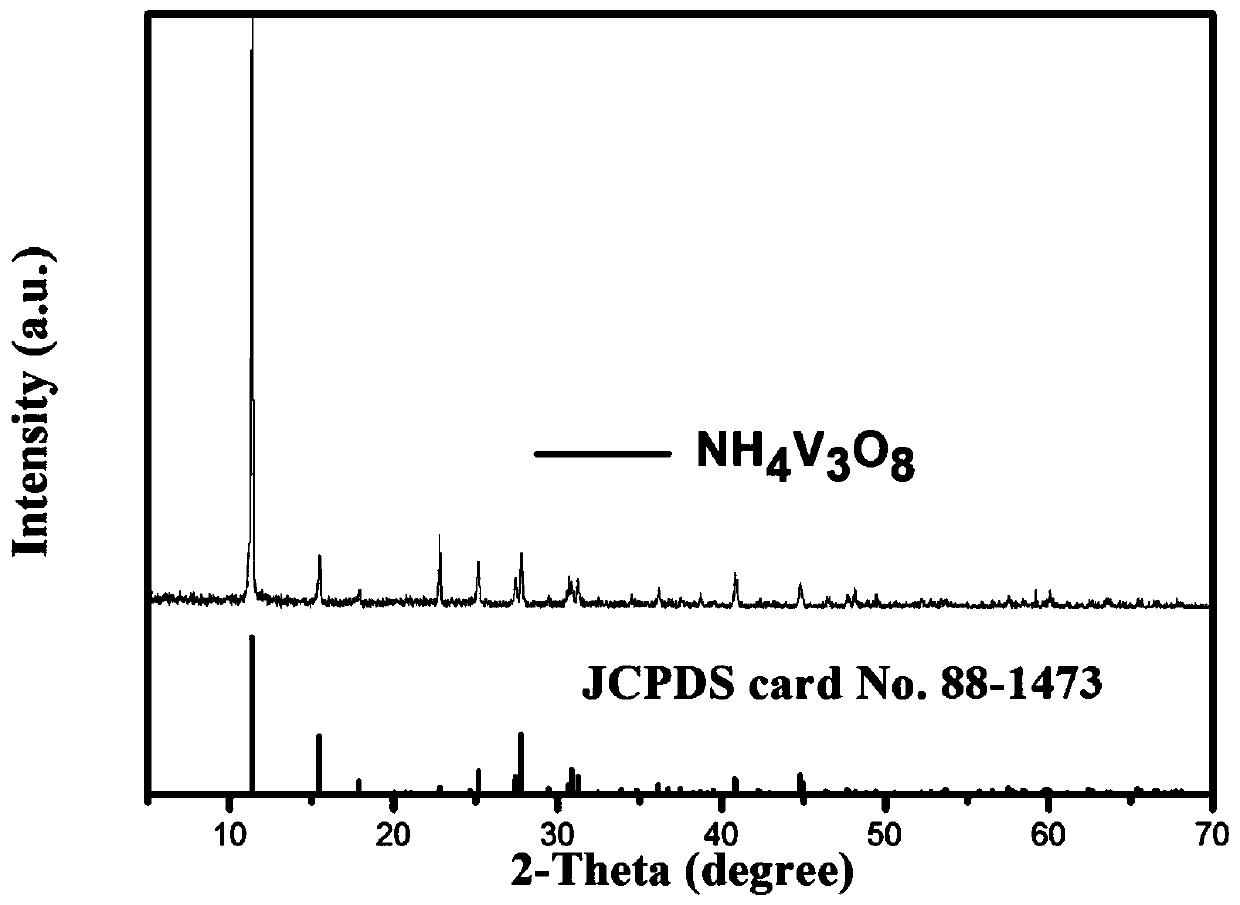

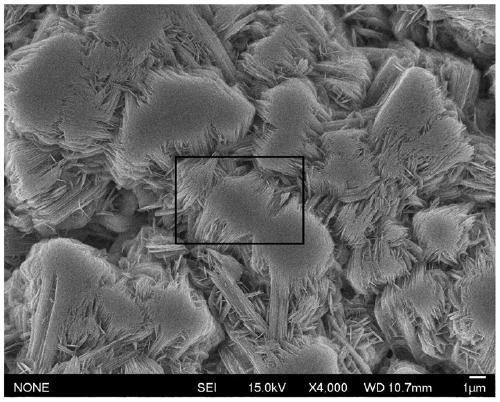

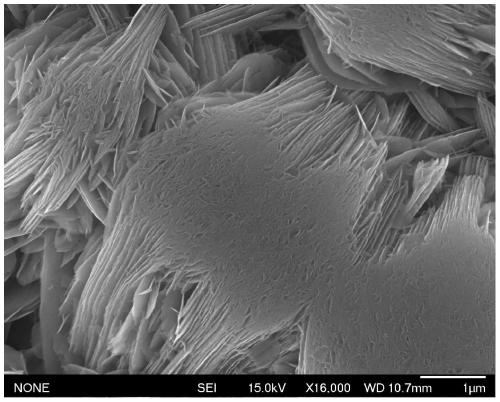

Method for preparing ultra-thin nano sheet Nh4V3O8 nano material under ultra-high pressure

A technology of nanosheets and nanomaterials, applied in nanotechnology, nanotechnology, chemical instruments and methods, etc., can solve the problems that nanosheets have not been reported, and achieve environmental protection in the preparation process, buffer volume changes, and increase effective connections. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Preparation of ultra-thin nano flake NH by ultra-high pressure 4 V 3 O 8 The nanomaterial method includes the following steps:

[0028] Step 1: Add 0.08g of 1-methyl-3-ethylimidazole chloride to 10mL of water to dissolve, then add 0.05g of ethylenediaminetetraacetic acid and stir to form a mixed solution;

[0029] Step 2: Add 5mL of 50% ethylene glycol to the mixed solution and then add 0.3g of NH 4 VO 3 And heating to make NH 4 VO 3 Fully dissolved into NH 4 VO 3 Solution; Among them, the heating temperature is 50℃;

[0030] Step 3: Put NH 4 VO 3 The solution is microwaved in a microwave oven for 3 minutes; the power of the microwave oven is 500W;

[0031] Step 4: The NH after microwave treatment 4 VO 3 The solution was transferred to a reactor lined with polytetrachloroethylene and placed in a micro-ultra-high pressure hydrothermal reactor for hydrothermal reaction at 140°C for 6 hours to obtain a suspension; among them, the pressure in the micro-ultra-high pressure hydrotherm...

Embodiment 2

[0035] Preparation of ultra-thin nano flake NH by ultra-high pressure 4 V 3 O 8 The nanomaterial method includes the following steps:

[0036] Step 1: Add 0.15g of 1-methyl-3-ethylimidazole chloride to 10mL of water to dissolve, and then add 0.1g of ethylenediaminetetraacetic acid and stir to form a mixed solution;

