Die for die casting and method of manufacturing cast product

A technology of the mold and product department, which is applied in the field of molds for die-casting and the manufacture of casting products, can solve the problems of lack of strength of the protruding part, it is difficult to fill the protruding part with molten metal, and achieve the effect of reducing casting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

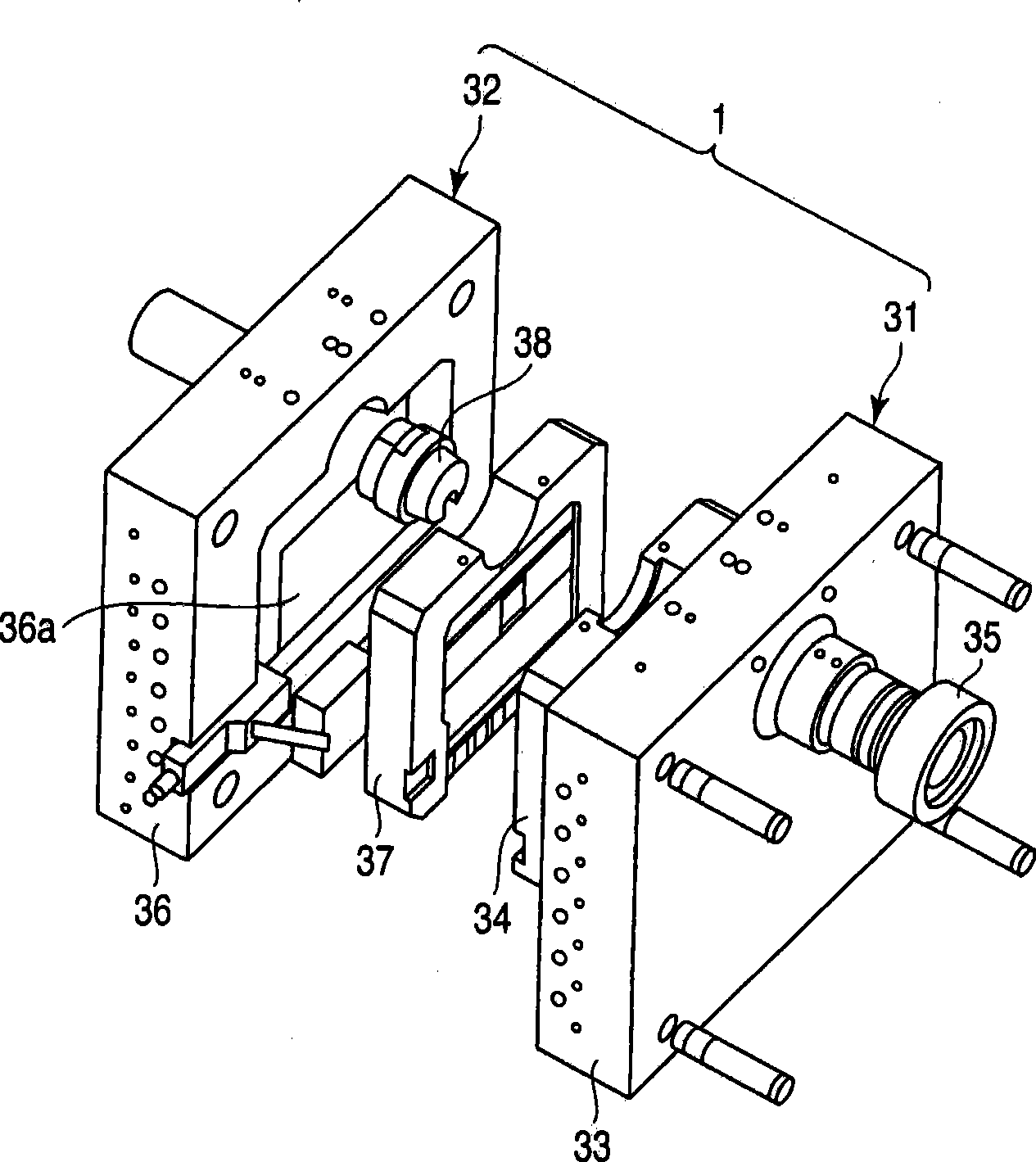

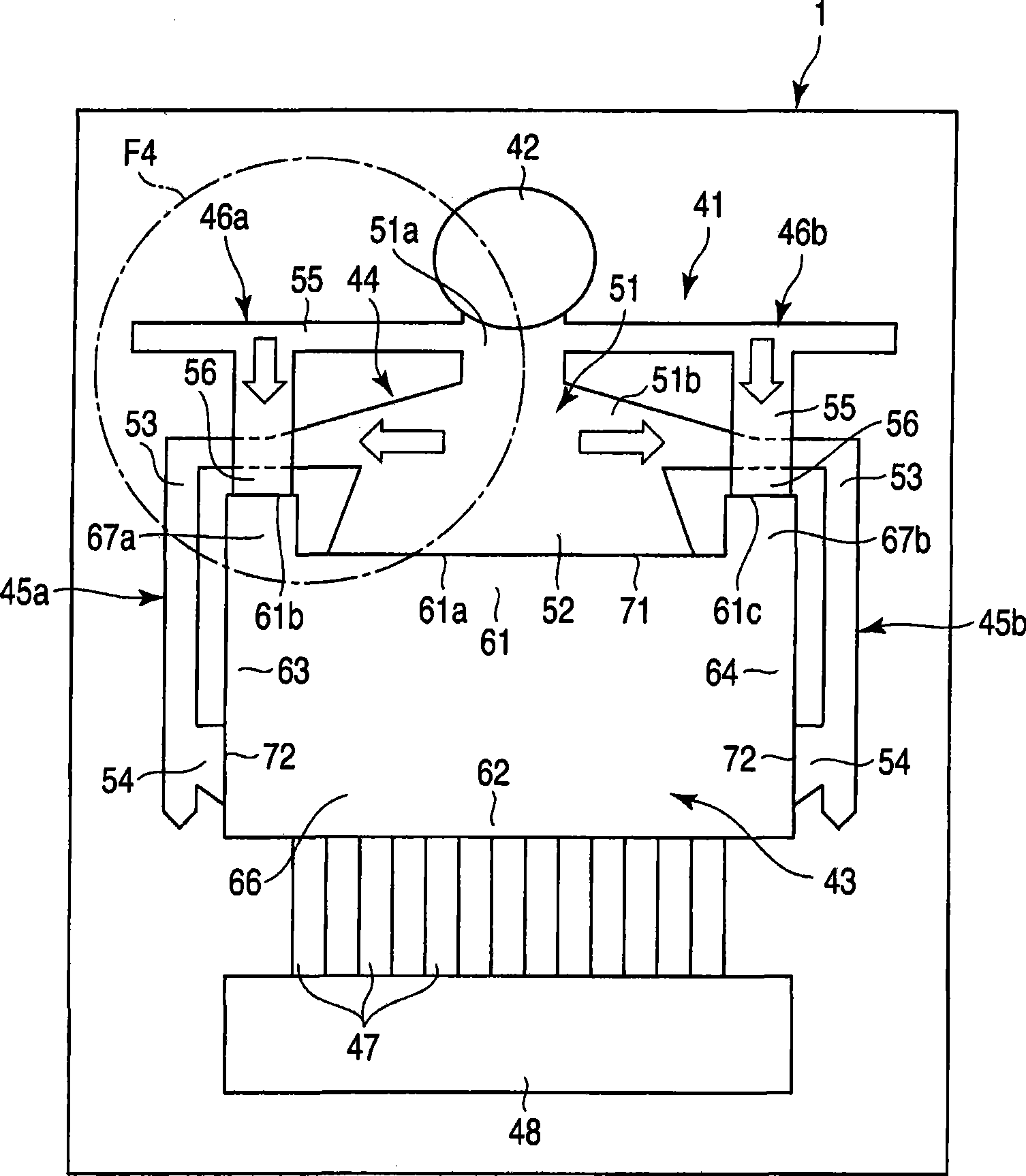

[0022] The following will refer to Figures 1 to 4 A mold 1 according to an embodiment of the present invention, and a method of producing a cast product 2 are described. figure 1 A mold 1 according to this embodiment is shown.

