Production method of fine-grain high-strength GH4169 alloy by hot rolling

A technology of GH4169 and production method, which is applied in the field of hot rolling production of fine-grained high-strength superalloys, can solve the problems of unstable quality, low production efficiency, grain growth, etc., and achieves significant economic benefits, production cycle reduction, strength improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

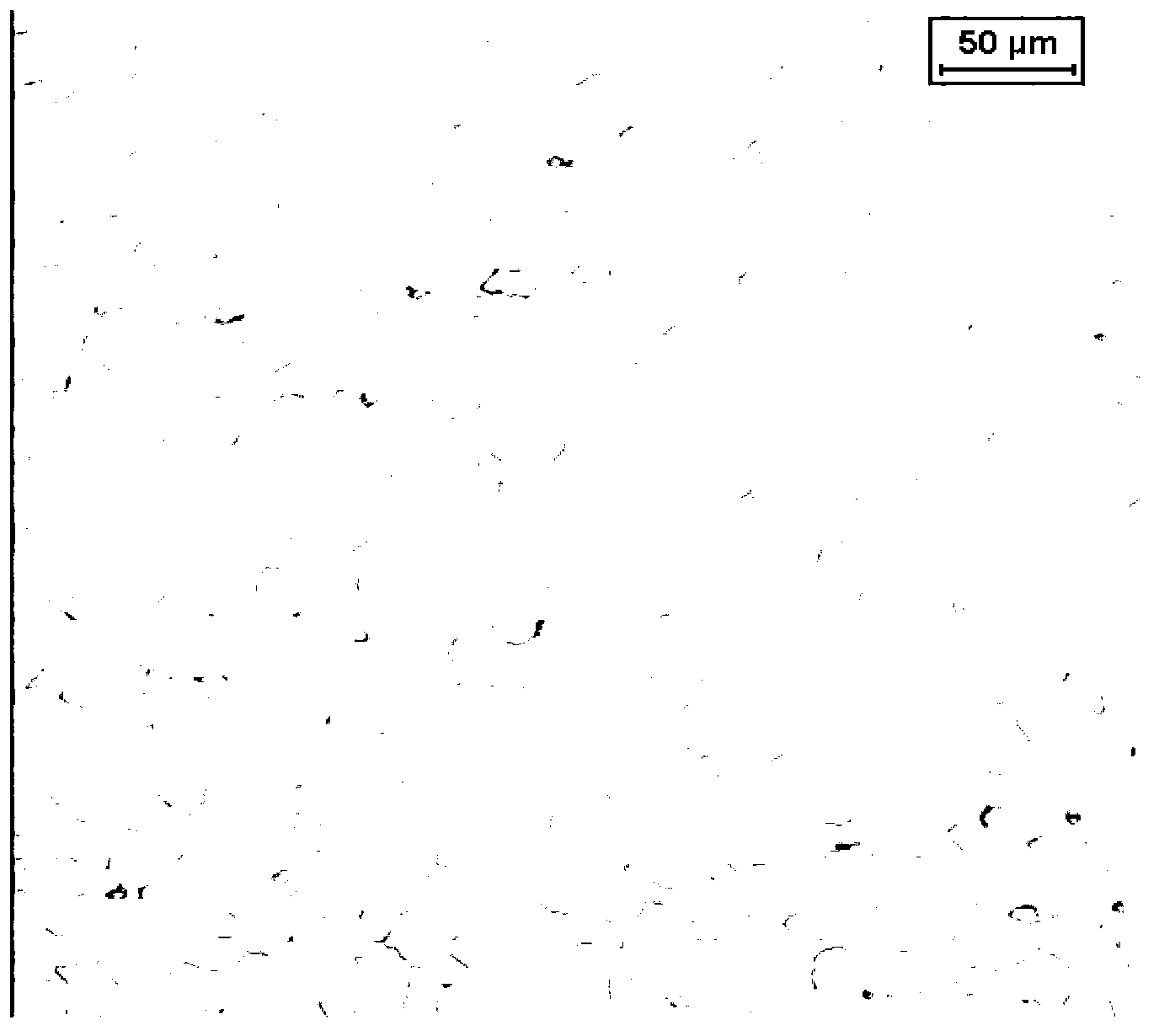

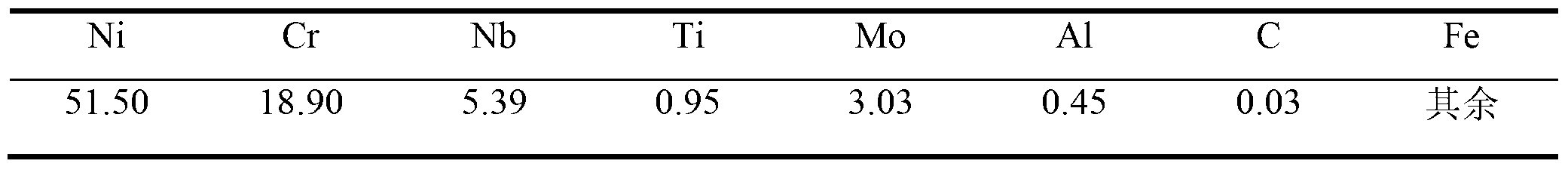

[0019] Taking the GH4169 round steel with a diameter of 23 mm as an example, the chemical composition of the alloy is shown in Table 1. The rough-rolled 80mm×80mm hot billet is subjected to temperature compensation heating at 1050±10°C×10min in a tunnel-type heating furnace. ·s -1 The entrance speed of the first stand enters the continuous rolling unit, and after 14 passes of continuous rolling, the grain size is as follows figure 1 It is about 13 μm, and after online solid solution + aging treatment, its performance is shown in Group 2 of Table 2. The data in Table 2 shows that the properties of GH4169 alloy rods in both air cooling (Group 1) and online solid solution cooling methods meet the standard "High-temperature Alloy Hot-Rolled Bars for Rotating Parts GB / T14993.1994". The tensile properties at room temperature, Brinell hardness and high temperature (650°C) tensile properties of the material in the online solid solution mode are significantly higher than the test resu...

