Method for laser-assisted ultrasonic rolling for surface modification

A technology of ultrasonic rolling and surface modification, applied in metal processing and other directions, can solve the problems of energy loss, expensive lubrication costs, workpiece deformation, etc., to achieve stable residual compressive stress, avoid large-area heating, and deep surface nanometerization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

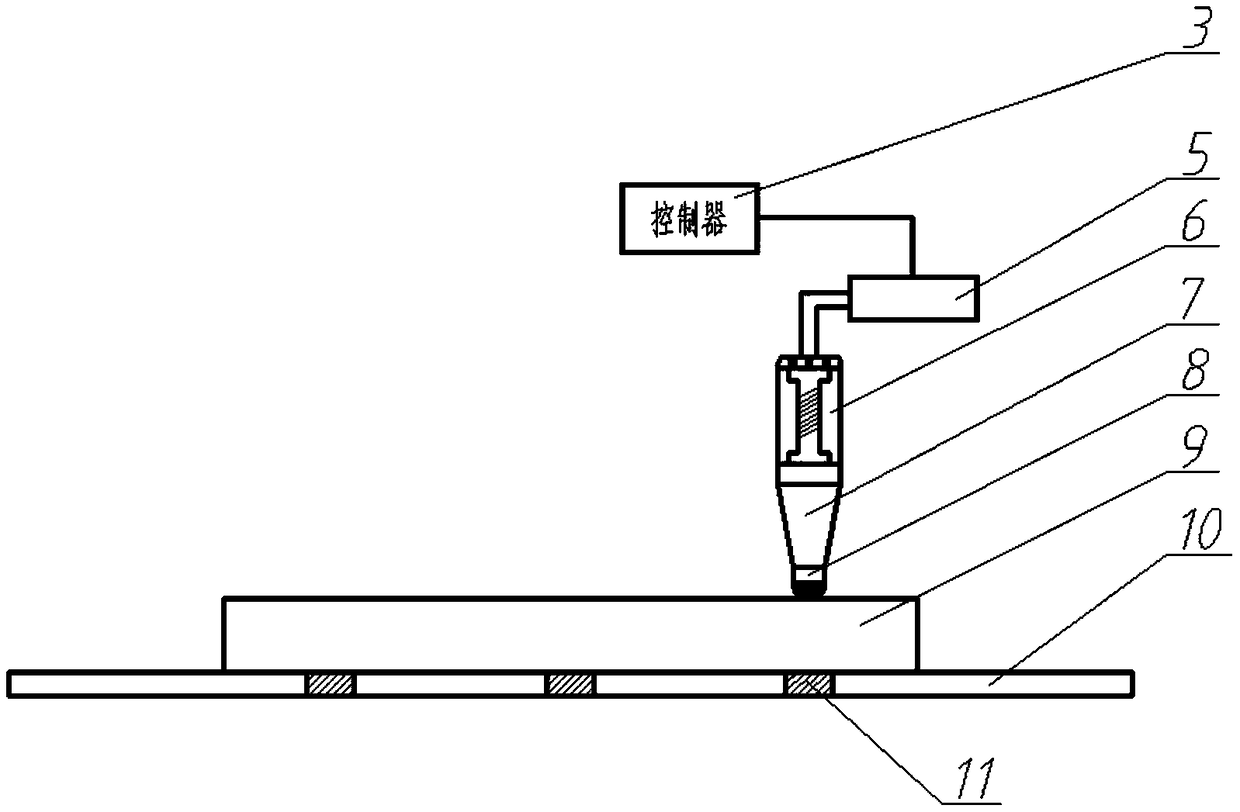

[0028] Such as figure 1 As shown, the metal workpiece is fixed on the workbench with a fixture, and the ultrasonic rolling device is used, and the above-mentioned ultrasonic rolling process parameters are used to perform ultrasonic rolling treatment on the surface of the workpiece. Figure 4 The pre-planned path is shown to complete the surface modification of the workpiece.

