Chemical bulk stack dipping process for gold-containing tailing ore without pelletizing

A tailings and loosening technology, applied in the field of hydrometallurgy, can solve the problems of inability to directly produce finished gold, difficulty in utilizing low-grade ore, high production cost, etc. And the effect of low production conditions, easy handling and stacking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

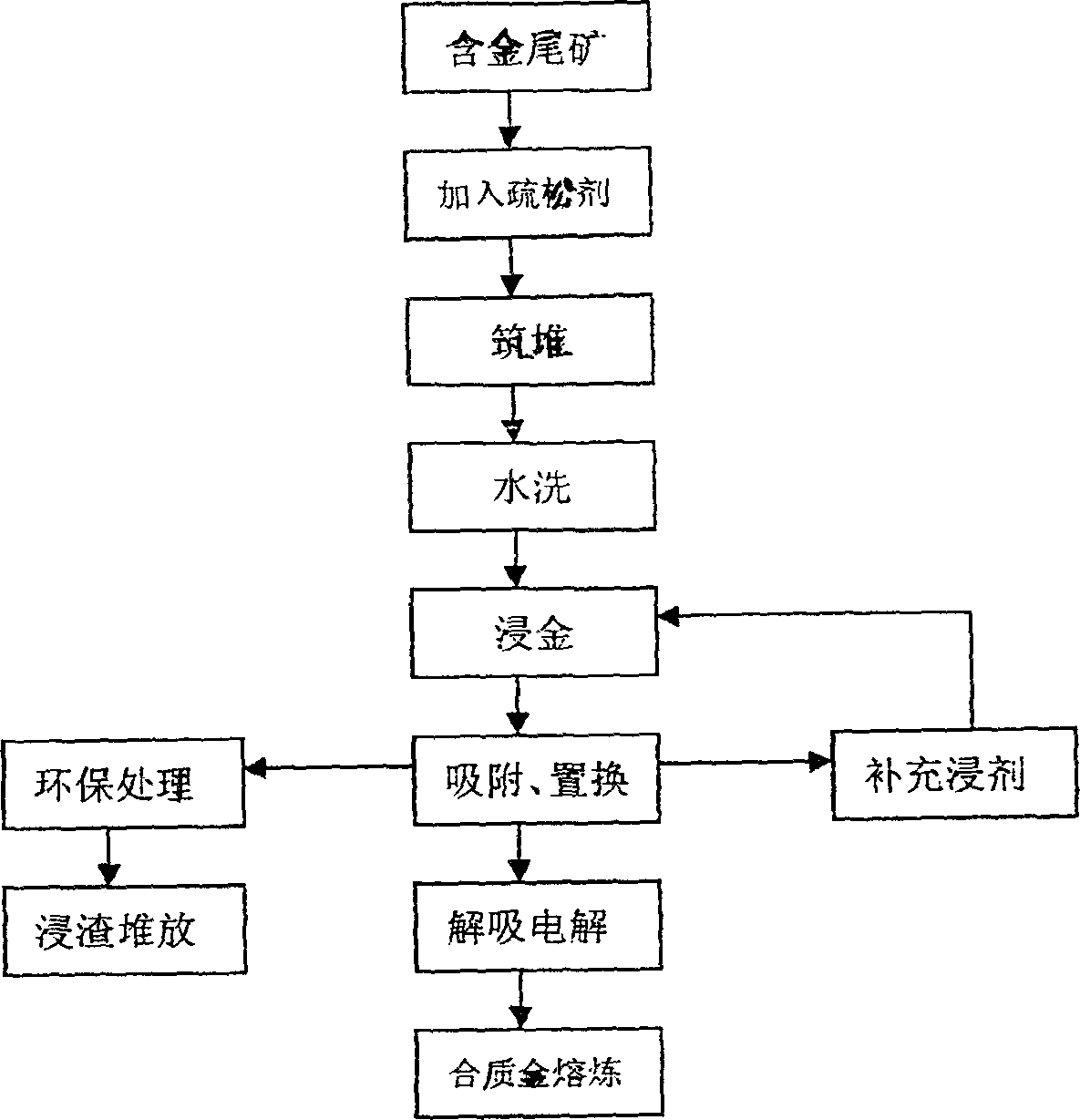

[0017] Referring to the accompanying drawings, an on-site implementation process of the present invention is as follows:

[0018] ①Material preparation: Add calcium oxide loosening agent accounting for 0.5-5.0% of the total weight of the tailings to the gold-bearing tailings to be treated, and then add (or not add) to the mineral material according to the composition of the tailings. A small amount of sodium phenoxylate wetting agent with a value of 0.01%, and then mix the mineral materials well for subsequent use;

[0019] ②Gold leaching site setting: Design the required site area according to the amount of tailings to be processed. The site is required to be flat and inclined laterally or oppositely. The inclination angle is 3-7°. 1-2 layers of water-proof materials are laid on the site. The water-proof material can be PVC soft board, plastic cloth, asphalt felt and other materials, and the joints should be laminated, welded or bonded, and no leakage is required; pebbles and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com