Production technology of uniformly-knitted transparent four-way silk stocking wrapping yarn

A production process and technology of covering yarn, applied in the direction of yarn, socks, spinning machine, etc., can solve the problems of poor permeability of stockings, uneven wearing, insufficient feel and softness of stockings, etc., to maintain the feel and softness of stockings. The effect of eliminating uneven wearing and even wearing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

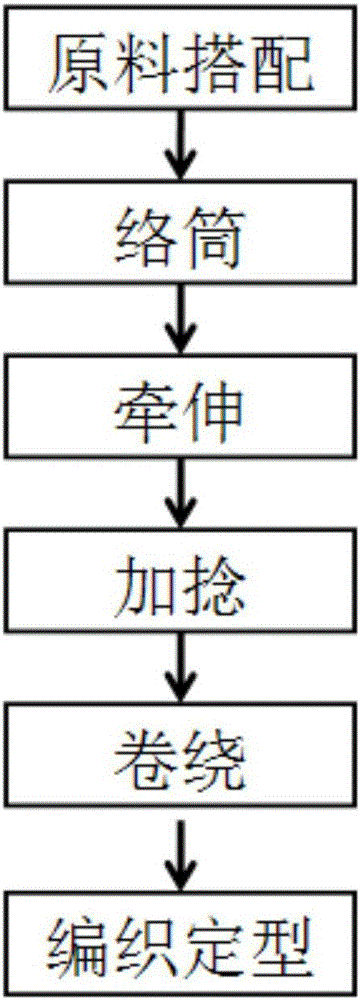

Method used

Image

Examples

Embodiment 1

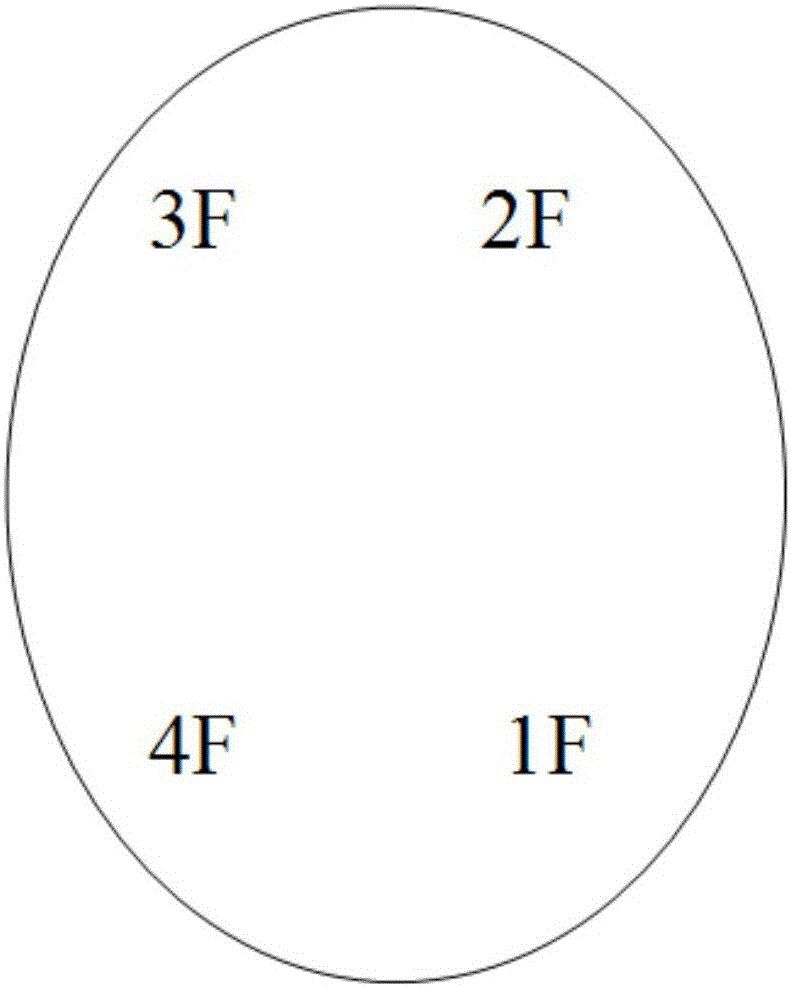

[0047] 1. Raw material matching

[0048] Raw material matching is a very important step in the present invention. After many tests, the present invention selects two lines of spandex yarns with a fineness of 20D-70D, which is called the first group. In this embodiment, the conventional fineness of 20D is taken as an example. The fineness of the other two lines of spandex yarns is 10D-15D, which is called the second group. In this embodiment, the fineness of 10D is taken as an example. Nylon yarn for outsourcing can choose the same fineness, generally 5D-12D, or the nylon yarn of the first group can be slightly thicker than that of the second group. Considering the situation of reducing snags during hosiery knitting and wearing, if the second group adopts the low-twist processing method, the nylon yarn of the second group should choose nylon yarn with the same fineness and low number of holes. The present invention takes FDY 10D / 5F nylon yarn as an example, if the second group...

Embodiment 2

[0069] A production process for weaving uniform and transparent four-way silk stocking covering yarn, comprising the following steps:

