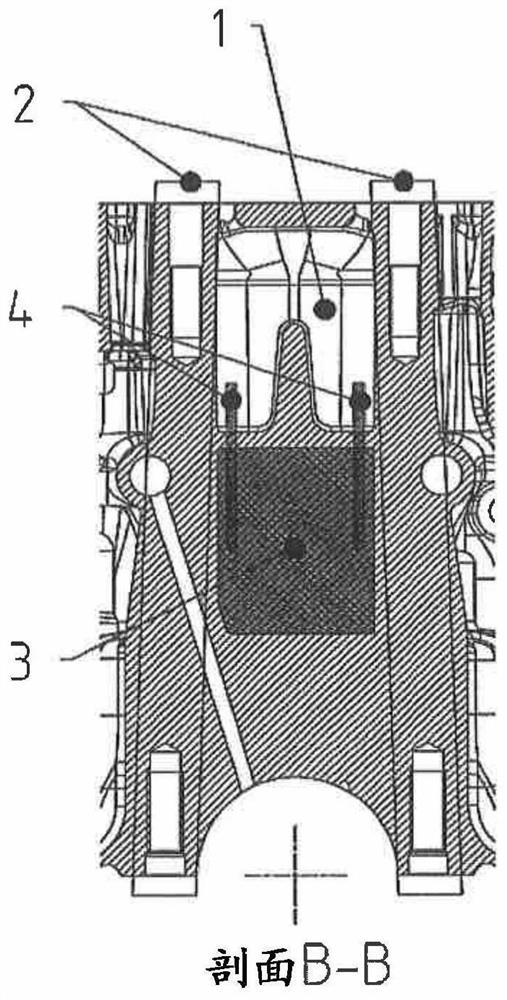

[0014] figure 2 public figure 1 A cross-sectional view of the internal combustion engine along the line B-B. The water jacket 1 between the tension anchors 2 is separated from the tension anchor core 3 by the cast material of the cylinder crankcase of the internal combustion engine. Like the tension anchor core 3 , the pin 4 driven into the tension anchor core 3 is also surrounded by the cast material of the cylinder crankcase of the internal combustion engine, so that no contamination of the core material occurs during subsequent motor operation.

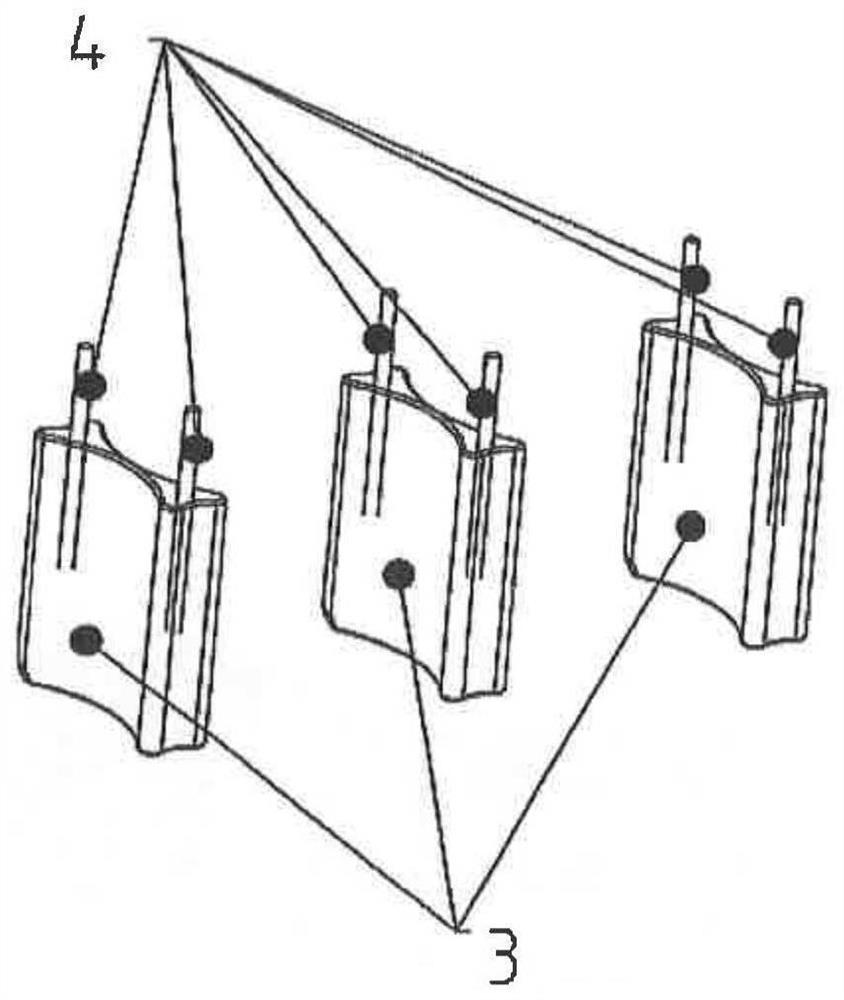

[0015] image 3 The pin 4 driven into the tension anchor core 3 is shown in .

[0016] Figure 4 Showing the water jacket core 5 and image 3 Tension anchor core 3 to be installed in .

[0017] The following solution is shown in the present invention: from figure 2 Below the middle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com