Vehicle-mounted measurement device of three-dimensional deformation monitoring of subway tunnels based on reference transmission

A technology of reference transmission and three-dimensional deformation, which is applied in the direction of measuring devices, optical devices, signal transmission systems, etc., can solve problems such as low monitoring efficiency, tunnel damage, and poor monitoring accuracy, so as to save manpower, material resources, time, and stability Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0080] In order to make the object, technical solution and advantages of the present invention more clear, the present invention will be further described in detail below in conjunction with the examples. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

[0081] The hardware and software environment required by the present invention are basically possessed, and at present, there are ground dynamic data acquisition vehicles and various ground laser scanners.

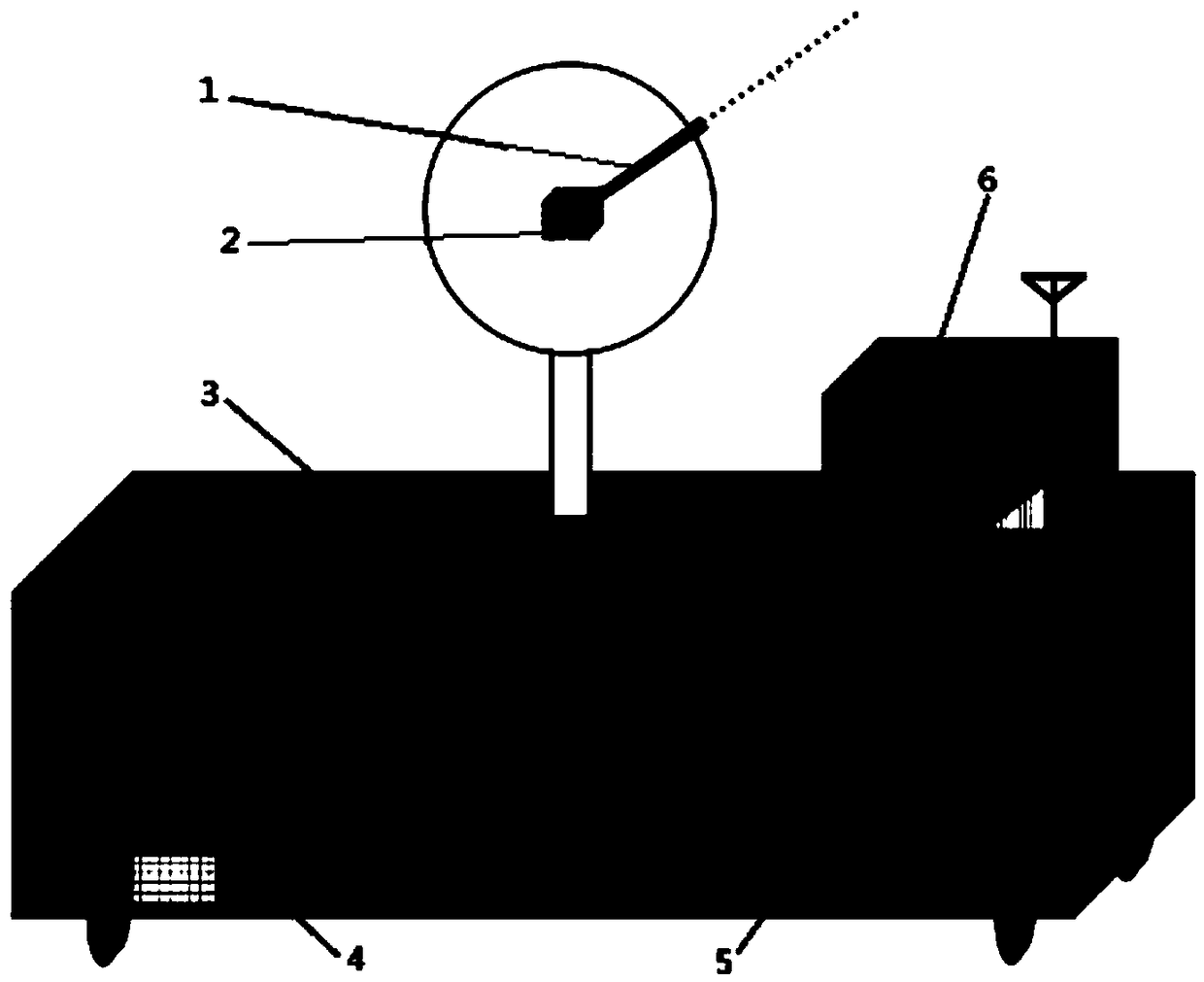

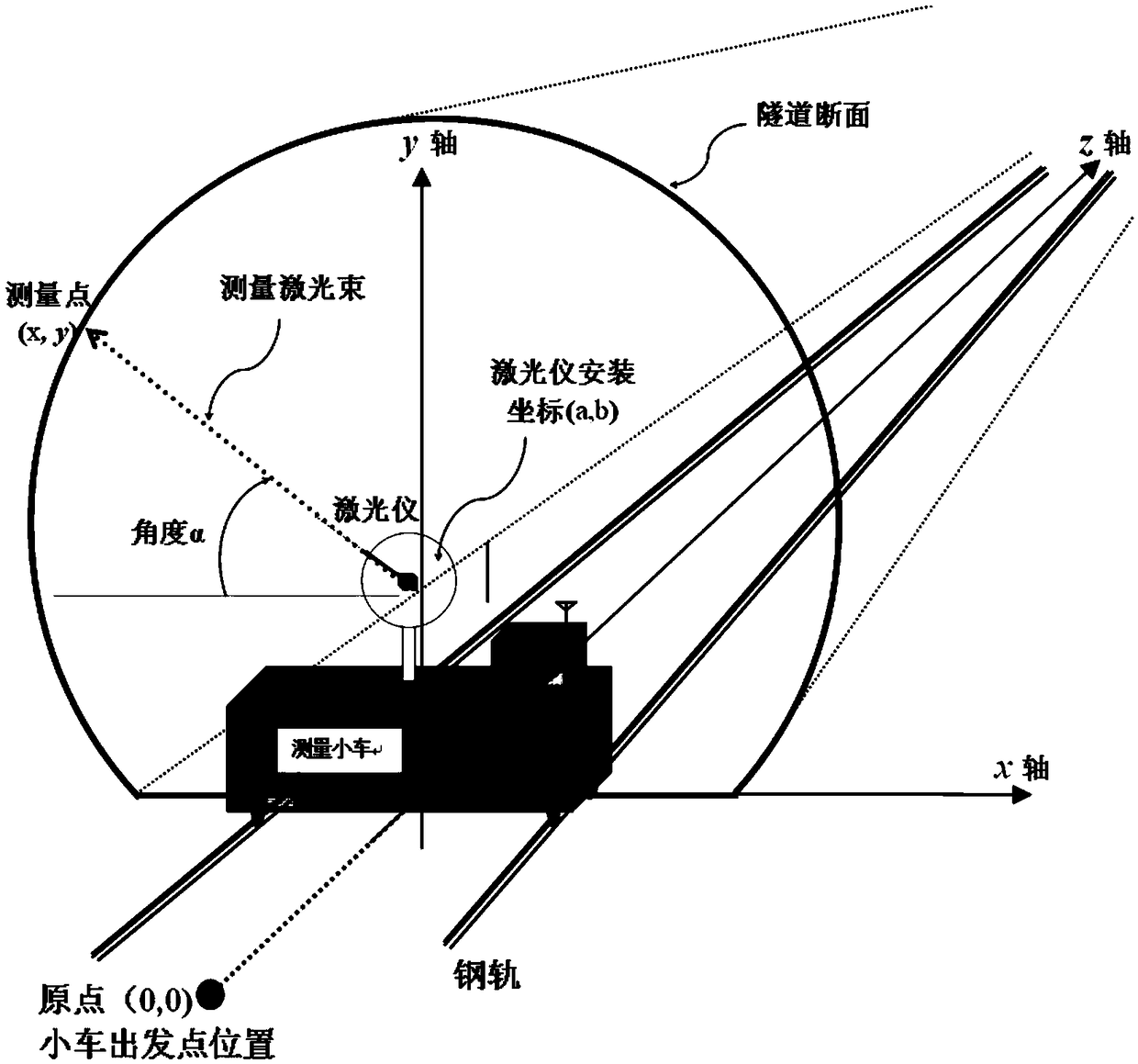

