Light high-strength silicon nitride bonded silicon carbide refractory and preparation method thereof

A technology of refractory materials and silicon carbide, which is applied in the field of refractory materials, can solve the problems of low specific strength of refractory materials, increased energy consumption of material heat capacity, and reduced material life, so as to achieve the effect of increasing specific strength, low cost and reducing heat capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

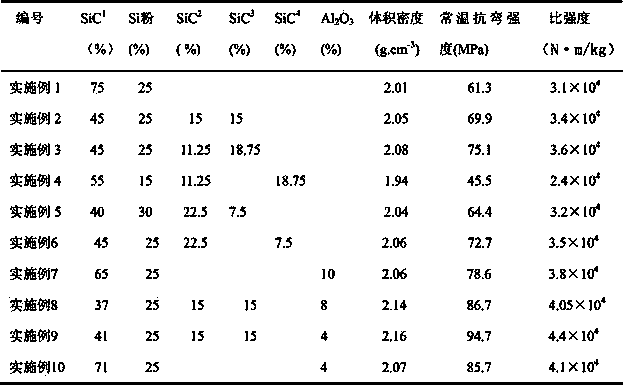

Examples

Embodiment 1、2、4、5、8、9、10

[0021] The preparation method of embodiment 1,2,4,5,8,9,10:

[0022] After mixing all the raw materials, carry out ball milling, use absolute ethanol as the ball milling medium, use Si in the planetary mill 3 N 4 Ball milling for 24 hours (the mass ratio of raw materials, balls and absolute ethanol is 1:1.5:1), the ball milling time is 10 hours, the slurry after ball milling is dried at 60°C, and PVA with 10% weight of raw materials is added to granulate , pass through a 40-mesh sieve, place at room temperature for 24 hours, take an appropriate amount of granulated powder in a mold, and dry press to form it. The forming pressure is 40-45MPa. The formed test strip is 80mm long, 7.5mm wide, and about 5.7mm high , degumming, after degumming, nitriding and sintering in a high-temperature vacuum atmosphere sintering furnace under the condition of flowing high-purity nitrogen (purity>99.99%) (nitrogen flow rate: 1-3L / min) to obtain light-weight and high-strength silicon nitride bon...

Embodiment 3、6、7

[0023] The preparation method of embodiment 3,6,7:

[0024] After mixing all the raw materials, carry out ball milling, use absolute ethanol as the ball milling medium, use Si in the planetary mill 3 N 4 Ball milling for 24 hours (the mass ratio of raw materials, balls and absolute ethanol is 1:1.5:1.5), the ball milling time is 8 hours, the slurry after ball milling is dried at 80°C, and PVA with 12% raw material weight is added to granulate , passed through a 60-mesh sieve, placed at room temperature for 24 hours, took an appropriate amount of granulated powder in the mold, and dry-pressed it to form it. The forming pressure was 50-55 MPa. The formed test strip was 80 mm long, 7.5 mm wide, and about 5.5 mm high. , degumming, after degumming, nitriding and sintering in a high-temperature vacuum atmosphere sintering furnace under the condition of flowing high-purity nitrogen (purity>99.99%) (nitrogen flow rate: 1-3L / min) to obtain light-weight and high-strength silicon nitrid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com