Method for preparing niobium sputtering target

A sputtering target material and preparation process technology, applied in sputtering plating, metal material coating process, ion implantation plating, etc., can solve the problem of poor grain size uniform texture formation, product quality and Yield rate is not easy to control and other problems, to achieve the effect of solving the problem of grain uniformity and texture, fast film forming speed, and fine grain

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

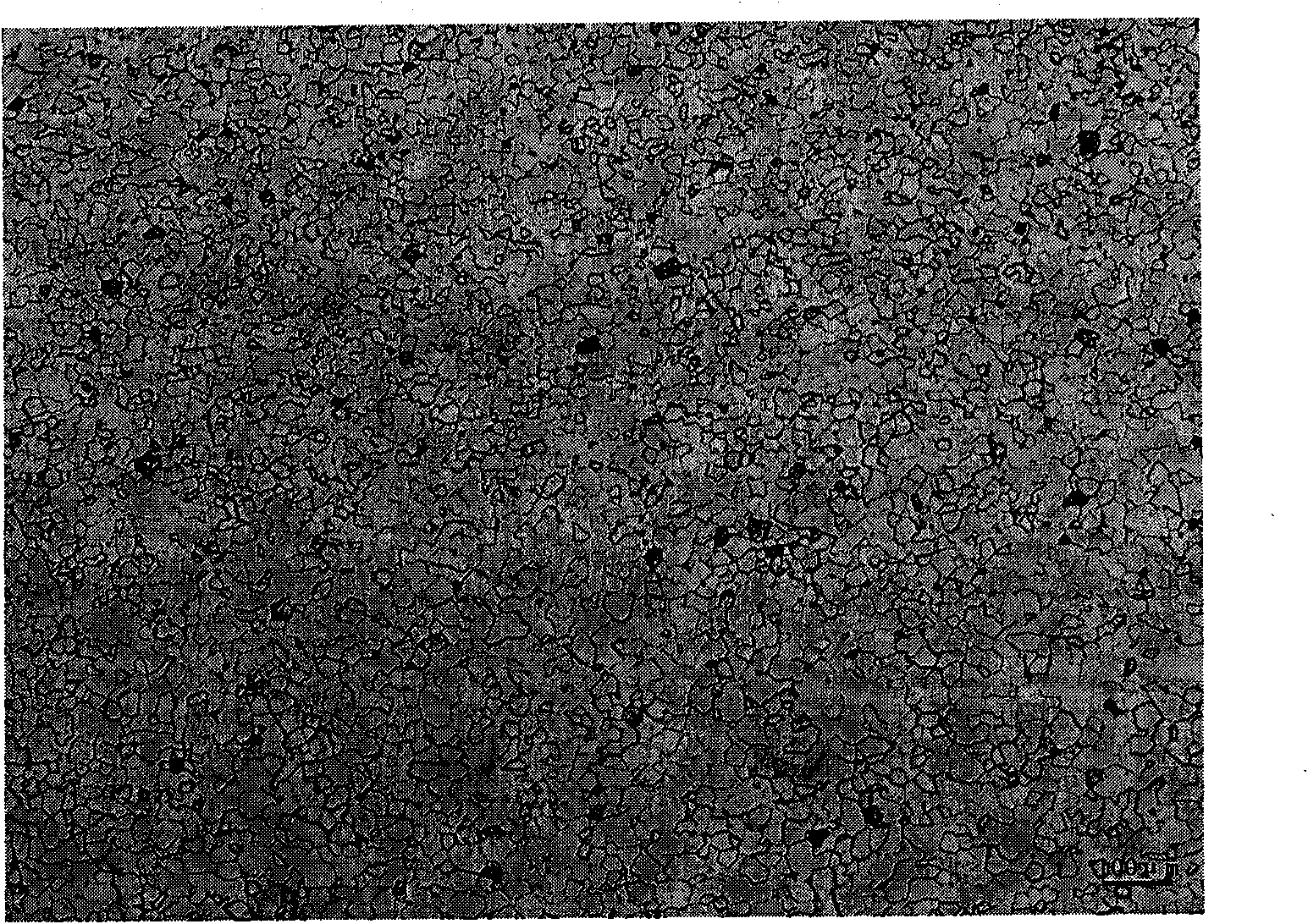

Embodiment 1

[0016] Melt a niobium ingot with a three-time electron beam with a specification of Φ330×600mm, heat it in an electric furnace to 700°C, keep it warm for 4 hours, heat it to 1100°C in an induction furnace after being out of the furnace, and extrude it into a horizontal extrusion machine to Φ120×L . Blanking to get Φ120×240mm niobium billet, heated to 500°C in an electric furnace, heat preservation for 1h, upsetting and forging on a 3T electro-hydraulic hammer to form a slab ≠60×150×300, and the single-pass processing rate of the first two hammers are greater than 30%. Then through rolling, 900°C, 2h intermediate annealing, 850°C, 1.5h finished annealing, wire cutting and other processes to obtain a finished niobium target ≠20×150×400. The grains of this niobium target are uniform and fine, the fine-grained area is 8.5, the coarse-grained area is 7, and the total amount of [111] texture reached 75% as measured by EBSD.

Embodiment 2

[0018] Melt a niobium ingot with a triple electron beam with a specification of Φ320×450mm, heat it in an electric furnace to 700°C, keep it warm for 4 hours, heat it to 950°C in an induction furnace after being out of the furnace, and then press it into a horizontal extrusion machine to extrude to Φ110×L . Blanking to get Φ110×215mm niobium billet, heated to 600°C in an electric furnace, heat preservation for 1h, upsetting and forging on a 3T electro-hydraulic hammer to form a slab of ≠45×130×350, wherein the single-pass processing rate of the first two hammers are greater than 30%. Then through rolling, 900°C, 2h intermediate annealing, 900°C, 1.5h finished annealing, wire cutting and other processes to obtain finished niobium target ≠6×130×700. The grains of the niobium target are uniform and fine, the fine-grained area is 8.5, and the coarse-grained area is 7.5. The total amount of [111] texture reached 90% as measured by EBSD.

Embodiment 3

[0020] Melt a niobium ingot with a three-time electron beam with a specification of Φ320×500mm, heat it in an electric furnace to 700°C, keep it warm for 4 hours, heat it to 1000°C in an induction furnace after being out of the furnace, and extrude it into a horizontal extrusion machine to Φ130×L . The niobium billet of Φ130×220mm is obtained by blanking, heated to 700°C in an electric furnace, kept for 1 hour, upsetting and forging on a 3T electro-hydraulic hammer to form a slab of ≠40×450×160, and the single-pass processing rate of the first three hammers is are greater than 30%. Then through rolling, 900°C, 2h intermediate annealing, 900°C, 1.5h finished annealing, wire cutting and other processes to obtain the finished niobium target of Φ450×8. The grains of the niobium target are uniform and fine, the fine-grained area is grade 7, and the coarse-grained area is grade 8.5. The total amount of [111] texture reached 72% as measured by EBSD.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com