Method for preparing boron carbide ceramic through low-temperature pulse pressurization

A boron carbide ceramic and pulse technology, which is applied in the field of boron carbide ceramic material processing and preparation, can solve the problems of destroying the lightness and poor performance of boron carbide ceramics, and achieve the effects of industrialized mass production, reduced sintering time and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

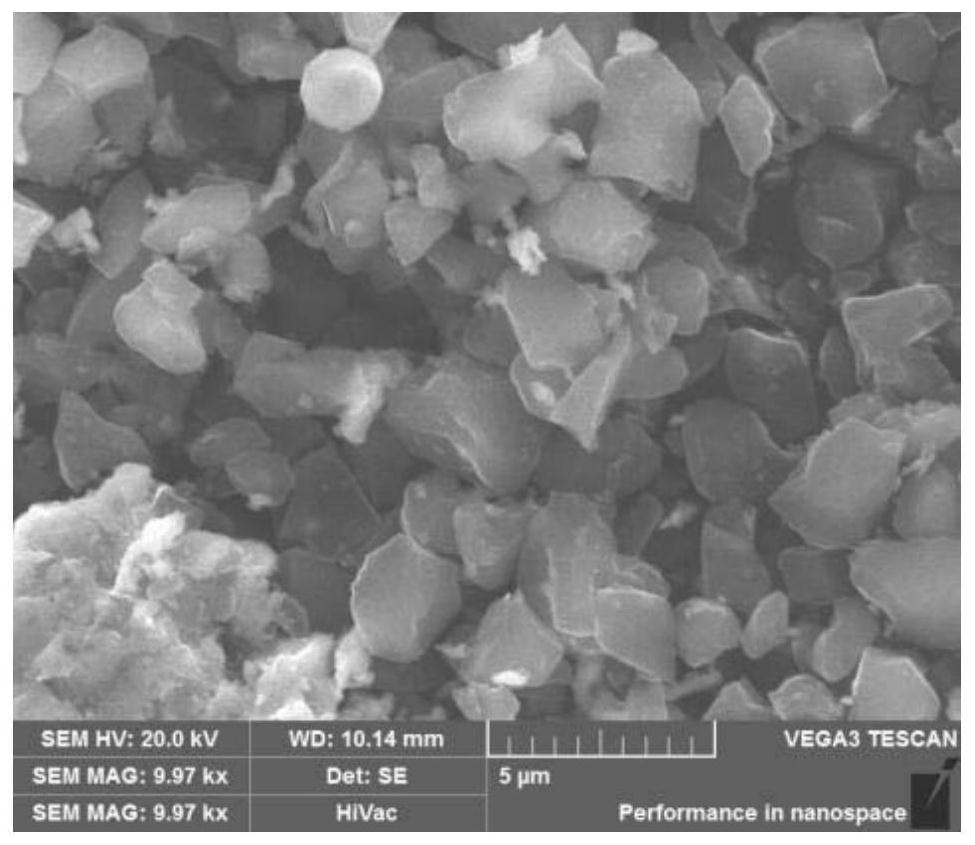

[0025] First select B with a particle size of 25 μm 4 C powder is used as raw material powder. After vacuum drying, it is poured into a drum and placed on a planetary ball mill. After drying, the powder passes through sieves of 650, 800 and 900 mesh in sequence to obtain boron carbide powder after ball milling. The boron carbide powder that this implementation prepares is as figure 2 As shown, the particle size of boron carbide is about 2um.