Embodiment 2

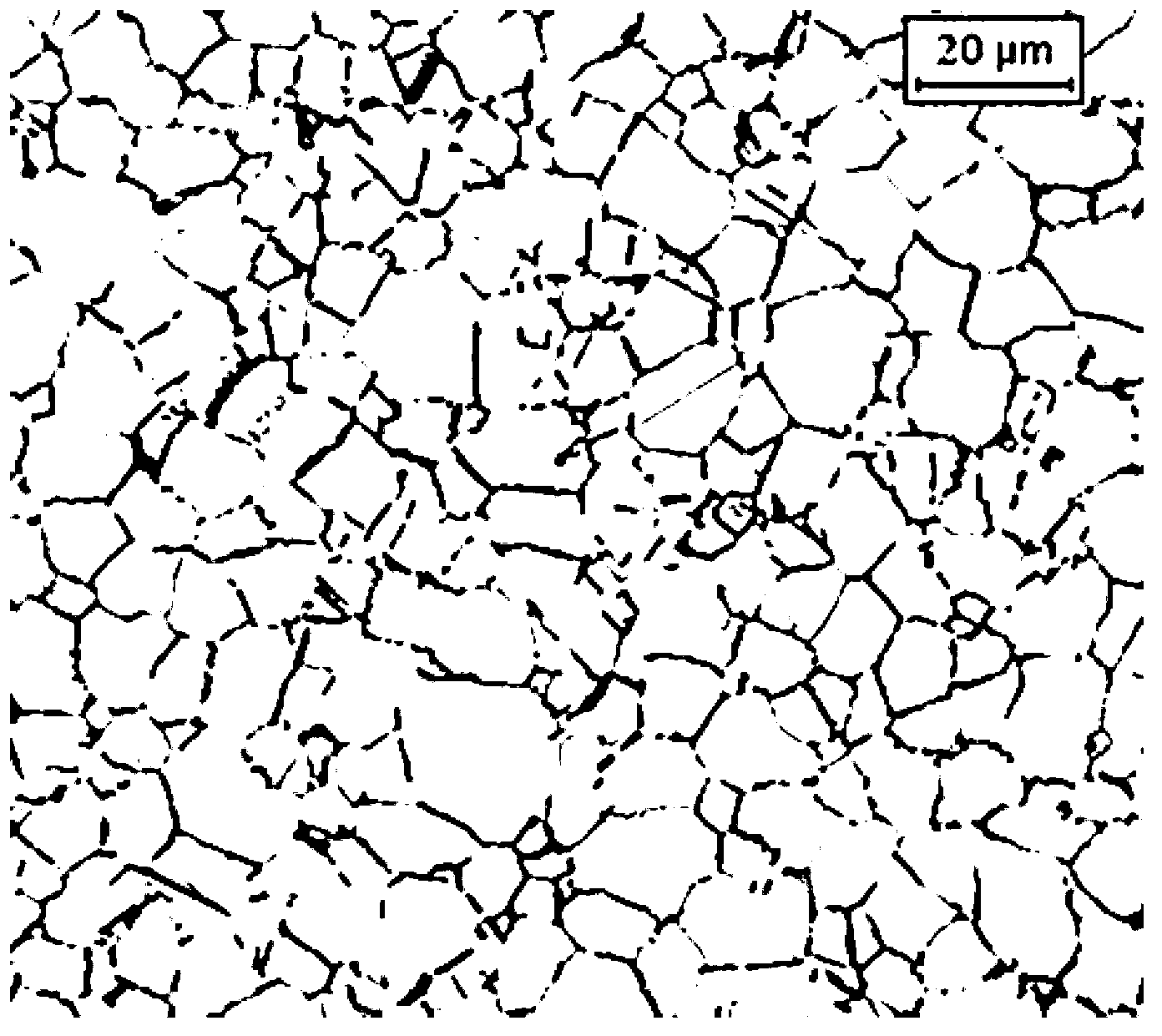

[0025] Taking the GH4169 round steel with a diameter of 45 mm as an example, the chemical composition of the alloy is shown in Table 1. The rough-rolled 80mm×80mm hot billet is heated by temperature compensation at 1050±10℃×10min in a tunnel-type heating furnace. ·s -1 The entrance speed of the first stand enters the continuous rolling unit, and after 6 passes of continuous rolling, the grain size is as follows figure 2 It is about 11 μm, and its properties are shown in Table 3 after online solid solution + aging treatment. The indicators in Table 3 are close to the indicators in Group 2 in Table 2, indicating that the performance of the product can be effectively controlled by using this technology; at the same time, due to the further refinement of the grain size (13μm→11μm), its various strength indicators It is slightly higher than the second group index in Table 2, indicating that the microstructure and properties of the product can be effectively adjusted by changing t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Elongation | aaaaa | aaaaa |

| Elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com