Patents

Literature

58results about How to "Make the transition" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

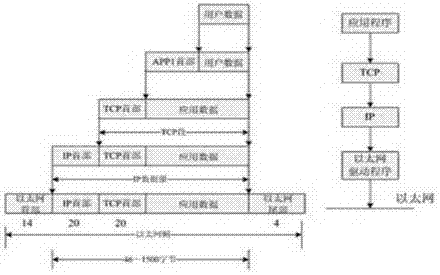

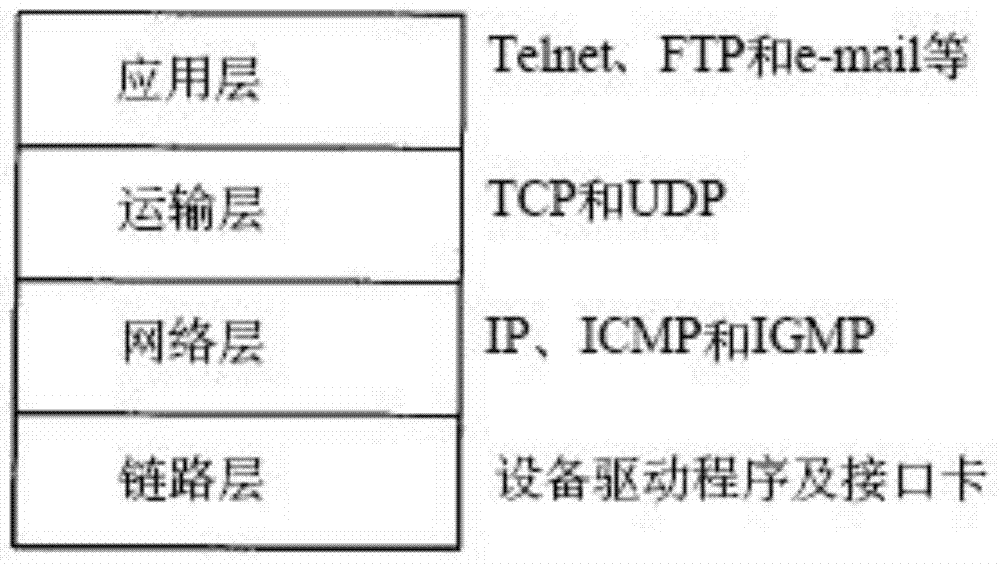

Ethernet IP message packaging method based on SDN and network isolation and DHCP implementing method based on SDN

ActiveCN104010049AImprove utilization efficiencySimplify the processData switching networksTransmission mediumMAC address

