Beneficiation method for stepped recovery and segmented tailing discarding of low-grade chromite

A technology of cascade recovery and beneficiation method, applied in the direction of solid separation, etc., can solve the problems of small processing capacity of equipment, large amount of fine tailings, complicated equipment operation, etc. high yield effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

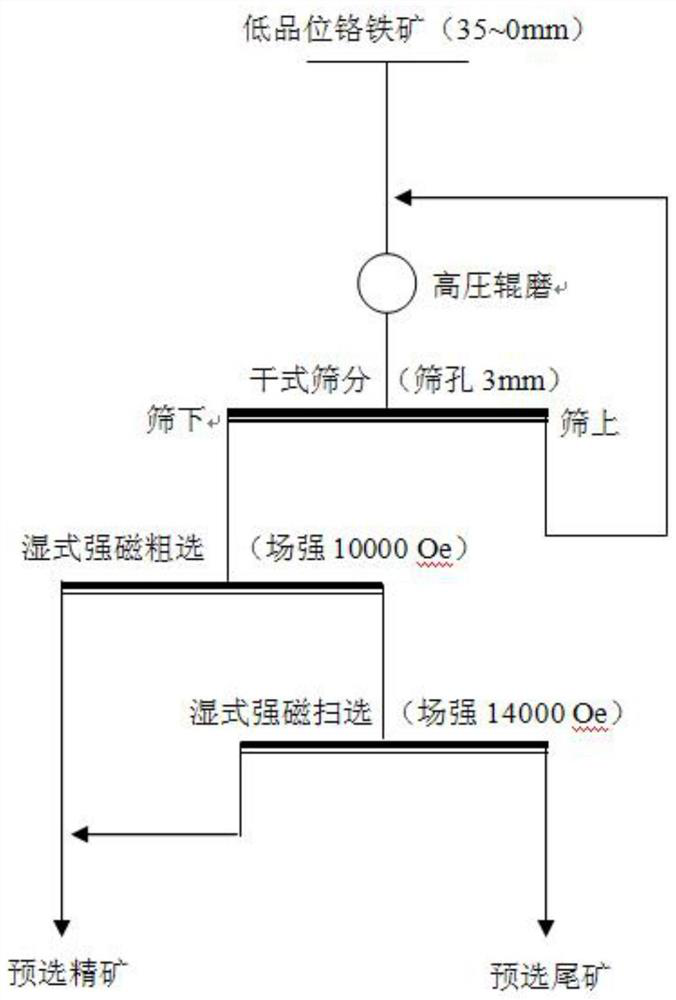

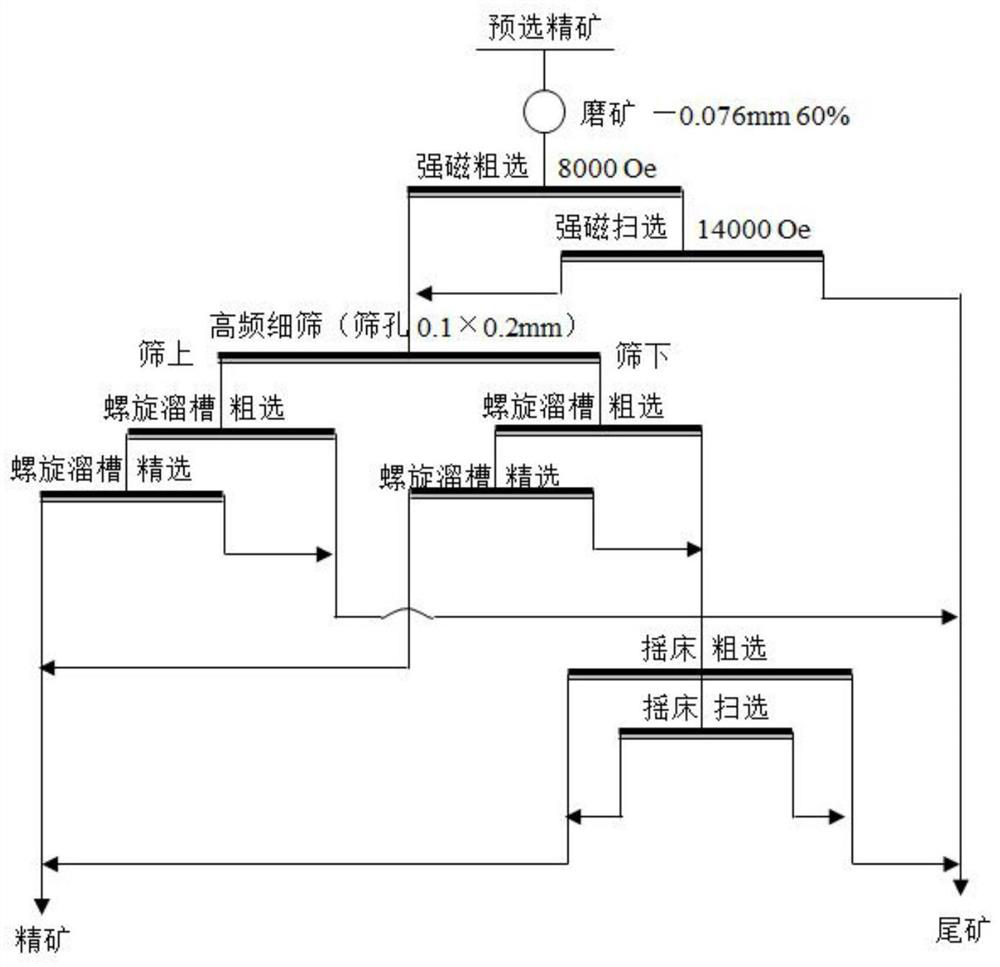

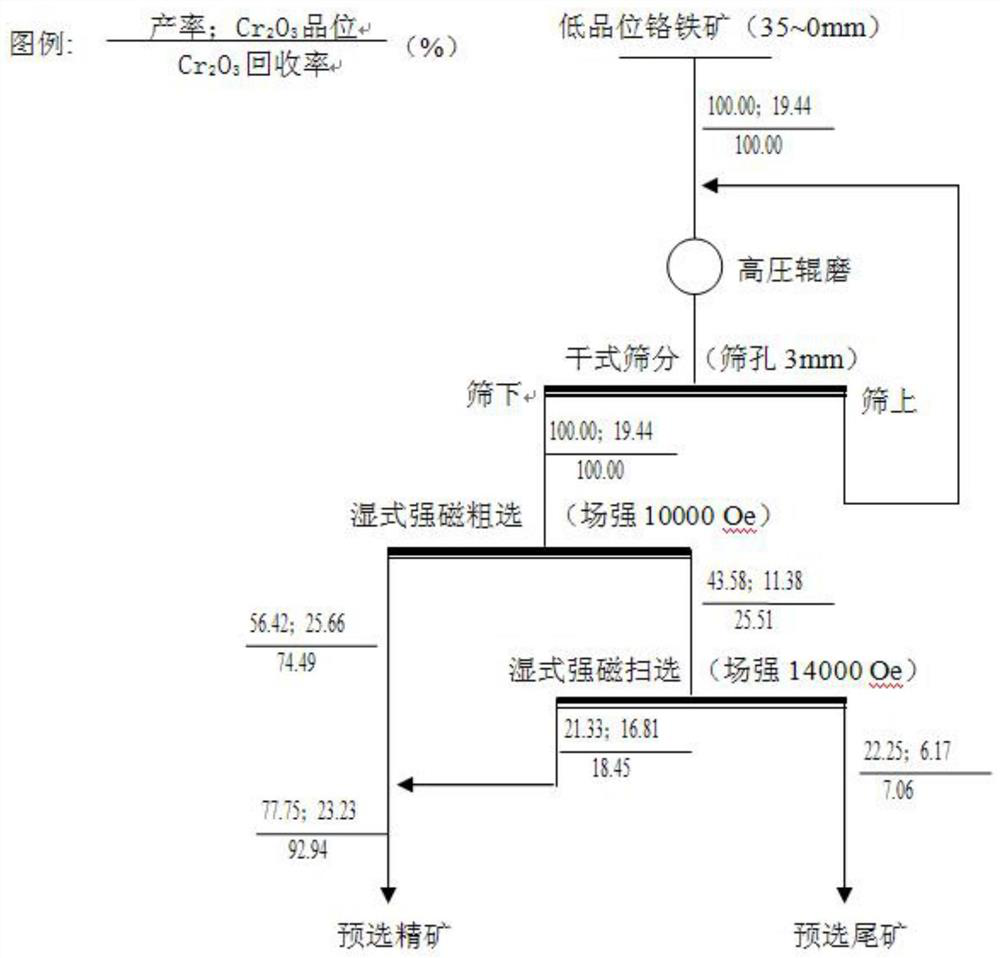

Method used

Image

Examples

Embodiment Construction

[0029] To describe the present invention, a beneficiation method of cascaded recovery of low-grade chromite and segmented tailings of the present invention will be further described in detail below in conjunction with the accompanying drawings and examples.

[0030] The object of treatment in this example is a certain chromite ore in Tibet. The results of its chemical multi-element analysis and chromium phase analysis are shown in Table 1 and Table 2.

[0031] Table 1 Chemical multi-element analysis results of a chromite ore (%)

[0032] element name Cr 2 o 3

Fe 2 o 3

CaO MgO SiO 2

al 2 o 3

content 19.44 9.28 0.738 35.32 26.55 3.92 element name TiO 2

V 2 o 5

MnO K 2 o

Na 2 o

NiO content 0.069 0.045 0.133 0.016 <0.005

0.361 element name CuO ZnO S P content 0.034 0.015 0.017 0.008

[0033] Table 2 Certain chromite ore chromium phase analysis resu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com