High-strength high-toughness weldable in-situ nano-reinforced rare earth aluminum alloy and preparation method thereof

An aluminum alloy, in-situ technology, applied in the field of aluminum alloy materials, can solve the problems of composite material performance impact, rare earth strengthening effect limited, material performance deterioration, etc., to improve wetting and bonding strength, improve weldability, and uniform distribution Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

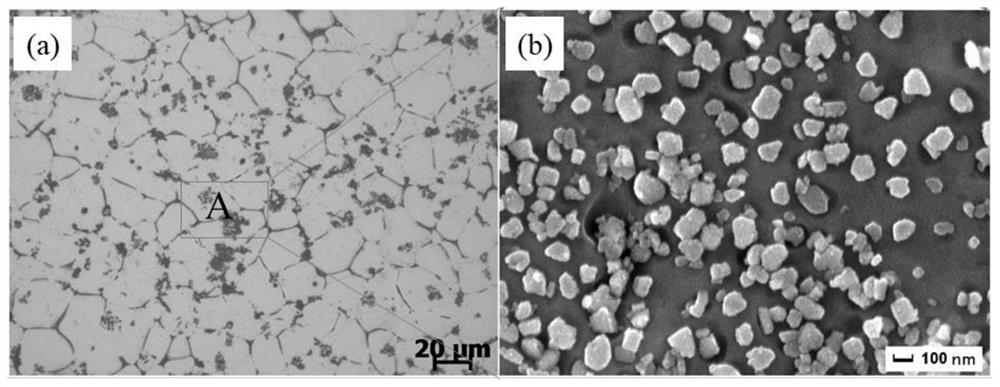

Image

Examples

Embodiment 1

[0036] The chemical composition of the rare earth aluminum alloy is (mass percentage): Zn: 6.02, Mg: 2.59, Mn: 0.76, Cr: 0.11, Cu: 0.23, Zr: 1.80, Ti: 1.82, B: 0.80, O: 0.20, Er: 0.10, Sc: 0.12, Y: 0.10, and the rest are Al.

[0037] Weigh a certain amount of K 2 ZrF 6 、K 2 TiF 6 、KBF 4 and Na 2 B 4 o 7 , after dehydration at 200°C for 3 hours, mix and grind evenly; put pure aluminum in a crucible, use an induction coil to heat and melt, keep the temperature of the aluminum liquid at 850°C, wrap the reactant powder after mixing and grinding with aluminum foil and use a bell jar Press into the molten aluminum to fully react; turn on the electromagnetic control device and ultrasonic, the pulse width is 500μs, the frequency is 10Hz, the peak intensity of the pulsed magnetic field is 1T, the ultrasonic power is 5kW, the ultrasonic treatment is 10min, the interval is 2min, the reaction is 30min, and the temperature of the melt is lowered. To 750°C, add pure Cu, pure Zn, Al-Mn...

Embodiment 2

[0039] Zn: 5.03, Mg: 2.06, Mn: 0.71, Cr: 0.13, Cu: 0.25, Zr: 2.30, Ti: 2.26, B: 1.90, O: 0.45, Er: 0.2, Sc: 0.2, Y: 0.21, and the rest Al.

[0040] Weigh a certain amount of K 2 ZrF 6 、K 2 TiF 6 、KBF 4 and Na 2 B 4 o 7 , after dehydration at 200°C for 3 hours, mix and grind evenly; put pure aluminum in a crucible, use an induction coil to heat and melt, keep the temperature of the aluminum liquid at 870°C, wrap the reactant powder after mixing and grinding with aluminum foil and use a bell jar Press into the molten aluminum to fully react; turn on the electromagnetic and ultrasonic control device, the pulse width is 1ms, the frequency is 12Hz, the peak intensity of the pulsed magnetic field is 3T, the ultrasonic power is 6kw, the ultrasonic treatment is 10min, the interval is 2min, the reaction is 25min, and the melt temperature drops to 760°C, add pure Cu, pure Zn, Al-Mn, Al-Cr, Al-Zr, Al-Sc, Al-Er, Al-Y. React for 10 minutes, remove slag after the reaction, refine a...

Embodiment 3

[0042] Rare earth aluminum alloy composition: Zn: 6.99, Mg: 2.98, Mn: 0.74, Cr: 0.15, Cu: 0.28, Zr: 3.11, Ti: 3.23, B: 2.45, O: 0.53, Er: 0.3, Sc: 0.3 , Y: 0.3, the rest is Al.

[0043] Weigh a certain amount of K 2 ZrF 6 、K 2 TiF 6 、KBF 4 and Na 2 B 4 o 7 , after dehydration at 200°C for 3 hours, mix and grind evenly; put pure aluminum in a crucible, use an induction coil to heat and melt, keep the temperature of the aluminum liquid at 890°C, wrap the reactant powder after mixing and grinding with aluminum foil and use a bell jar Press into the molten aluminum to fully react; turn on the electromagnetic and ultrasonic control device, the pulse width is 5ms, the frequency is 15Hz, the peak intensity of the pulsed magnetic field is 5T, the ultrasonic power is 10kW, the ultrasonic treatment is 10min, the interval is 2min, the reaction is 20min, and the temperature of the melt is lowered. To 770 ℃, add pure Cu, pure Zn, Al-Mn, Al-Cr, Al-Zr, Al-Sc, Al-Er, Al-Y. React for ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com