Concrete construction method for large-slope inclined roof

A construction method and concrete technology, applied in construction, building structure, construction material processing and other directions, can solve the problems of high formwork support requirements, difficult insertion of vibrators, and high construction cost, and achieve reduction of non-compacting and internal damage, Guarantee the molding quality and avoid the effect of rework and repair

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

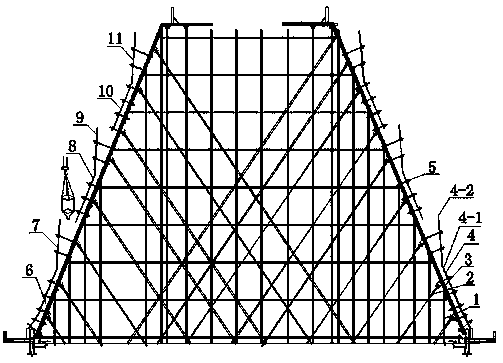

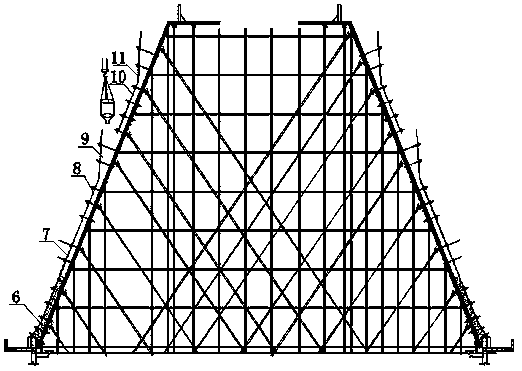

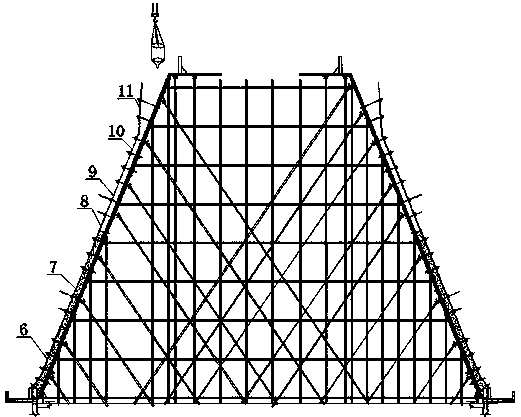

[0044] The present invention will be described in further detail below in conjunction with the accompanying drawings and examples.

[0045] This embodiment is a concrete construction method for a large-slope inclined roof, which is carried out in the following steps:

[0046] A. Construction of the bottom formwork and support frame of the sloping roof

[0047] (1) Erection of bottom formwork and scaffolding support system

[0048] Using full-hole fastener scaffolding support system ( figure 1 , Figure 6 shown), before scaffolding 1 is erected, the beam edge line, sloping roof ridge and inner corner line (horizontal projection line of the entire sloping roof) are released on the floor in advance, and the standpipe of scaffold 1 is made of Ф48X3. The vertical and horizontal spacing of the pipes is 1000-1200mm, and the specific spacing should be determined according to calculations. A vertical and horizontal tie rod is installed every 1500mm above; because the formwork suppor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Slump | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com