Embodiment 2

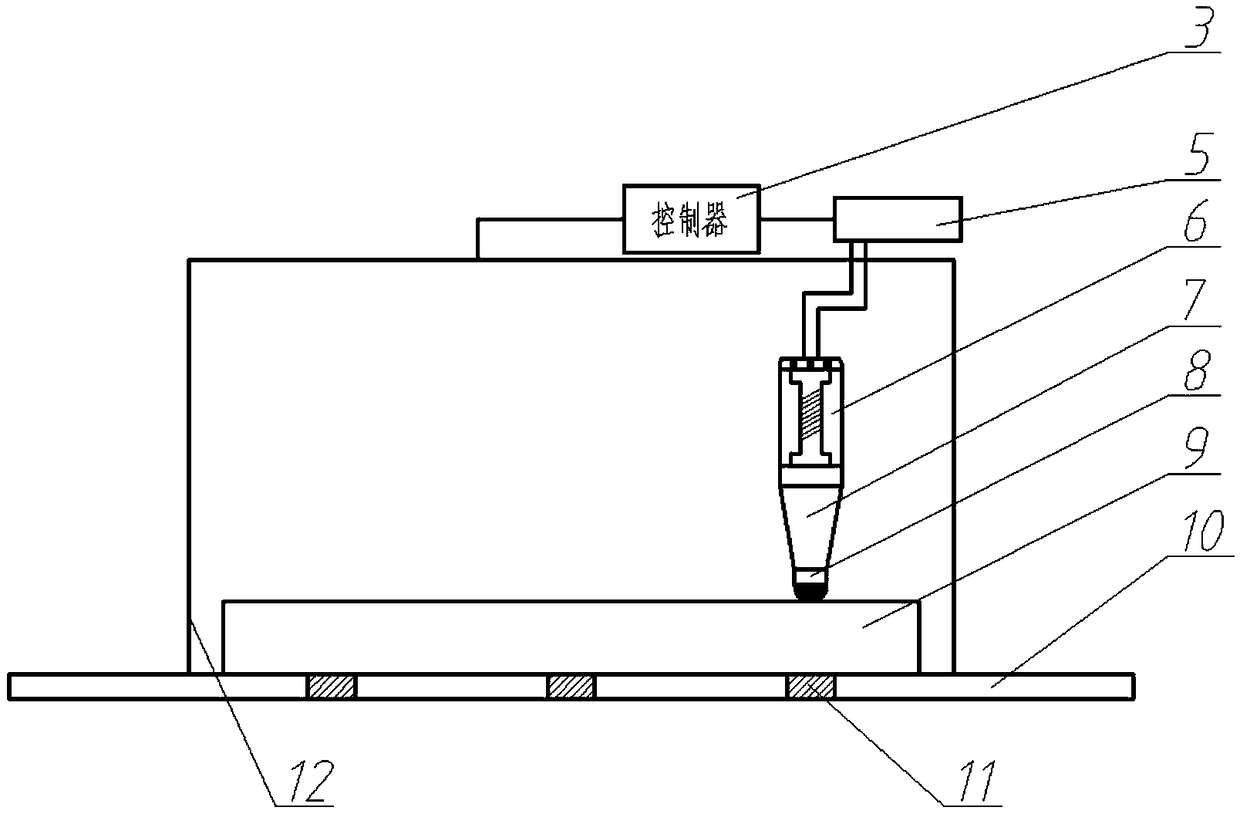

[0030] Such as figure 2 As shown, the metal workpiece is fixed on the workbench with fixtures and located in the heating device, the heating device is heated to 507.31 ° C, and kept at this temperature, and then the ultrasonic rolling device is used, and the above ultrasonic rolling process parameters are adopted. Ultrasonic rolling treatment is carried out on the surface of the workpiece, along the Figure 4 The pre-planned path is shown to complete the surface modification of the workpiece.