[0070] 1) Raw material matching: the first group uses 20D ordinary spandex yarn as the core, and covers it with FDY 8D / 5F nylon yarn, that is, the specification of the covering yarn is 2008 / 5; the second group uses 10D ordinary spandex yarn as the core, and uses The nylon yarn of FDY8D / 5F is covered, that is, the specification of the covered yarn is 1008 / 5;

[0071] 2) Winding: Winding is carried out according to the conventional process;

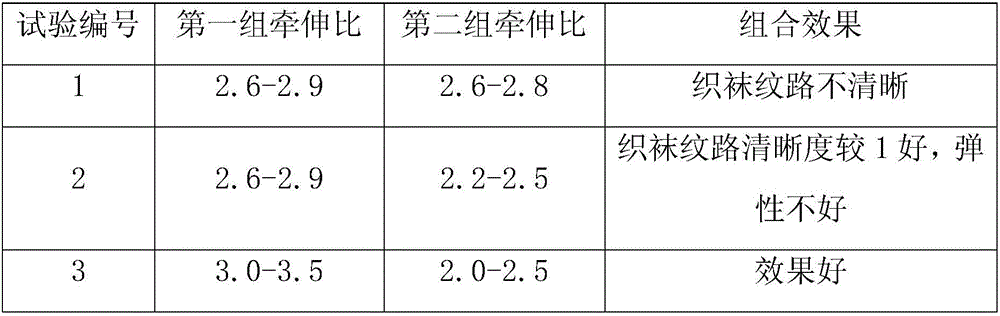

[0072] 3) Drafting: the drafting ratio of the first group of covered yarns 2008 / 5 is set to 3.4, and the drafting ratio of the second group of 1008 / 5 is set to 2.2;

[0073] 4) Twisting: the twists of the two sets of covered yarns are all set to 1800;

[0074] 5) Winding: Winding is carried out according to the conventional process, and the winding rate is set to 90%;

[0075] 6) Knitting and shaping: pu...

Embodiment 3

[0077] A production process for weaving uniform and transparent four-way silk stocking covering yarn, comprising the following steps:

[0078] 1) Raw material matching: the first group uses 20D anti-stripping spandex yarn as the core, and covers it with FDY 12D / 24F nylon yarn, that is, the specification of the covering yarn is 2012 / 24; the second group uses 10D anti-stripping spandex yarn as the core , covered with FDY12D / 24F nylon yarn, and the specification of covered yarn is 1012 / 24.

[0079] 2) Winding: winding according to the conventional process

[0080]3) Drafting: the draft ratio of the first group of covered yarns 2012 / 24 is set to 3.4, and the draft ratio of the second group of 1012 / 24 is set to 2.2

[0081] 4) Twisting: the twist of the two sets of covered yarns is set to 1700

[0082] 5) Winding: Winding is carried out according to the conventional process, and the winding rate is set to 90%

[0083] 6) Knitting and shaping: Put two groups of covered yarns in a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com