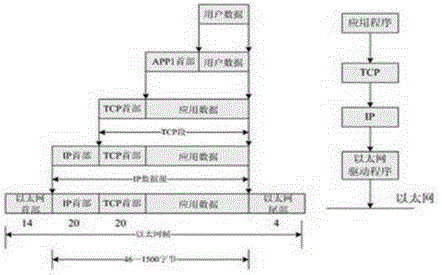

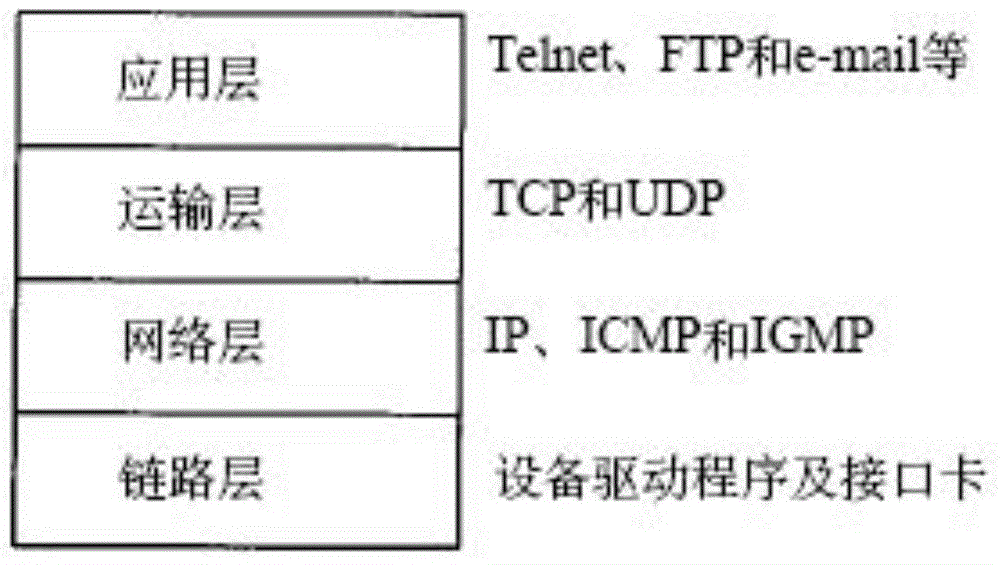

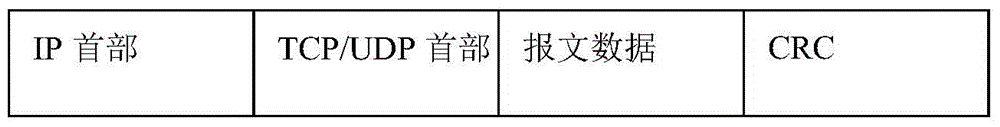

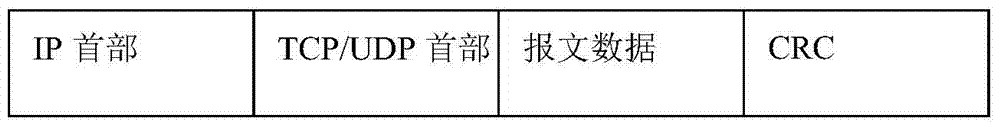

The invention provides an Ethernet IP message packaging method based on the SDN and a network isolation and DHCP implementing method based on the SDN. The technical problems that due to message layer two head packaging introduction, the transfer process is complex and the transmission efficiency is reduced are solved. The methods include the steps that firstly, an equipment physical layer obtains a physical signal from a transmission medium according to a frame gap and a guide frame, converts the physical signal into a bit and transfers the bit to a data link layer; secondly, the data link layer carries out prior processing work besides MAC address recognition and addressing; thirdly, a protocol stack recognition message is analyzed; fourthly, after being transferred out through a router, the message is transferred to the data link layer for carrying out other processing procedures besides Ethernet packaging and MAC addressing, and the message is sent to the physical layer to be processed according to the format of the message header; fifthly, the physical layer converts the bit of the data frame of the message into an optoelectronic signal in a prior mode and forwards the optoelectronic signal out.

Owner:EAYUN INC

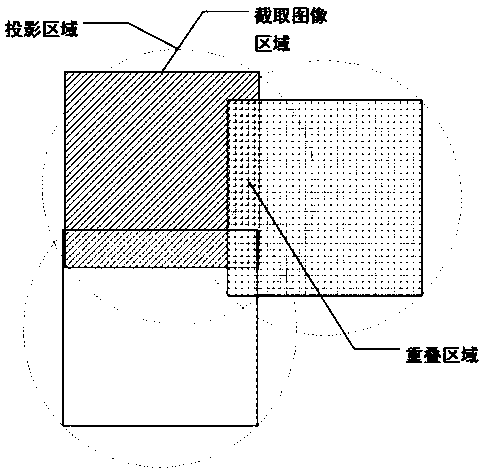

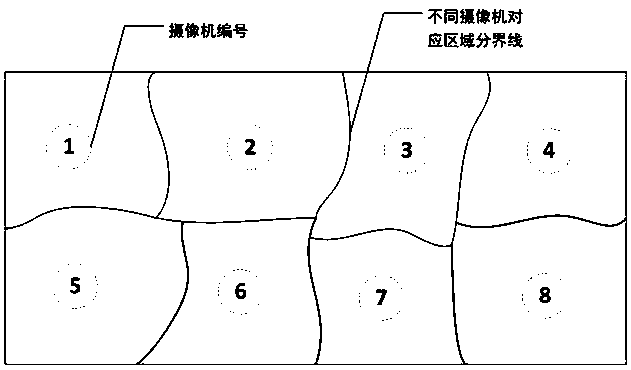

Panoramic monitoring system

ActiveCN109348119AMake the transitionRealize switchingTelevision system detailsPicture reproducers using projection devicesMonitoring systemField of view

The invention discloses a panoramic monitoring system. Some areas are selected from images of multiple panoramic cameras for spliced imaging, so as to form a large-scene global panoramic monitor graph, so that large-scene unified images are monitored in real time; a corresponding area is selected from the panoramic monitor image, so as to rapidly enter a specific corresponding camera to check panoramic image in a corresponding position; further, cameras show neighboring associated cameras mutually, so that vision fields of associated cameras can be transited and switched, and a 3D roaming effect in a real-time scene is realized. The system enables a user to browse a large scene without dead zones.

