Technique and apparatus for preparing particle reinforced aluminum-based composite material by reciprocating type extrusion

A particle-reinforced aluminum and composite material technology, which is applied in the field of preparation of particle-reinforced aluminum-based composite materials, can solve problems such as not involving the reciprocating extrusion device and processing technology of a single-cylinder press, and the inability to realize reciprocating extrusion of a single-cylinder press. Achieve the effect of reducing production cost, reducing labor intensity and wide application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

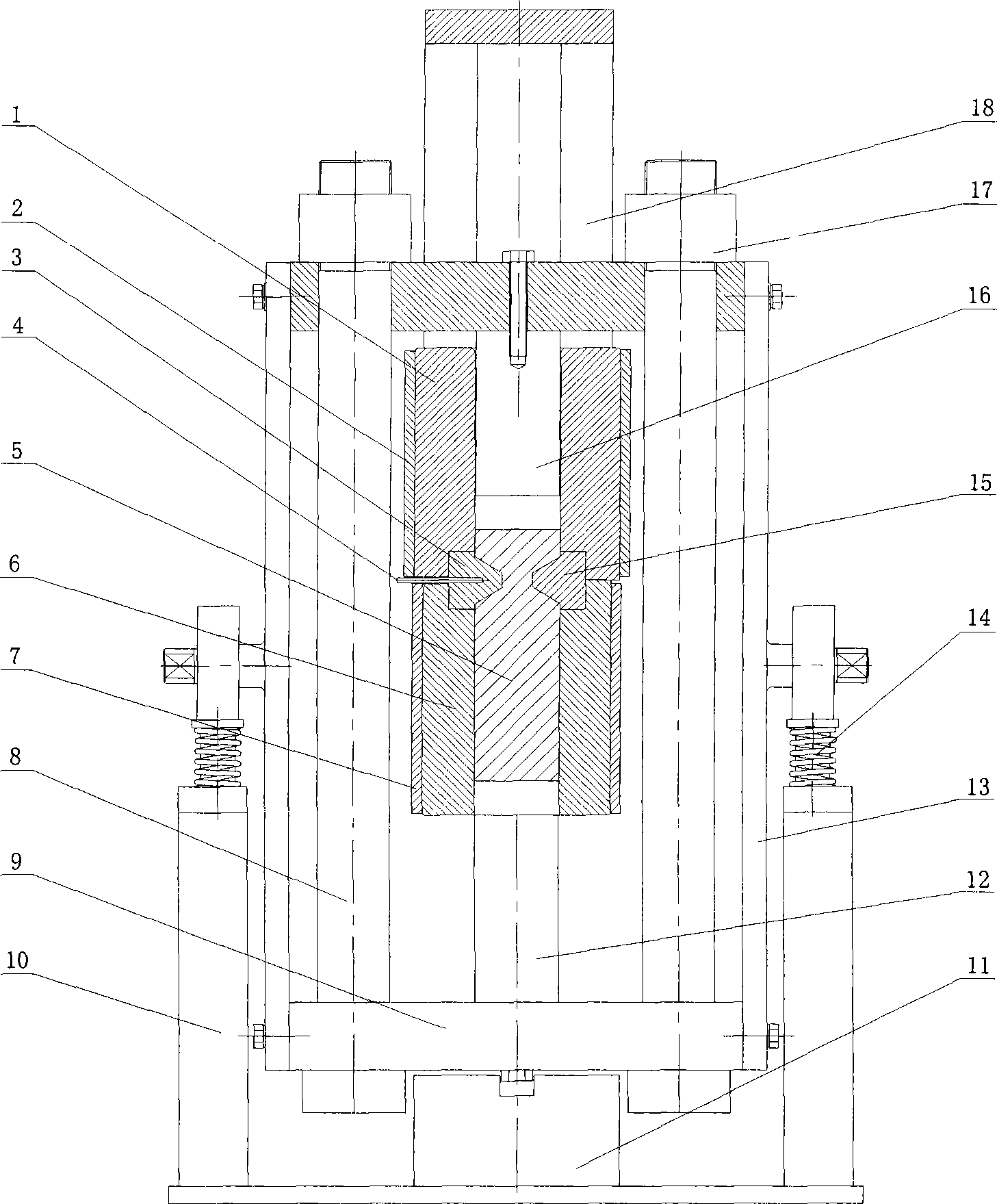

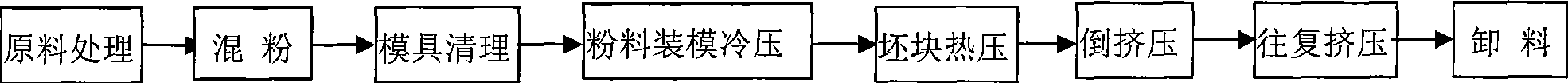

[0056] The preparation method for aluminum or aluminum alloy matrix composite material comprises the following steps:

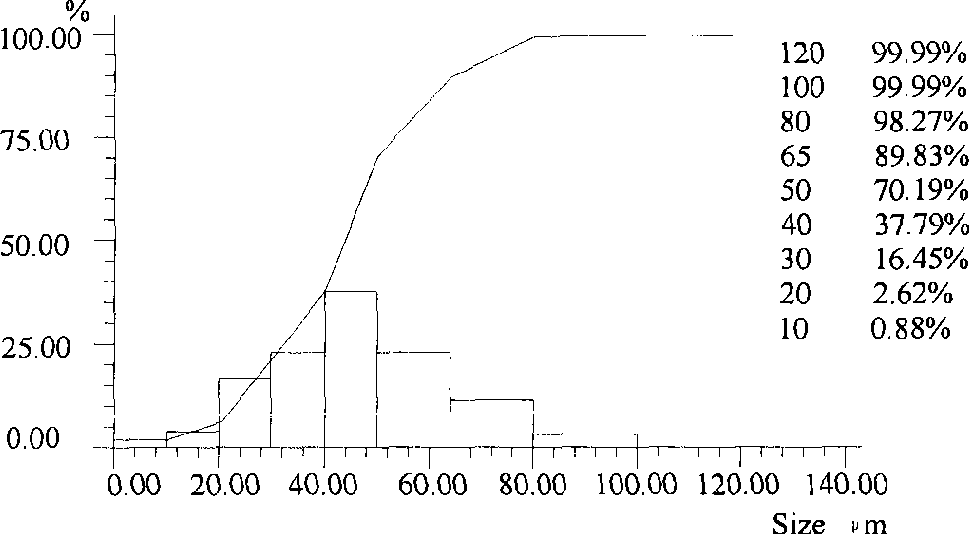

[0057] (1) Aluminum or aluminum alloy powder with a particle size of 40-150 μm and a reinforcing phase α-Al with a particle size of 25-150 μm and 5 vol.% to 25 vol.% 2 o 3p , Graphite powder and SiC are mechanically mixed in a mixer or ball mill until completely uniform;

[0058] (2) Do not add any solvent when dry mixing, add 2vol% absolute alcohol and 1wt% polyethylene glycol when wet mixing;

[0059] (3) Pack the mixed extruded mixed powder into the extrusion die consisting of upper and lower extrusion cylinders, and the loading amount is 50% of the volume of the upper and lower extrusion cylinders; The obtained powder should be dried in an oven first, and the temperature should be controlled at 60°C; use two positive molds to pressurize at both ends, and pre-press the mixed powder so that the powder fills the gap between the extrusion barrel and the mal...

Embodiment 1

[0065] Example 1 10% SiC p / Al composite material

[0066] According to the process discussed above, reciprocating extrusion 2 passes, the prepared 10% SiC p The tensile strength of the / Al composite material is >120MPa, and the elongation reaches 26%. Compared with pure aluminum, the tensile strength is nearly doubled, but the elongation does not decrease significantly.

Embodiment 2

[0067] Example 2 5vol.% Graphite-10vol.% Al 2 o 3 / Al composite material

[0068] According to the process discussed above, reciprocating extrusion 2 passes, the prepared 5vol.% graphite-10vol.% Al 2 o 3 / Al composite density can reach the theoretical density.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com