Hard and soft integrated electronic product shell and preparation method thereof

A technology for electronic products and casings, which is applied in the field of soft and hard electronic product casings and its preparation, which can solve the problems of elastic bodies that are easily deformed by force, joints that are easy to break, and contact areas that are small, etc., to achieve consistency The effect of non-resistance, not easy to disengage, and excellent rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to further understand the present invention, the preferred embodiments of the present invention are described below in conjunction with the examples, but it should be understood that these descriptions are only for further illustrating the features and advantages of the present invention rather than limiting the patent requirements of the present invention.

[0036] The present invention provides a soft-hard electronic product housing, comprising:

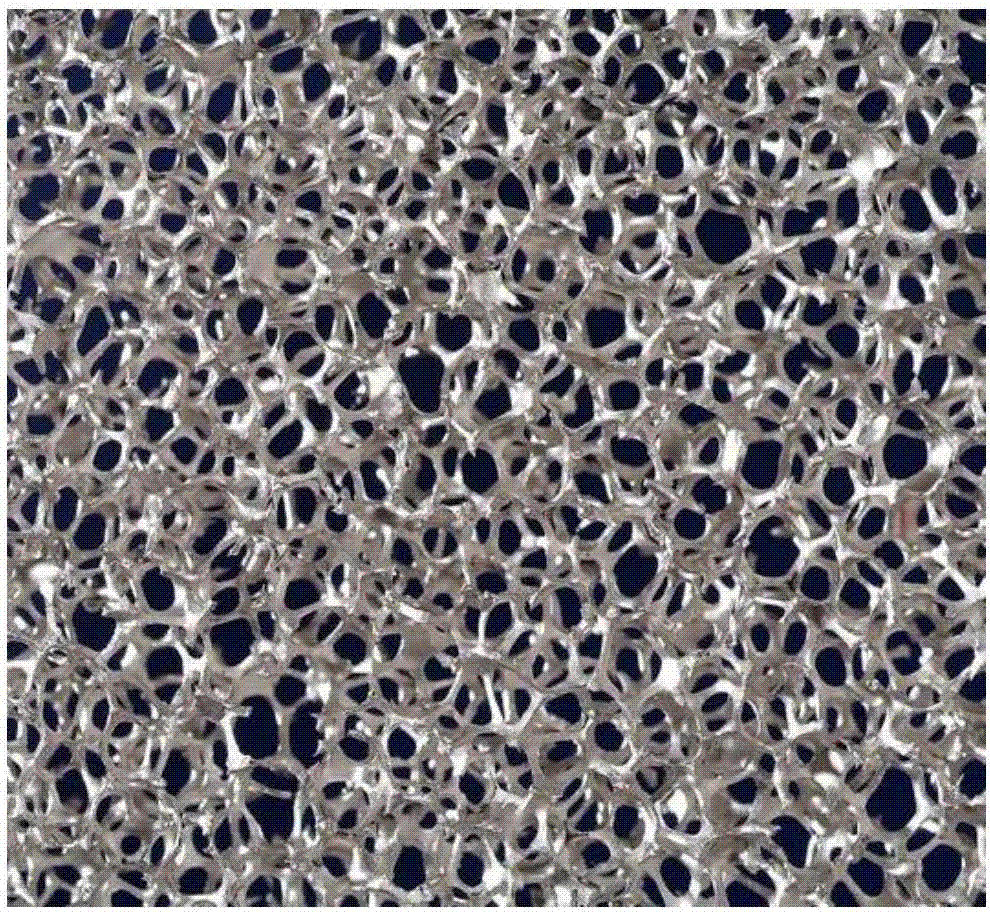

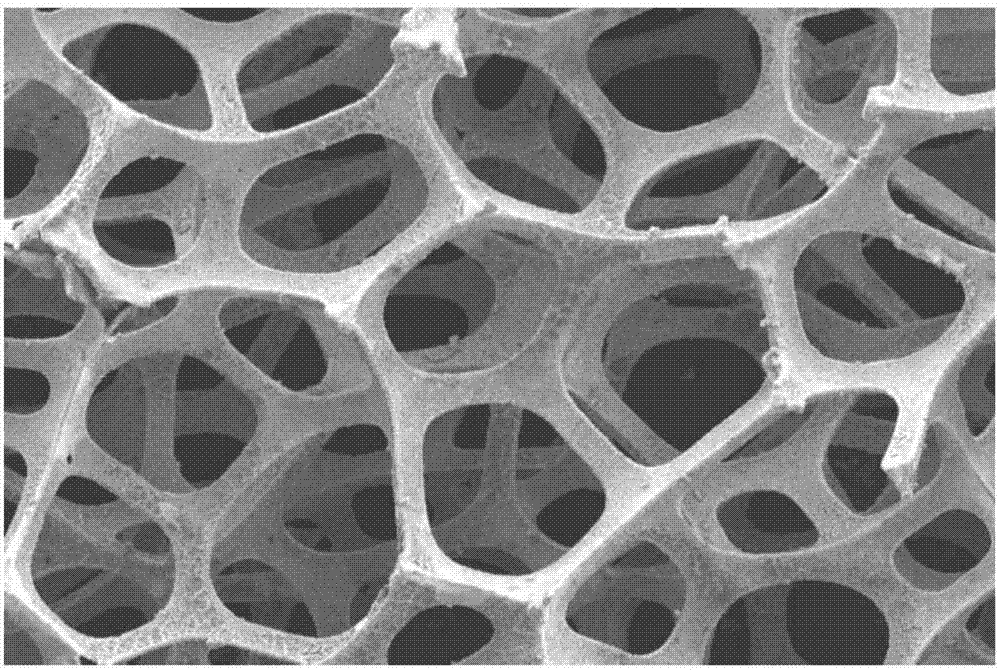

[0037] The rigid part is composed of metal foam, and the flexible part is composed of polymer elastic body; the metal foam and the polymer elastic body are fixedly connected.

[0038] The housing of the electronic product provided by the invention adopts metal foam to provide a rigid framework, and has excellent rigidity.

[0039] In the present invention, there is no special limitation on the metal type of the metal foam, and high-rigidity metals well known to those skilled in the art can be used.

[0040] The pre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com