Method of assistance of resistance heating in surface mechanical grinding to form gradient nanostructure

A surface mechanical grinding and resistance heating technology, applied in the direction of improving process efficiency, can solve the problems such as the inability to effectively eliminate the fatigue source of the surface layer of the metal workpiece and the shallow plastic deformation layer, and achieve the improvement of plasticity, easy temperature control, and improvement of surface quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

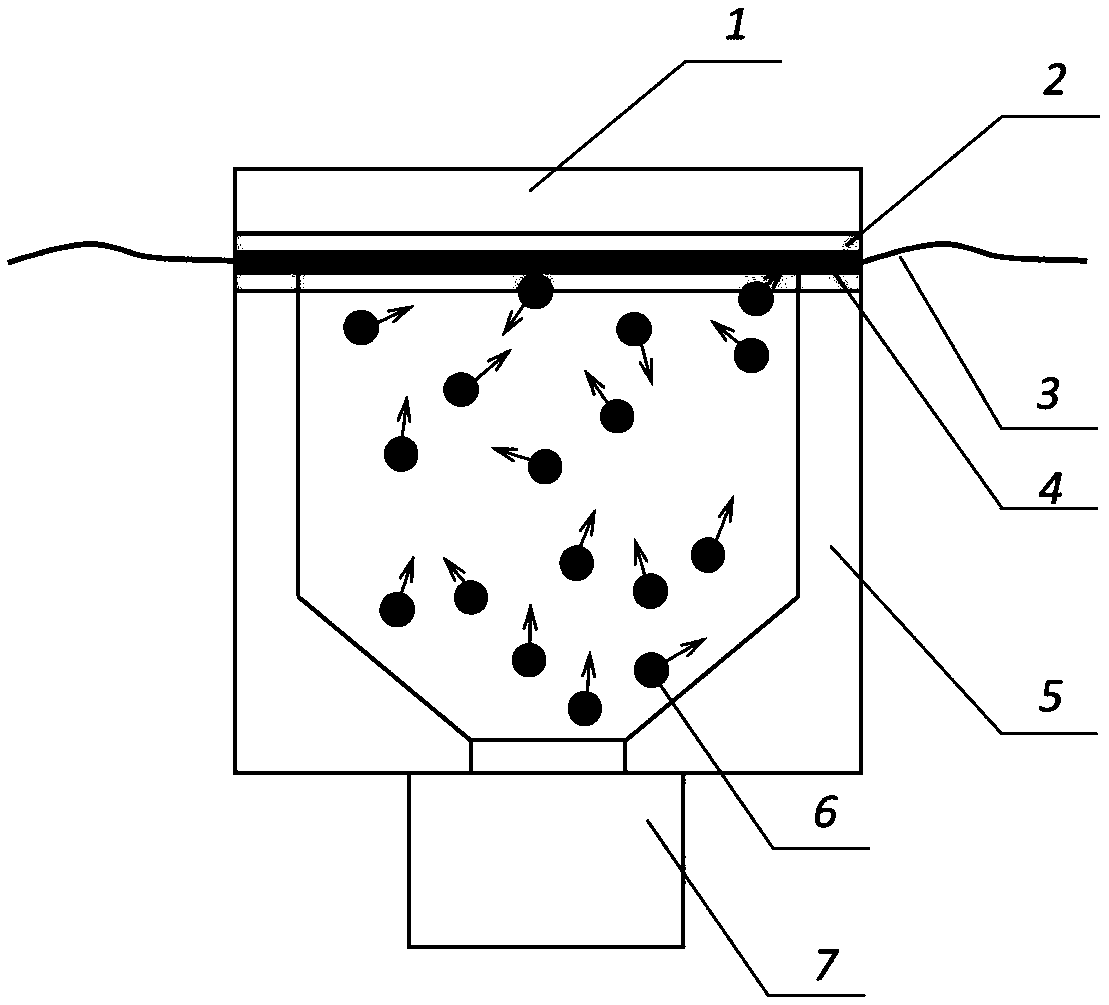

Method used

Image

Examples

Embodiment 1

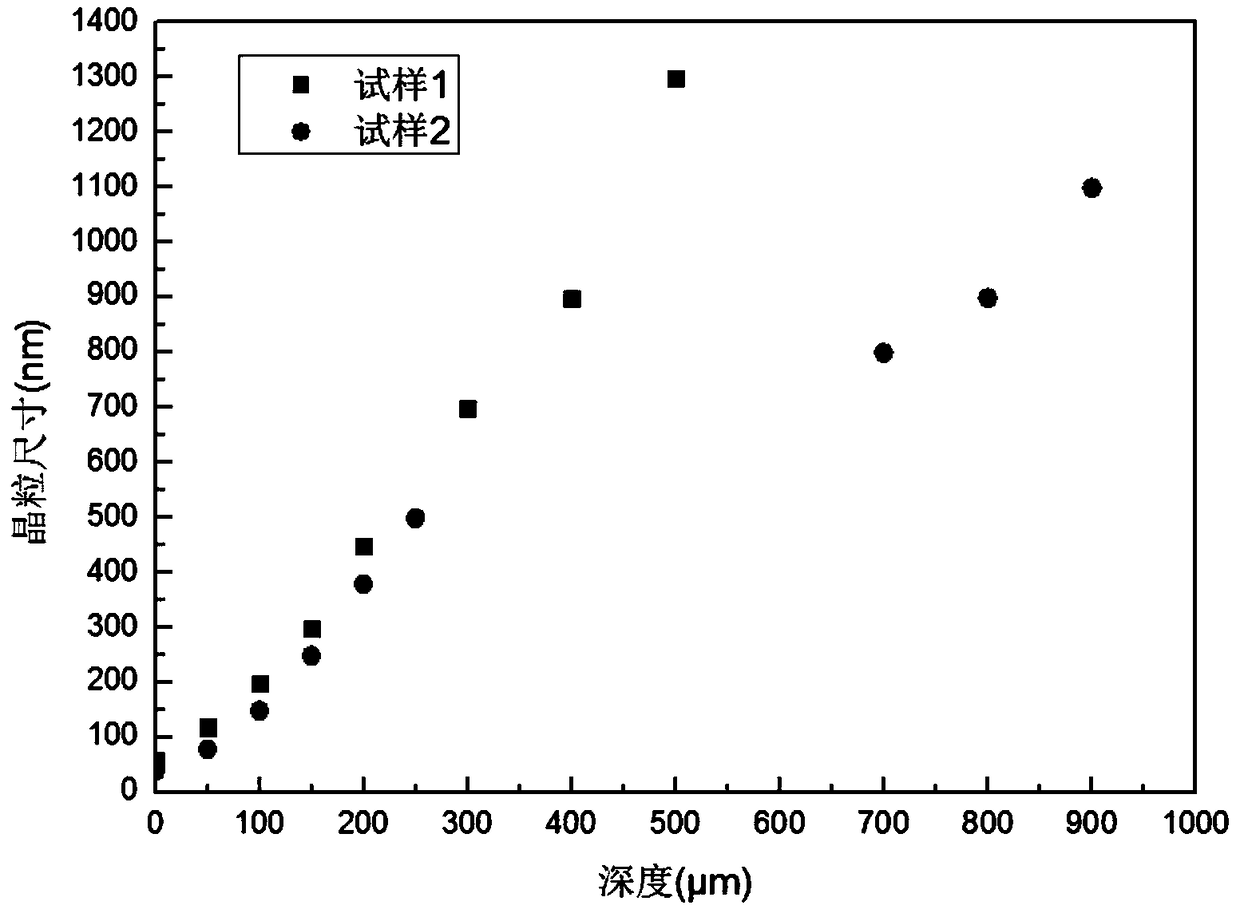

[0026] A kind of example that uses above-mentioned method to prepare 316L stainless steel surface layer gradient nanostructure, its steps are:

[0027] (1) Two 316L stainless steel plates with a thickness of 5mm were selected. Both plates were vacuum annealed at 900°C for 3 hours, and they were recorded as sample 1 and sample 2 respectively. Sample 1 was a comparative sample.

[0028] (2) Grind and polish the upper surfaces of the two samples in step (1) with 400#, 600#, 800#, 1000#, 1200#, 1500# and 2000# sandpaper in order to remove the oxidation on the surface of the metal workpiece Layer, and then ultrasonically cleaned with deionized water to remove abrasive debris and dirt on the surface of the metal workpiece.

[0029] (3) Perform surface mechanical grinding treatment on sample 1, wherein the surface mechanical grinding treatment parameters are as follows: the diameter of the steel shot is 8 mm, the roughness of the steel shot is Ra 1.6, the vibration frequency is 50 Hz...

