Preparation method of granular dibutyltin oxide

A dibutyltin oxide, state technology, applied in the direction of tin organic compounds, can solve the problems of personnel and environmental hazards, small specific gravity, fine particle size, etc., and achieve the effects of low operating intensity, low cost, and large production capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

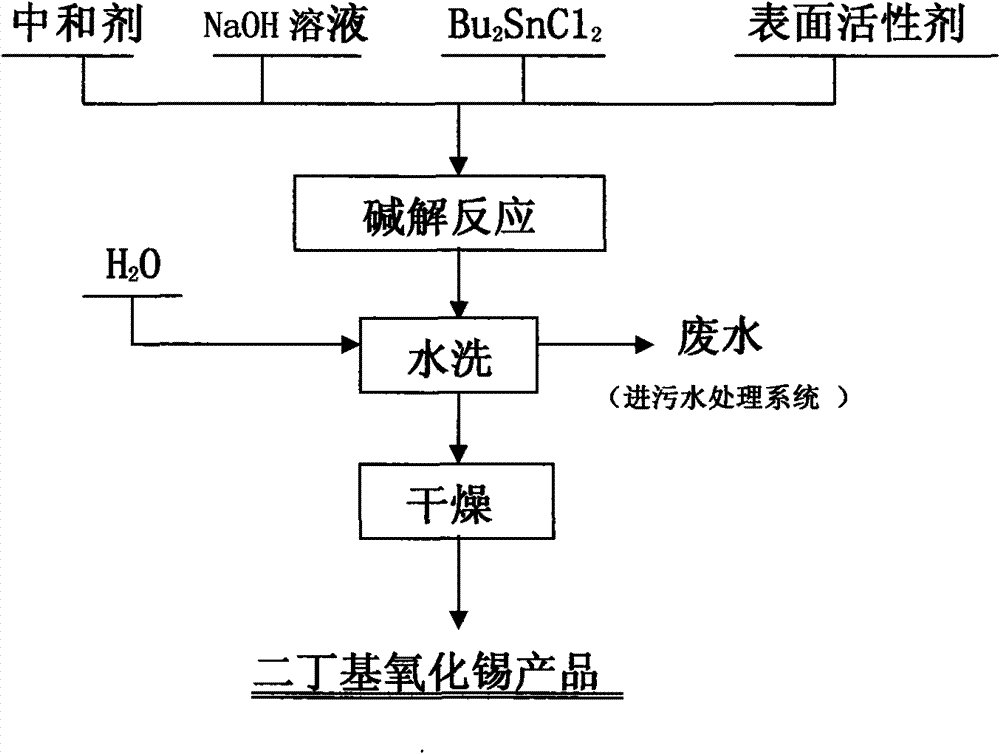

Method used

Image

Examples

Embodiment 1

[0016] Embodiment 1: 5000kg concentration is that 20% sodium hydroxide, 85kg ammoniacal liquor and tensio-active agent 8.5kg add in the reactor, be warming up to 60 ℃ of initial reaction temperatures, then slowly add dropwise 3500kg dibutyl tin chloride, control The temperature is 60°C at the starting temperature of the alkaline hydrolysis reaction. After adding dibutyltin dichloride dropwise, control the temperature at 60-70°C and react for 2 hours to do one reaction. After the constant temperature is over, the brine is pumped away. Add 4000kg of hot water at 60°C, 200kg of ammonia water and 1kg of surfactant for the second reaction, control the temperature at 60-70°C for 2 hours, add 4000kg of hot water at 60°C, 80kg of ammonia water and 1kg of surfactant for the third reaction, and control the temperature at 60-70 °C for 2 hours. After the reaction, the dibutyltin oxide product was repeatedly washed three times with hot water at 60°C, centrifugally filtered, and dried in a...

Embodiment 2

[0017] Embodiment 2: 5200kg concentration is that 15% sodium hydroxide, 80kg ammoniacal liquor and 8kg tensio-active agent are added in the reactor, be warmed up to initial reaction temperature 55 ℃, then slowly dropwise add 2950kg dibutyl tin chloride, control temperature The initial temperature of alkaline hydrolysis reaction is 55°C. After adding dibutyltin dichloride dropwise, control the temperature at 60-70°C and react for 2.5 hours for one reaction. After the constant temperature is over, the brine is pumped away. Add 4000kg of hot water at 60°C, 180kg of ammonia water and 1kg of surfactant for the second reaction, and react at a temperature of 60-70°C for 2 hours. °C for 2 hours. After the reaction, the dibutyltin oxide product was repeatedly washed 4 times with hot water at 60°C, centrifugally filtered, and dried in a vacuum dryer at 80-90°C for 24 hours to obtain 2385kg of qualified dibutyltin oxide product. The obtained product quality: main content: 99.62%; Sn: 4...

Embodiment 3

[0018] Embodiment 3: 6660kg concentration is that 15% sodium hydroxide, 100kg ammoniacal liquor and 10kg tensio-active agent are added in the reactor, be warming up to initial reaction temperature 50 ℃, then slowly dropwise add 3500kg dibutyl tin chloride, control temperature The initial temperature of alkaline hydrolysis reaction is 50°C. After adding dibutyltin dichloride dropwise, control the temperature at 60-70°C and react for 2 hours to do one reaction. After the constant temperature is over, the brine is pumped away. Add 4000kg of hot water at 60°C, 150kg of ammonia water and 1kg of surfactant for the second reaction, and react at a temperature of 60-70°C for 1 hour. °C for 1 hour. After the reaction, the dibutyltin oxide product was repeatedly washed with hot water at 60°C for 3 times, centrifugally filtered, and dried in a vacuum dryer at 80-90°C for 24 hours to obtain 2842kg of qualified dibutyltin oxide product. The quality of the obtained product: main content: 9...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com