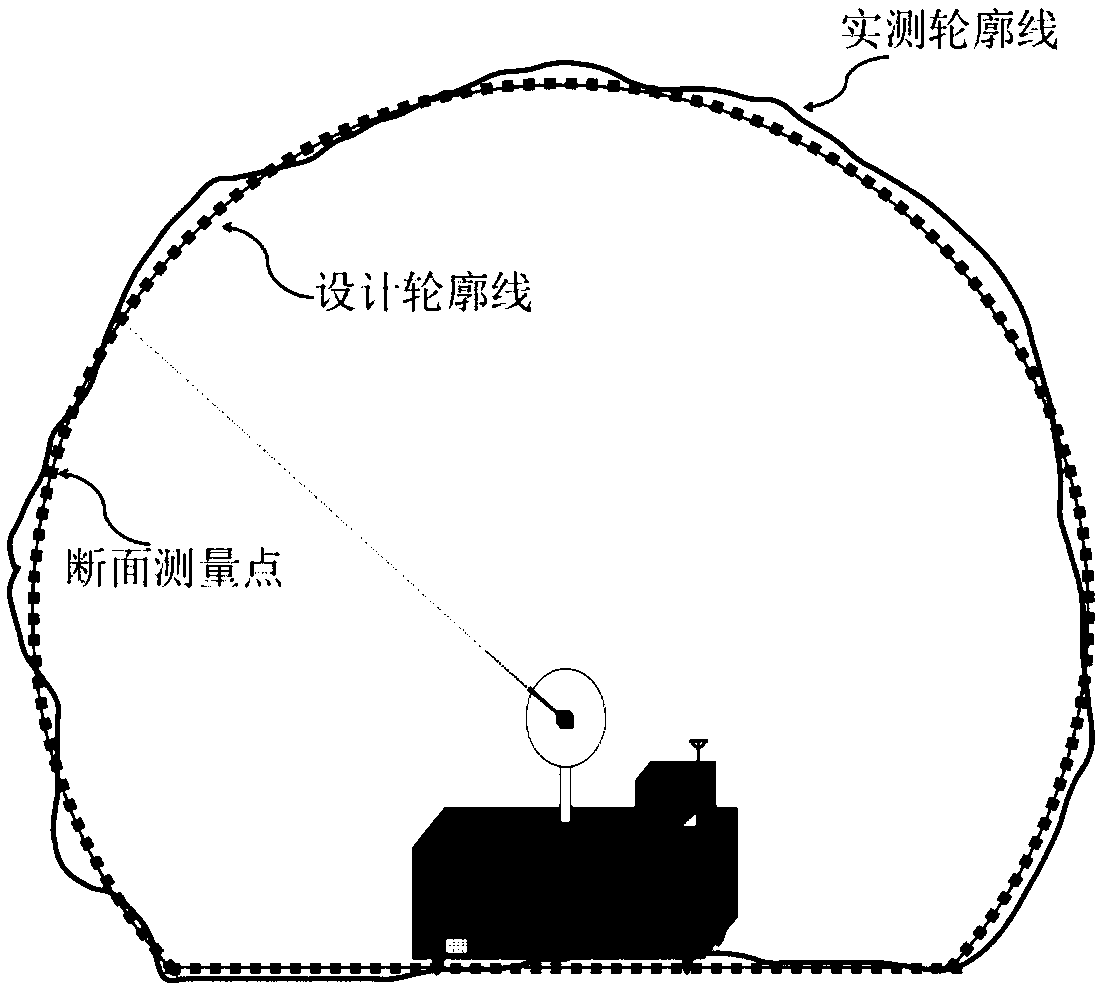

[0082] Such as figure 1 The on-board measurement device for three-dimensional deformation monitoring of subway tunnels based on reference transfer provided by the embodiments of the present invention includes:

[0083] Laser rangefinder 1, inclination sensor 2, high-precision rotary table 3, photoelectric encoder 4, PLC controller 5 and wireless communicator 6;

[0084] Laser rangefinder 1, inclination sensor 2, high-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com