Technological system and method for removing carbon, nitrogen and sulphur in waste water synchronously

A waste water and removal technology, applied in separation methods, sulfur preparation/purification, chemical instruments and methods, etc., can solve the problems of not being able to remove carbon, nitrogen and sulfur at the same time, the complex process of carbon, nitrogen and sulfur, and the difficulty of separating elemental sulfur, etc. Small footprint, easy operation, no secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

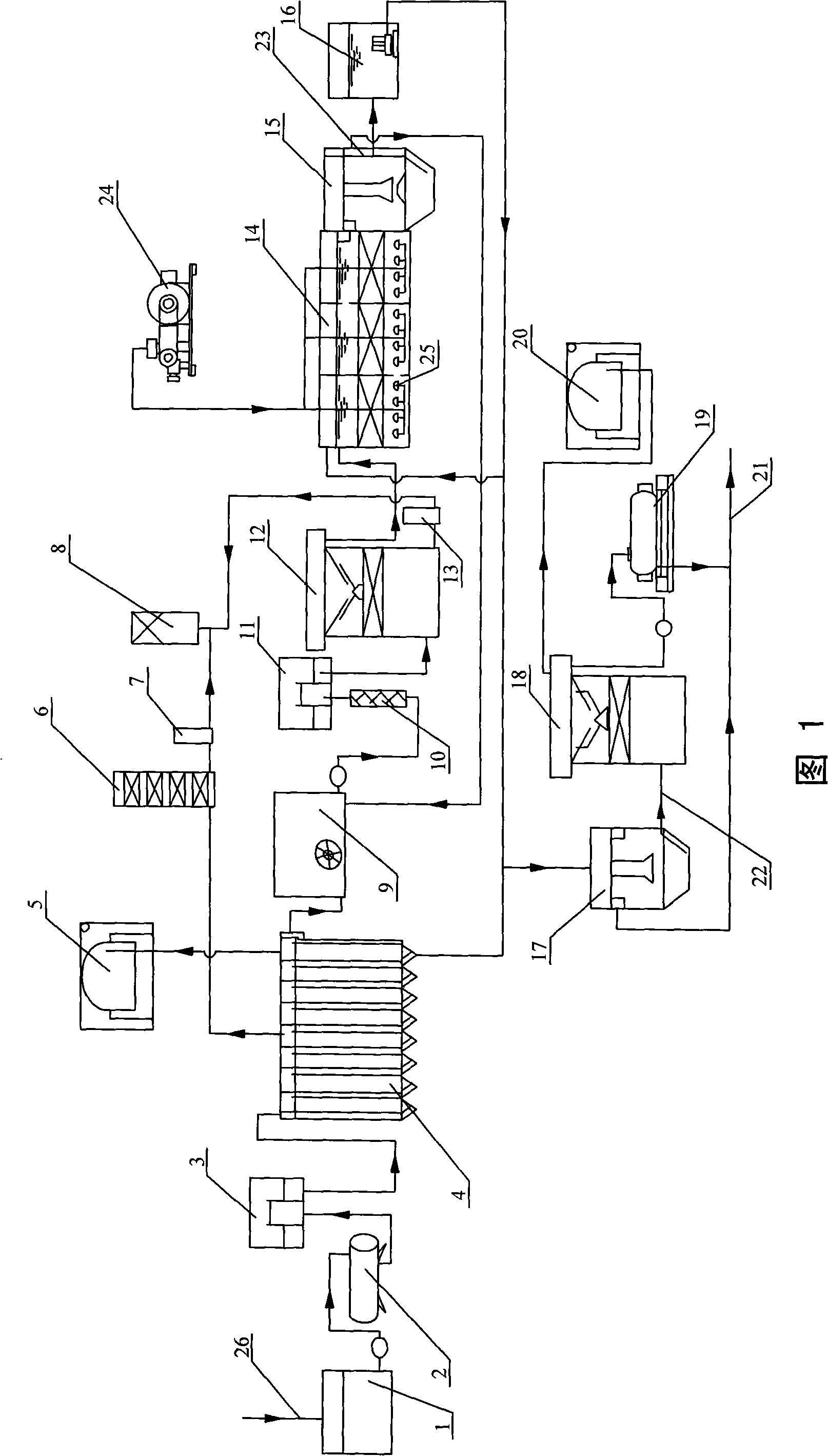

[0010] Specific embodiment 1: illustrate in conjunction with Fig. 1, the process system of synchronously removing carbon, nitrogen and sulfur in wastewater in this embodiment is composed of regulating tank 1, first heat exchanger 2, first lifting well 3, sulfate reduction and organic matter Removal device 4, first biogas storage tank 5, biological deodorization tower 6, first elemental sulfur separation device 7, elemental sulfur recovery device 8, mixing tank 9, second heat exchanger 10, second lifting well 11, carbon nitrogen sulfur Synchronous removal device 12, second elemental sulfur separation device 13, nitrification reactor 14, sedimentation tank 15, mud collection well 16, concentration tank 17, anaerobic sludge nitrification device 18, sludge centrifugation device 19, second biogas storage Tank 20, discharge pipe 21, connecting pipe 22, siphon pipe 23, blower 24, aeration head 25 and water inlet pipe 26 are formed; The water inlet at the top of the first heat exchang...

specific Embodiment approach 2

[0012]Specific embodiment two: the difference between this embodiment and specific embodiment one is that the sulfate reduction and organic matter removal device 4 is the integration described in the patent No. ZL 00206243.7 (its announcement number is CN2420272, and the announcement date is 2001.02.21) Two-phase anaerobic biological treatment reactor or anaerobic baffled reactor. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0013] Specific embodiment three: the difference between this embodiment and specific embodiment one is that the carbon, nitrogen and sulfur synchronous removal device 12 is the reaction described in Chinese Patent Application No. 200710072195.0 (its publication number is CN101050031, and the disclosure date is 2007.10.10) reactor or granular sludge expanded bed reactor.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com