Forming die head of battery barrier film

A technology of barrier film and battery, applied in battery pack parts, circuits, electrical components, etc., can solve the problems of complex production process of barrier film, insufficient mold structure and precision, complicated process, etc. The effect of drawing process, low scrap rate and high forming precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

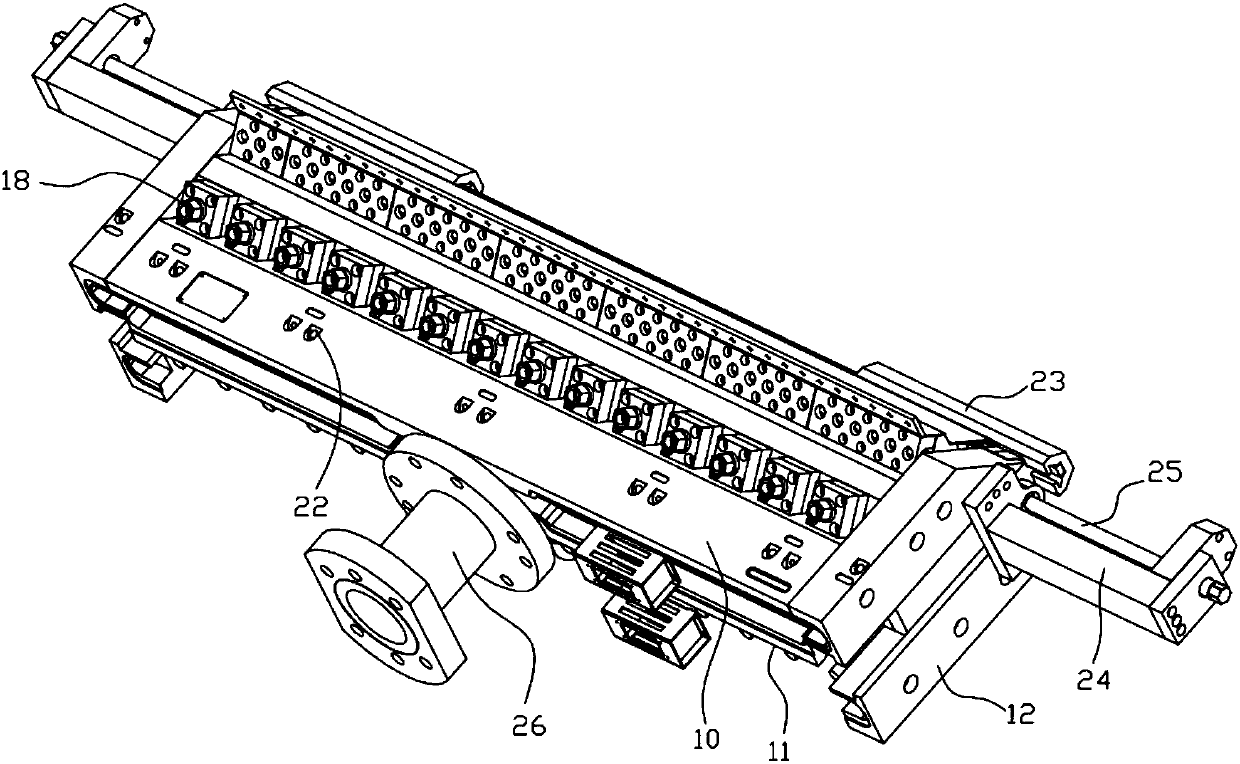

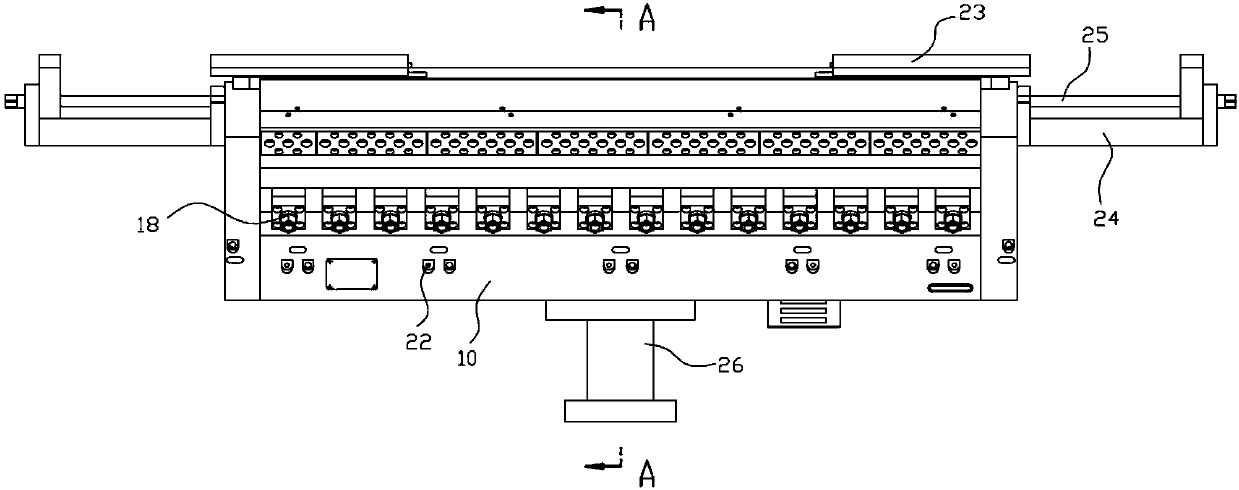

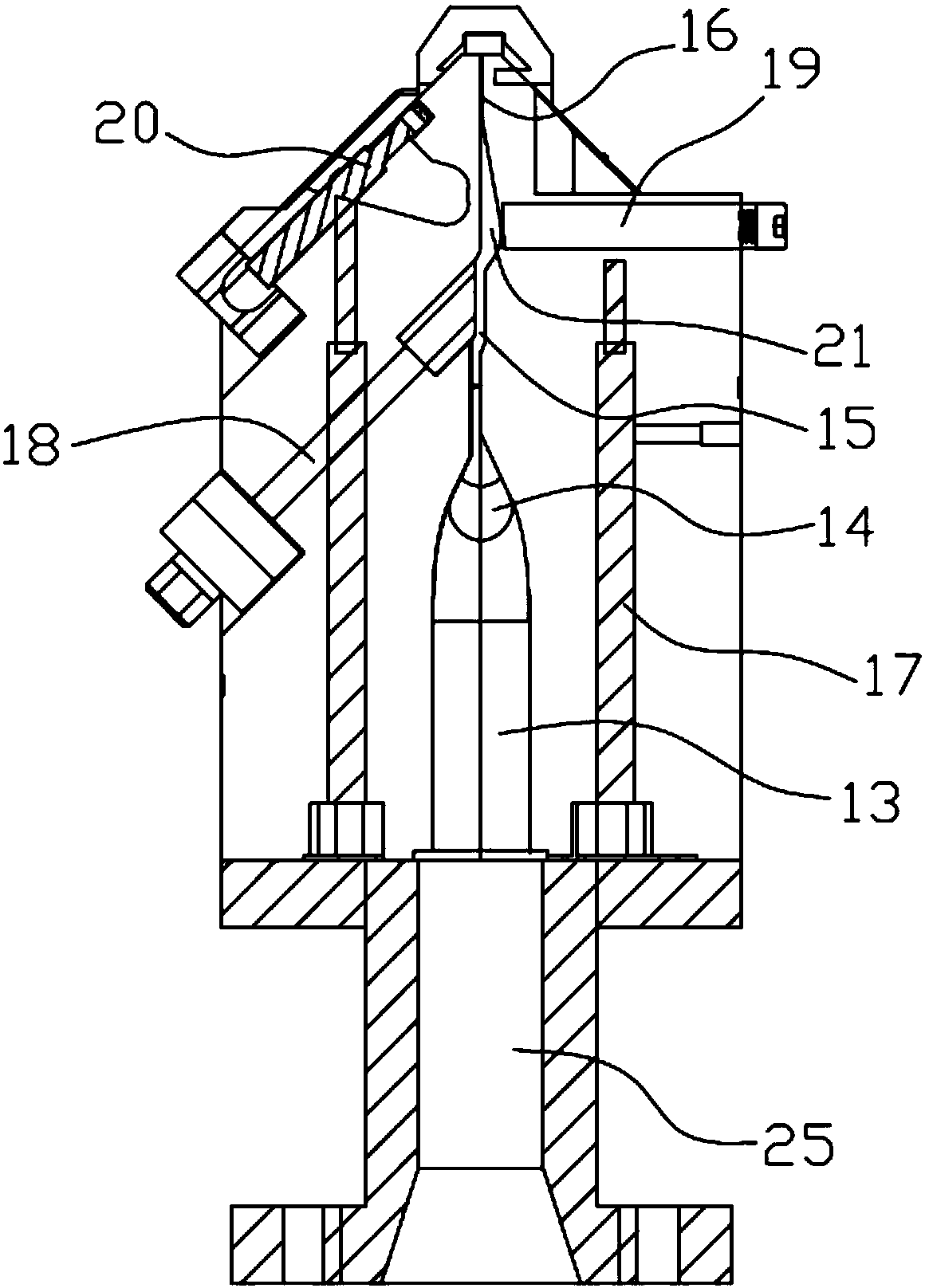

[0015] Below in conjunction with accompanying drawing, the present invention will be further described with specific embodiment, see figure 1 —4: A molding die head for a battery barrier film, including an upper mold 10 and a lower mold 11, both of which are fixed by a mold frame 12, and the upper mold 10 and the lower mold 11 are all provided with a row of heating rods 17 in the longitudinal direction, From the feed port 13 to the discharge port, wherein, the die cavity formed by the upper mold 10 and the lower die 11 is an extrusion flow channel, and the extrusion flow channel is divided into a preheating section 14 and an extrusion section 15 And the discharge section 16, the preheating section 14 is flat, located in the middle of the mold cavity, extending to both sides of the mold cavity, and communicated with the feed port 13, the two form a T shape, the space height of the preheating section 14 It is larger than the extrusion section 15 and the discharge section 16. Aft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com