Cogging and forging method of TiAl alloy

A billet forging and alloying technology, which is applied in the field of TiAl alloy billet forging, can solve the problems of double bulging of forging cakes, short heat preservation time between passes, and insufficient use of billet forging, so as to achieve cost saving and uniform structure Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

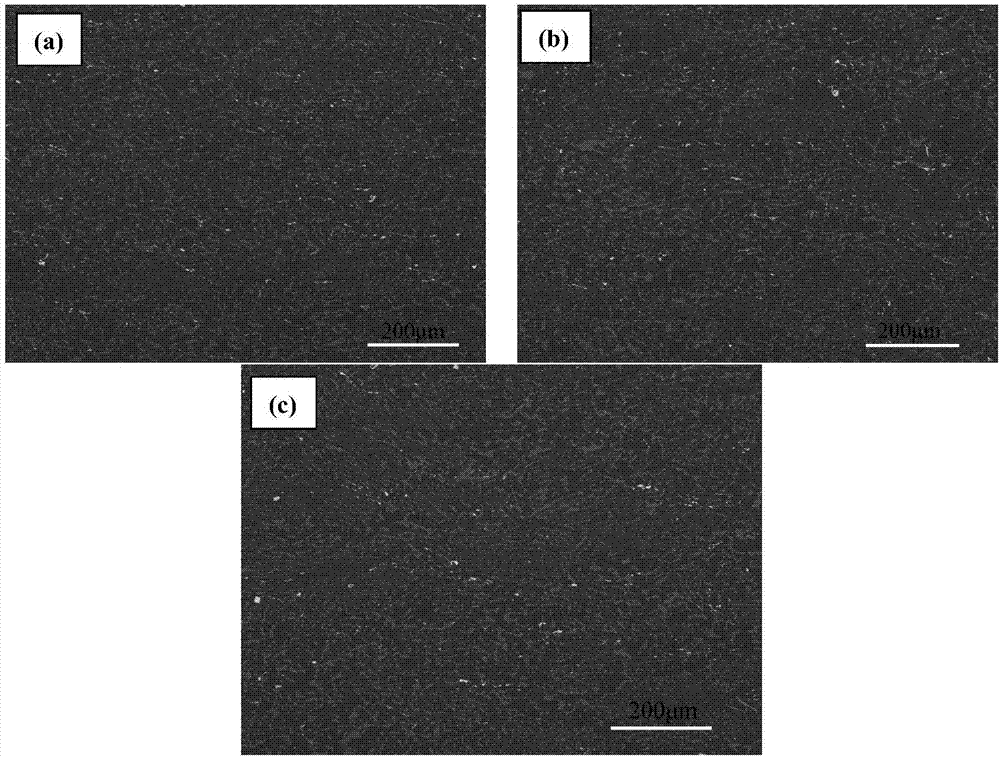

[0027] This embodiment is a method for billet forging of TiAl alloy.

[0028] The TiAl alloy described in this embodiment is a TNM alloy, its nominal composition is Ti-43.5Al-4Nb-1Mo-0.2B, the composition is atomic percentage, and the size of the ingot used is Φ50×120 mm.

[0029] The specific process described in this embodiment is as follows:

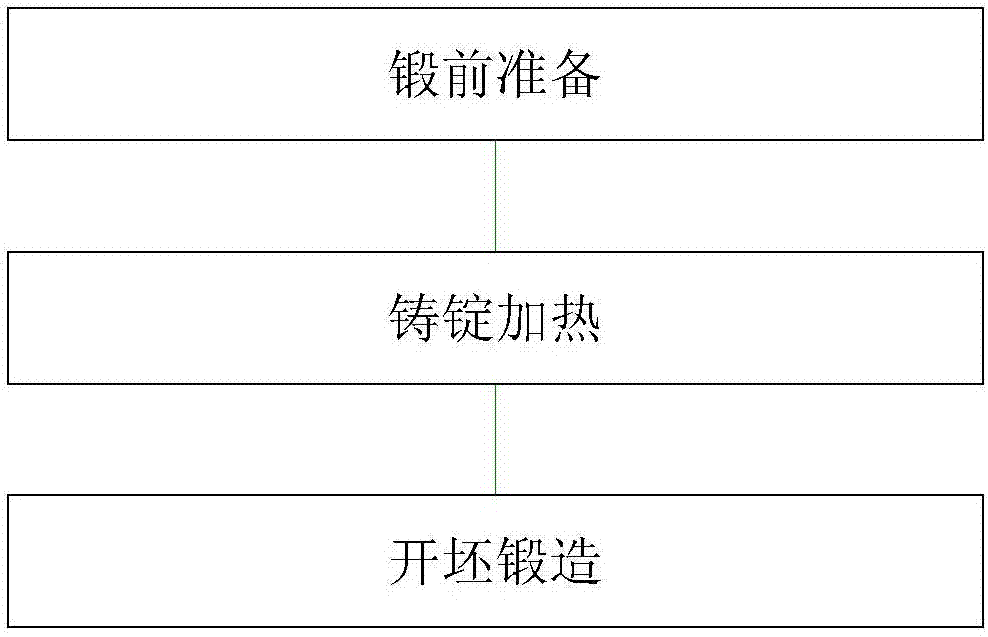

[0030] The first step is preparation before forging. The preparation before forging includes preparing an ingot and wrapping the ingot.

[0031] Process an ingot with a size of Φ50×120mm from the ingot after hot isostatic pressing to ensure that the surface quality of the ingot is good and free of defects. The ingot is covered, and there is a gap of 3mm between the assembled ingot and the covering, which is used to fill the insulation cotton; the material of the covering is stainless steel, and the thickness is 10mm. After filling the 3mm gap between the sheath and the ingot with thermal insulation cotton, the sheath is connected by ...

Embodiment 2

[0043] This embodiment is a method for billet forging of TiAl alloy.

[0044] The nominal composition of the TiAl alloy described in this embodiment is Ti-43.5Al-4Nb-1Mo-0.2B, the composition is atomic percentage, and the size of the ingot used is Φ50×120 mm.

[0045] The specific process described in this embodiment is as follows:

[0046] The first step is preparation before forging. The preparation before forging includes preparing an ingot and wrapping the ingot.

[0047] Process an ingot with a size of Φ50×120mm from the ingot after hot isostatic pressing to ensure that the surface quality of the ingot is good and free of defects. The ingot is covered, and there is a gap of 3mm between the assembled ingot and the covering, which is used to fill the insulation cotton; the material of the covering is stainless steel, and the thickness is 10mm. After filling the 3mm gap between the sheath and the ingot with thermal insulation cotton, the sheath is connected by argon arc w...

Embodiment 3

[0061] This embodiment is a method for billet forging of TiAl alloy.

[0062] The nominal composition of the TiAl alloy described in this implementation example is Ti-48Al-2Nb-2Cr, the composition is atomic percentage, and the size of the ingot used is Φ50×120mm.

[0063] The specific process described in this embodiment is as follows:

[0064] The first step is preparation before forging. The preparation before forging includes preparing an ingot and wrapping the ingot.

[0065] Process an ingot with a size of Φ50×120mm from the ingot after hot isostatic pressing to ensure that the surface quality of the ingot is good and free of defects. The ingot is covered, and there is a gap of 3mm between the assembled ingot and the covering, which is used to fill the insulation cotton; the material of the covering is stainless steel, and the thickness is 10mm. After filling the 3mm gap between the sheath and the ingot with thermal insulation cotton, the sheath is connected by argon a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com