[0023] The mold 1 is used for die casting in a cold-chamber die casting system, for example. For example, magnesium alloy, aluminum alloy or zinc alloy is injected into this mold 1 by pressure as a molten metal. Incidentally, the die according to the present invention is not limited to the above-mentioned materials, and can be widely used for die-casting various materials used as molten metal.

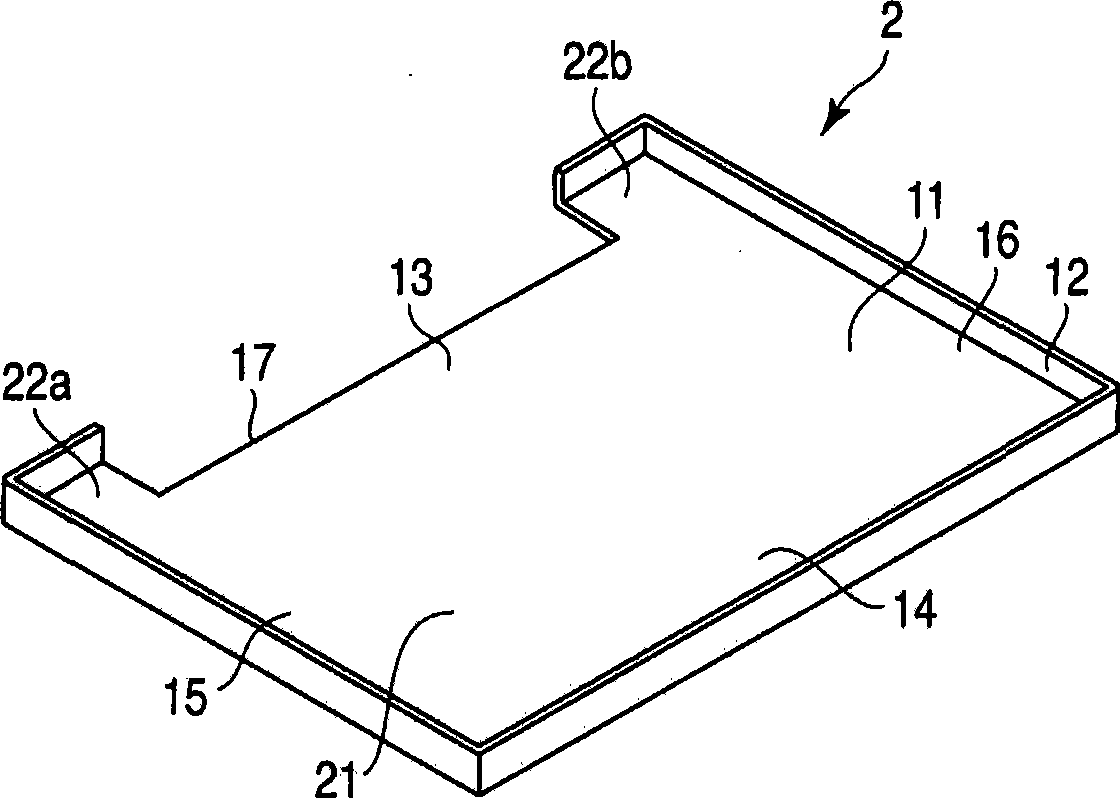

[0024] figure 2 An example of a cast product 2 of a product cast by using the mold 1 is shown. This cast product 2 is, for example, a component constituting a part of a main body casing of an electronic device such as a laptop computer, or a part of a casing of a display unit of an electronic device. A case constituting the bottom of the device main body...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com