A cement craft product made from waste material and its preparation method

A technology of waste materials and cement, applied in the field of handicrafts, can solve the problems of soil and water environmental pollution, poor appearance of products, occupying land resources, etc., and achieve the effect of increasing surface area, facilitating sintering and preparation, and avoiding stress concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

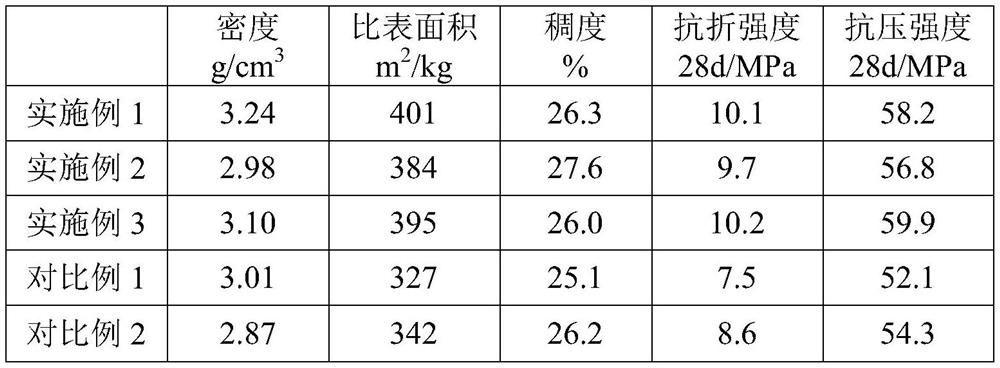

Examples

Embodiment 1

[0027] A cement craft product made from waste materials, comprising the following raw materials in parts by weight: 25 parts of furnace bottom slag, 30 parts of fly ash, 80 parts of waste glass of 100-140 mesh, 30 parts of waste ceramics of 30-40 mesh, 0.2 parts of coagulant, 0.6 parts of water reducing agent, 6 parts of mineral toner and 30 parts of raw meal scraps;

[0028] The raw meal scraps include crop straw and raw meal, and the weight ratio of the crop straw to raw meal is 1:3.

[0029] Preferably, the bottom slag includes the following raw materials in parts by weight: 20 parts of calcium oxide, 40 parts of silicon dioxide and 5 parts of aluminum oxide.

[0030] Preferably, the fly ash includes the following raw materials in parts by weight: 25 parts of silicon dioxide, 15 parts of aluminum oxide and 10 parts of ferric oxide.

[0031] A method for preparing cement craft products made from waste materials, comprising the following steps:

[0032] Step 1: Add furnace ...

Embodiment 2

[0041] A cement craft product made from waste materials, comprising the following raw materials in parts by weight: 30 parts of furnace bottom slag, 35 parts of fly ash, 80 parts of 100-140 mesh waste glass, 40 parts of 30-40 mesh waste ceramics, 0.4 parts of coagulant, 0.8 parts of water reducer, 8 parts of mineral toner and 35 parts of raw meal scraps;

[0042] The raw meal scraps include crop straw and raw meal, and the weight ratio of the crop straw and raw meal is 1:3.

[0043] Preferably, the bottom slag includes the following raw materials in parts by weight: 25 parts of calcium oxide, 45 parts of silicon dioxide and 10 parts of aluminum oxide.

[0044] Preferably, the fly ash includes the following raw materials in parts by weight: 30 parts of silicon dioxide, 20 parts of aluminum oxide and 15 parts of ferric oxide.

[0045]A method for preparing cement craft products made from waste materials, comprising the following steps:

[0046] Step 1: Add furnace bottom slag,...

Embodiment 3

[0055] A cement craft product made from waste materials, comprising the following raw materials in parts by weight: 28 parts of furnace bottom slag, 32 parts of fly ash, 100 parts of 100-140 mesh waste glass, 35 parts of 30-40 mesh waste ceramics, 0.3 parts of coagulant, 0.7 parts of water reducer, 7 parts of mineral toner and 32 parts of raw meal scraps;

[0056] The raw meal scraps include crop straw and raw meal, and the weight ratio of the crop straw to raw meal is 1:3.

[0057] Preferably, the bottom slag includes the following raw materials in parts by weight: 24 parts of calcium oxide, 43 parts of silicon dioxide and 8 parts of aluminum oxide.

[0058] Preferably, the fly ash includes the following raw materials in parts by weight: 27 parts of silicon dioxide, 18 parts of aluminum oxide and 12 parts of ferric oxide.

[0059] A method for preparing cement craft products made from waste materials, comprising the following steps:

[0060] Step 1: Add furnace bottom slag,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com