Method for determining Avrami mathematical model coefficient of metal dynamic recrystallization volume fraction

A volume fraction and mathematical model technology, applied in the direction of electrical digital data processing, special data processing applications, instruments, etc., can solve the problems of huge consumption of funds, heavy workload, poor applicability, etc., and achieve low sample consumption and low workload. The effect of low and simple calculation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0067] The invention provides a method for determining the coefficient of the Avrami mathematical model of the dynamic recrystallization volume fraction of a metal, and the specific steps are as follows:

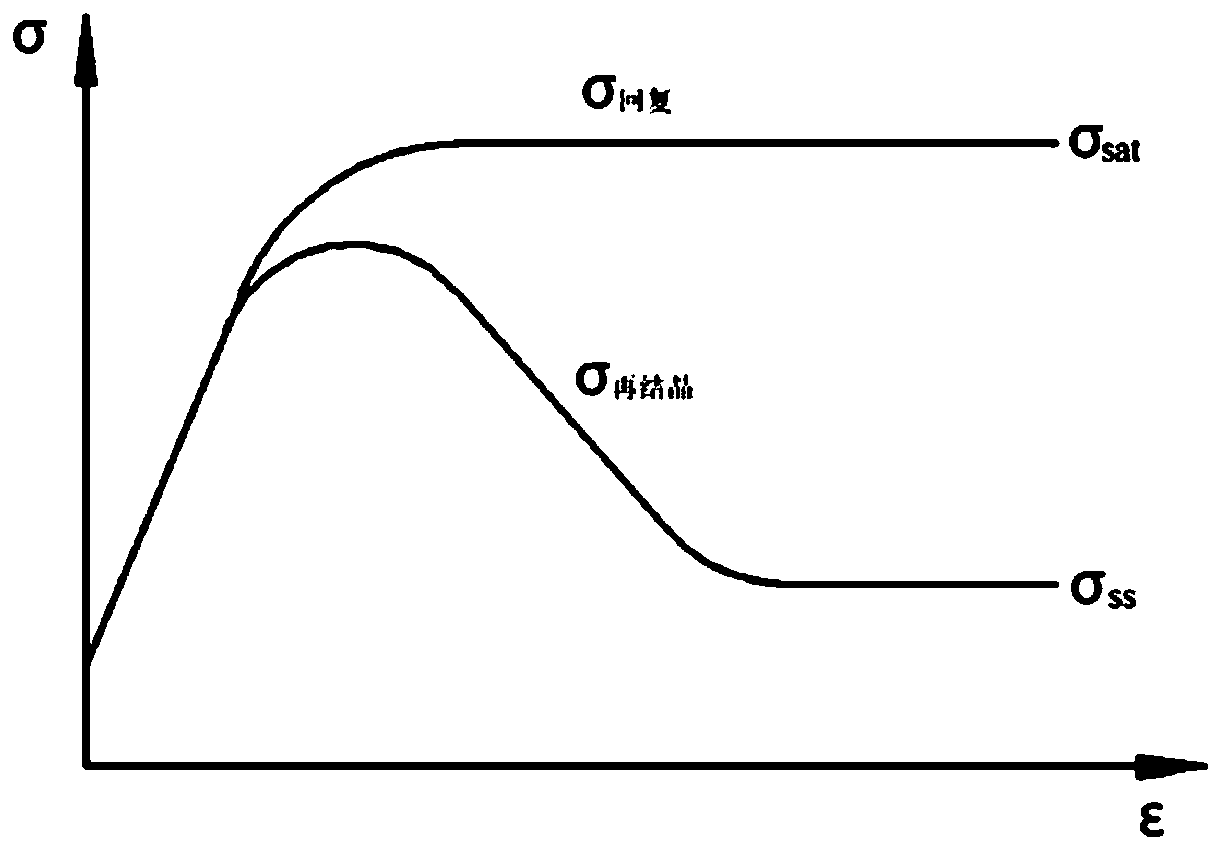

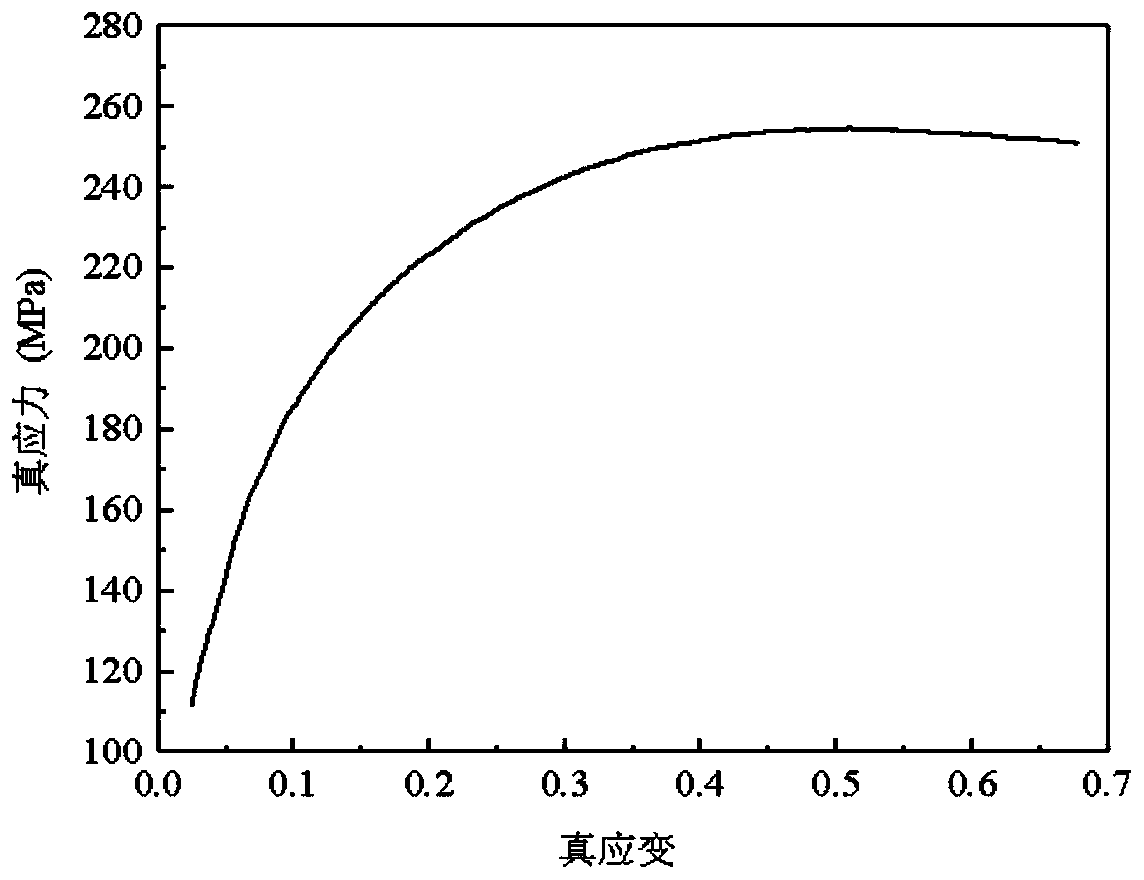

[0068] Step 1. Obtain the stress-strain curve of the material through experiments, such as figure 2 As shown; after the sample is deformed, it is immediately water-quenched to retain its deformed structure. The quenched structure is as follows image 3 As shown, the recrystallized grains are as Figure 4 As shown, then observe the metallographic structure inside the sample, and the measured recrystallization volume fraction is 28.1%;

[0069] Step 2. Determine the critical strain ε for dynamic recrystallization c , first, for specific deformation conditions (temperature and strain rate), use formula (1) to calculate the slope θ of the corresponding stress-strain curve everywhere;

[0070]

[0071] Then use θ as the ordinate and σ as the abscissa, draw the curve, ε c ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com