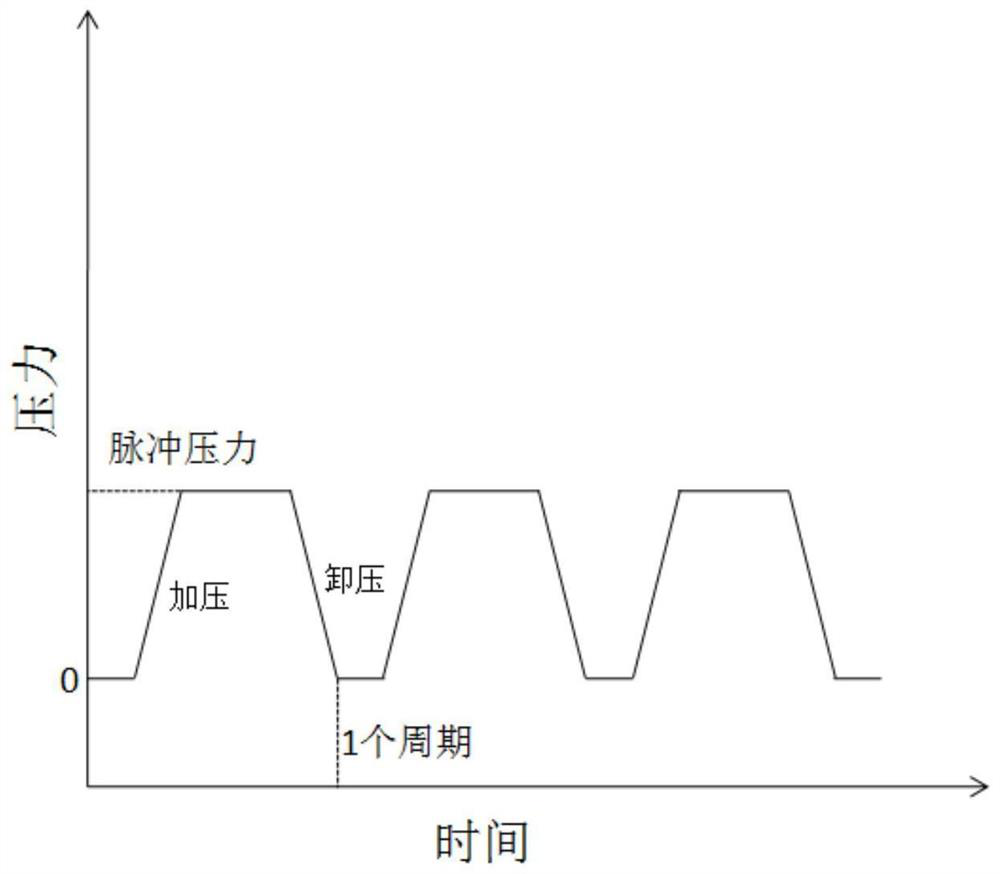

[0026] Boron carbide powder is added in the mold of pressurization device, and boron carbide powder and mold are separated by graphite paper, then pressurization device is put into the pressure sintering furnace, under vacuum atmosphere (furnace vacuum control is 900Pa ), heating with a heating rate of 10°C / min, and pulse pressurization when the temperature rises to 100°C. Through the pressurization device, control the upper and lower indenters to apply 30MPa pulse pressure to the mold, and the pressure is controlled by the pressure s...

Embodiment 2

[0028] First select B with a particle size of 25 μm 4 C powder is used as raw material powder. After vacuum drying, it is poured into a drum and placed on a planetary ball mill. After drying, the powder passes through sieves of 650, 800 and 900 mesh in sequence to obtain boron carbide powder after ball milling.

[0029] Boron carbide powder is added in the mold of pressurization device, and boron carbide powder and mold are separated by graphite paper, then pressurization device is put into the pressure sintering furnace, under vacuum atmosphere (furnace vacuum control is 900Pa ), heating with a heating rate of 8°C / min, and pulse pressurization when the temperature rises to 100°C. Through the pressurization device, control the upper and lower pressure heads to apply 35MPa pulse pressure to the mold, and the pressure sensor at the bottom of the pressure head. The size is monitored in real time. The boost rate is 5MPa / min. After boosting to 35MPa, keep it for 8 minutes, and the...

Embodiment 3

[0031] First, select B with a particle size of 30 μm 4 C powder is used as raw material powder. After vacuum drying, it is poured into a drum and placed on a planetary ball mill. After drying, the powder passes through sieves of 650, 800 and 900 mesh in sequence to obtain boron carbide powder after ball milling.

[0032]Boron carbide powder is added in the mold of pressurization device, and boron carbide powder and mold are separated by graphite paper, then pressurization device is put into the pressure sintering furnace, under vacuum atmosphere (furnace vacuum control is 900Pa ), heating with a heating rate of 15°C / min, and pulse pressurization when the temperature rises to 100°C. Through the pressurization device, the upper and lower pressure heads are controlled to apply 40MPa pulse pressure to the mold, and the pressure is controlled by the pressure sensor at the bottom of the pressure head. The size is monitored in real time. The boost rate is 10MPa / min. After boosting t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| Vickers hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com