[0037] Step 2: Add 10 mL of 50% glycerol to the mixed solution and then add 0.5 g of NH 4 VO 3 And heating to make NH 4 VO 3 Fully dissolved into NH 4 VO 3 Solution; Among them, the heating temperature is 40℃;

[0038] Step 3: Put NH 4 VO 3 The solution is microwaved in a microwave oven for 4 minutes; the power of the microwave oven is 600W;

[0039] Step 4: The NH after microwave treatment 4 VO 3 The solution was transferred to a reactor lined with polytetrachloroethylene and placed in a micro ultrahigh pressure hydrothermal reactor for 4h hydrothermal reaction at 150℃ to obtain a suspension; among them, the pressure in the micro ultrahigh pressure hydrothermal reactor wa...

Embodiment 3

[0042] Preparation of ultra-thin nano flake NH by ultra-high pressure 4 V 3 O 8 The nanomaterial method includes the following steps:

[0043] Step 1: Add 0.2g of 1-methyl-3-ethylimidazole chloride to 10mL of water to dissolve, and then add 0.1g of ethylenediaminetetraacetic acid and stir to form a mixed solution;

[0044] Step 2: Add 6mL of 50% methanol to the mixed solution and then add 0.43g of NH 4 VO 3 And heating to make NH 4 VO 3 Fully dissolved into NH 4 VO 3 Solution; Among them, the heating temperature is 30℃;

[0045] Step 3: Put NH 4 VO 3 The solution is microwaved in a microwave oven for 2 minutes; the power of the microwave oven is 700W;

[0046] Step 4: The NH after microwave treatment 4 VO 3 The solution was transferred to a reactor lined with polytetrachloroethylene and placed in a micro ultra-high pressure hydrothermal reactor for hydrothermal reaction at 170°C for 5 hours to obtain a suspension; among them, the pressure in the micro ultra-high pressure hydrothermal r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com