Embodiment 3

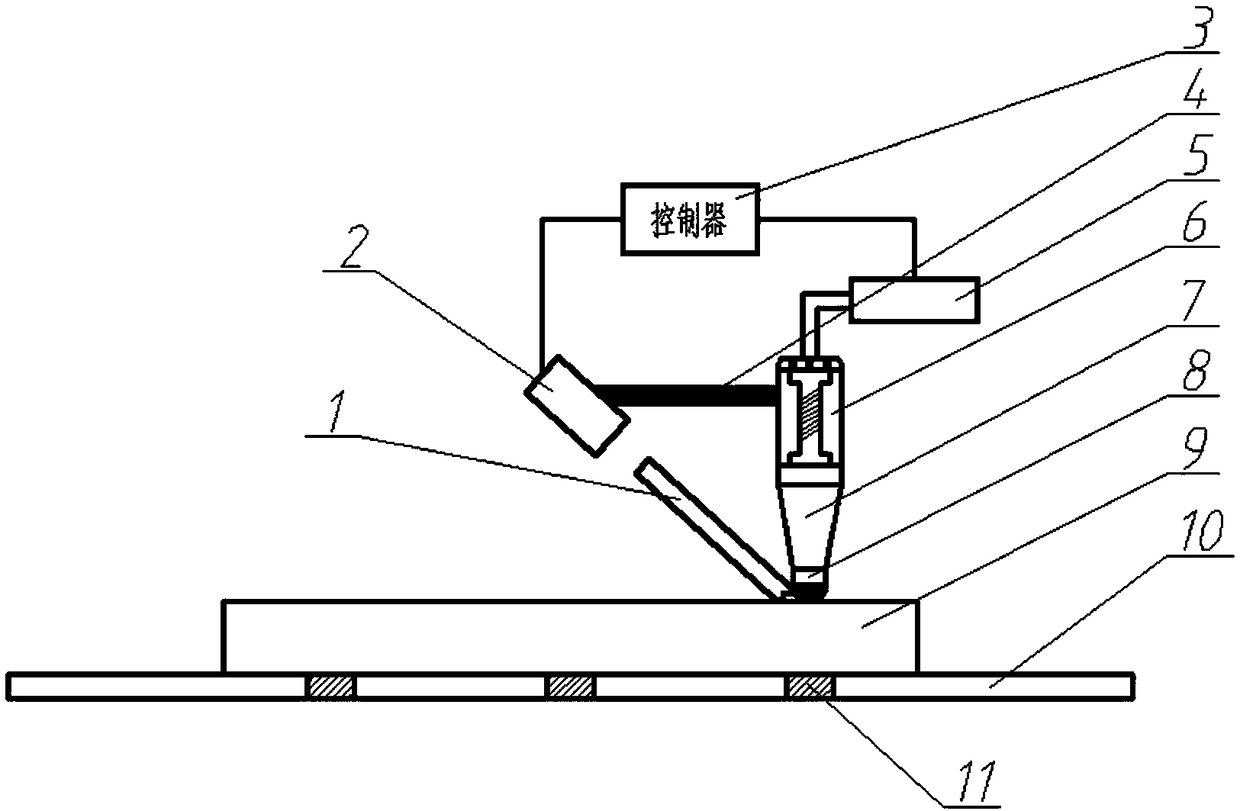

[0032] Technical scheme of the present invention, such as image 3 As shown, 1) fix the metal workpiece on the workbench with a fixture; 2) first use continuous laser beam to locally heat the surface of the metal workpiece to the dynamic recrystallization temperature of the metal workpiece 507.31 °C; 3) immediately use ultrasonic roller The pressing device uses the above-mentioned ultrasonic rolling process parameters to perform ultrasonic rolling treatment on the same position. In order to ensure simultaneous laser heating and ultrasonic rolling at the same position, the light outlet of the laser is connected to the ultrasonic unit. The two parts move together; 4) adopt the same operation steps, along such as Figure 4 The pre-planned path is shown to complete the surface modification of the workpiece.

[0033] Figure 5 It is the result schematic diagram after processing of three embodiments. It can be seen that the metal workpiece processed by laser-assisted ultrasonic r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com