Embodiment 2

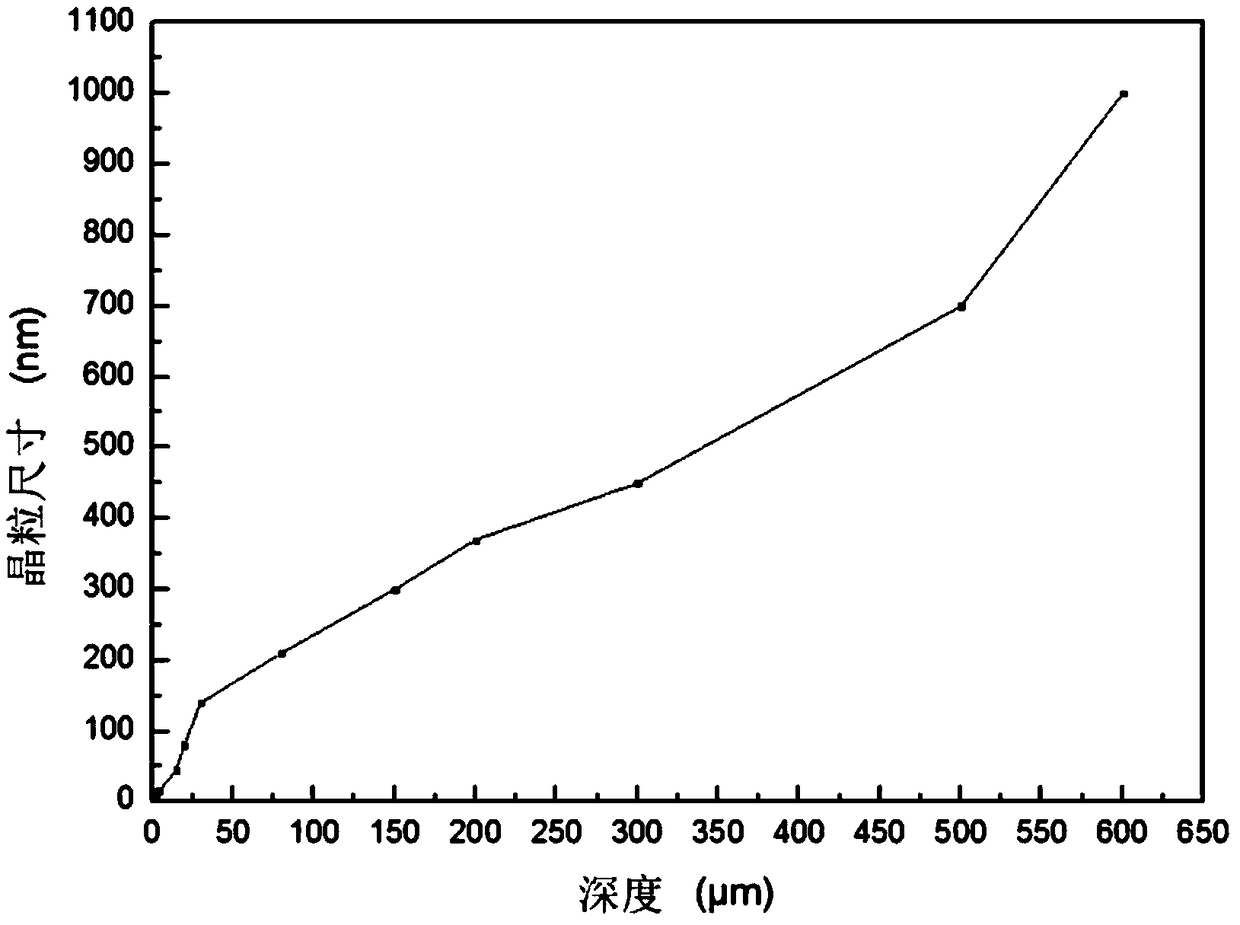

[0033] A kind of example that uses above-mentioned method to prepare industrial pure copper surface layer gradient nanostructure, its steps are:

[0034] (1) Select two industrial pure copper plates with a thickness of 5mm (purity>99.9wt.%). After the two plates are vacuum annealed at 700°C for 2 hours, they are respectively recorded as sample 3 and sample 4. Among them, the sample 3 is a comparative sample.

[0035] (2) Grind and polish the upper surfaces of the two samples in step (1) with 400#, 600#, 800#, 1000#, 1200#, 1500# and 2000# sandpaper in order to remove the oxidation on the surface of the metal workpiece Layer, and then ultrasonically cleaned with deionized water to remove abrasive debris and dirt on the surface of the metal workpiece.

[0036] (3) Perform surface mechanical grinding treatment on sample 3, wherein the surface mechanical grinding treatment parameters are as follows: the diameter of the steel shot is 8 mm, the roughness of the steel shot is Ra 1.6...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com