Magnesium alloy semi-solid production method

A production method, semi-solid technology, applied in the field of cold die-casting, can solve the problem of small size, achieve the effect of improving comprehensive mechanical properties, high production efficiency, and saving time for soup making

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

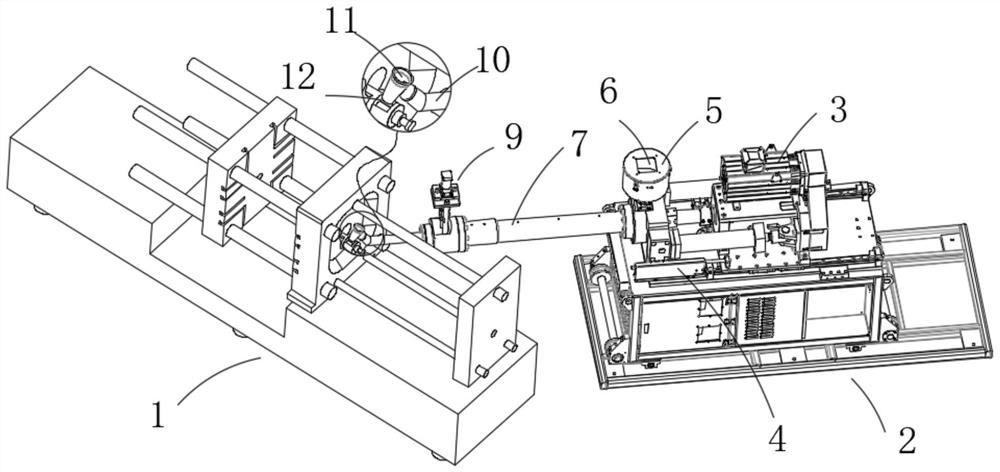

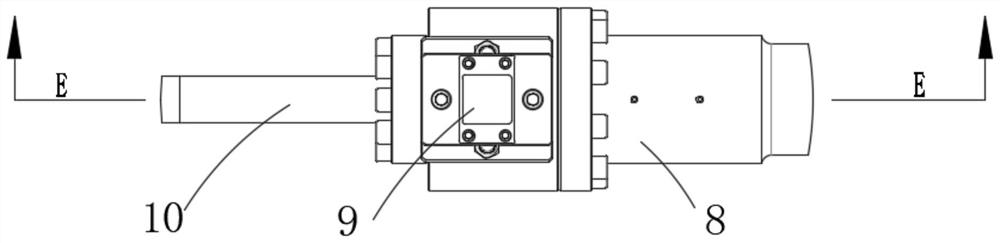

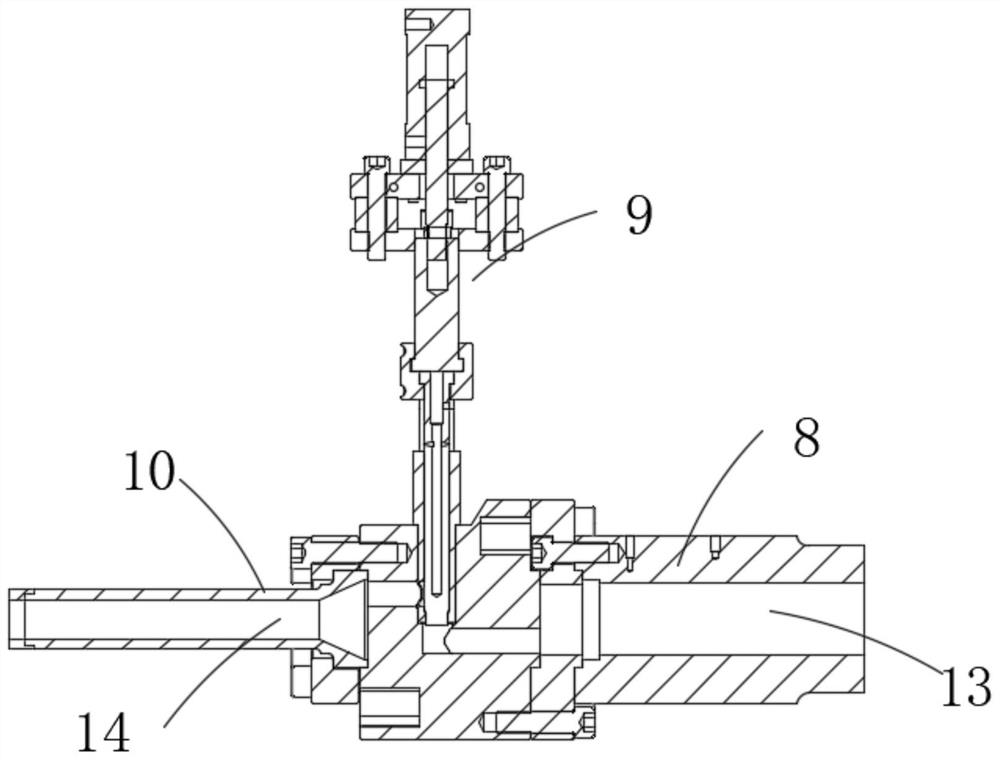

[0026] like Figure 1-4 As shown, a magnesium alloy semi-solid production method proposed by the present invention includes a production system, the production system includes an injection system 1 and a soup injection system 2, and a servo motor 3 is installed on the soup injection system 2, and the two sides of the servo motor 3 An oil cylinder 4 is provided, and the outer ring of the output end of the servo motor 3 is provided with a feed pipe 7, the output end of the servo motor 3 is connected with a screw rod, and one end of the feed pipe 7 is equipped with a feed mechanism 5, and the feed mechanism 5 is provided with The other end of the feed inlet 6 and the feed pipe 7 is connected with a connecting pipe 8, and the other end of the connecting pipe 8 is sealed with a check valve 9, and one side of the check valve 9 is provided with a discharge pipe 10, and the discharge pipe 10 The end away from the one-way valve 9 is connected with a discharge nozzle 11, and the input e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com