Owner:成都易瞳科技有限公司

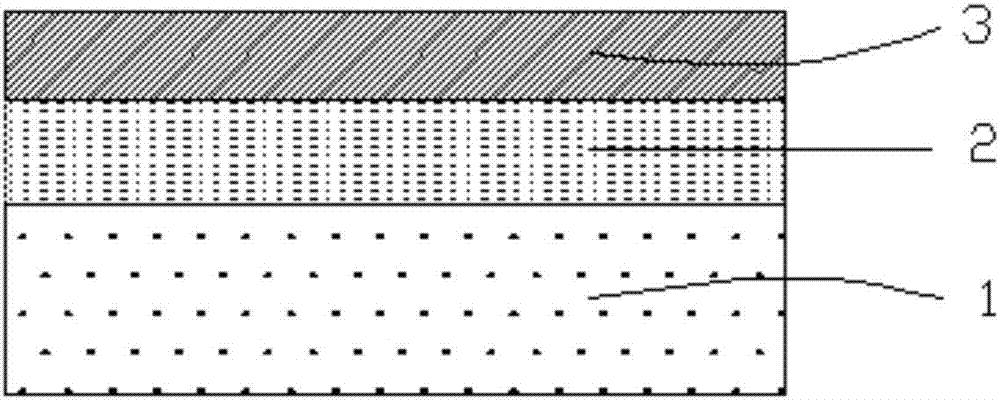

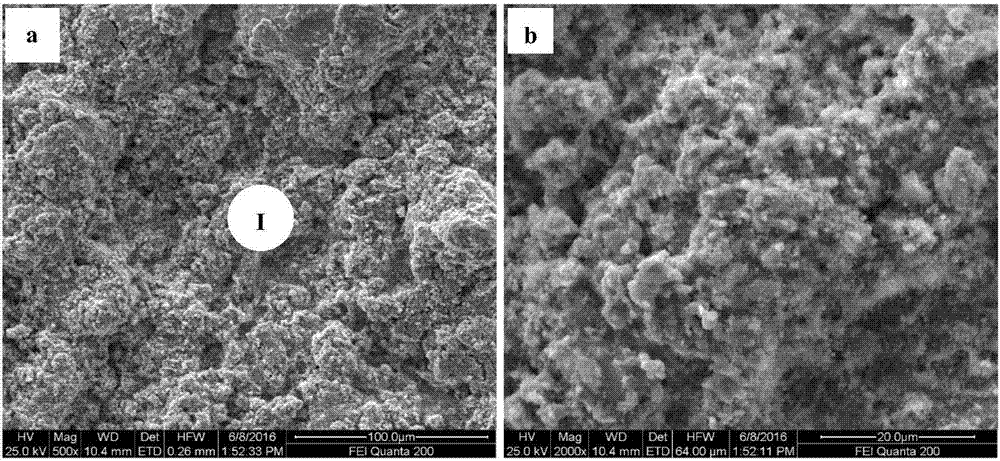

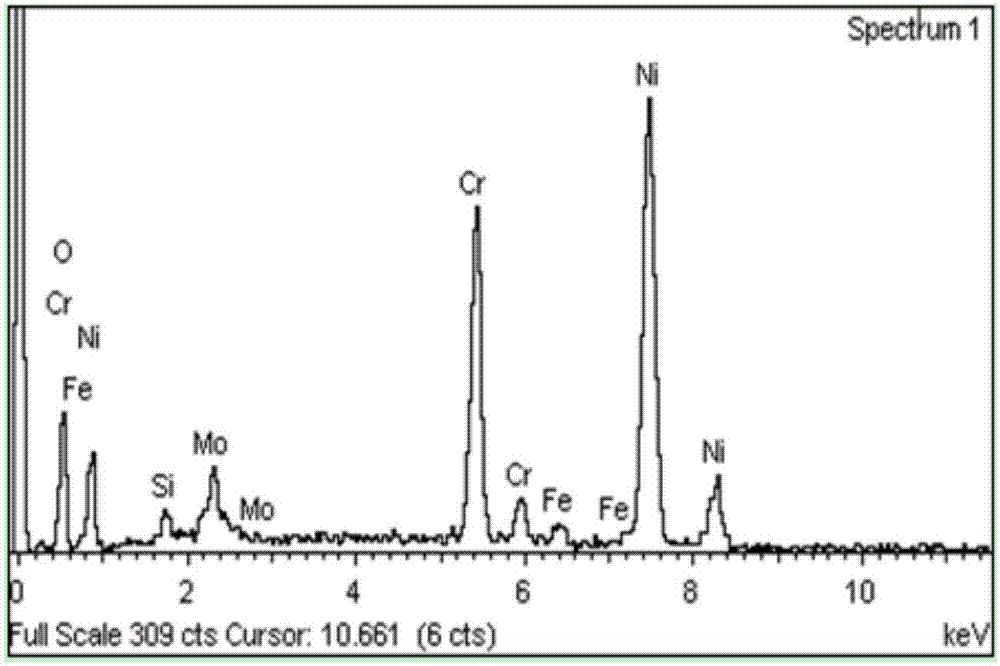

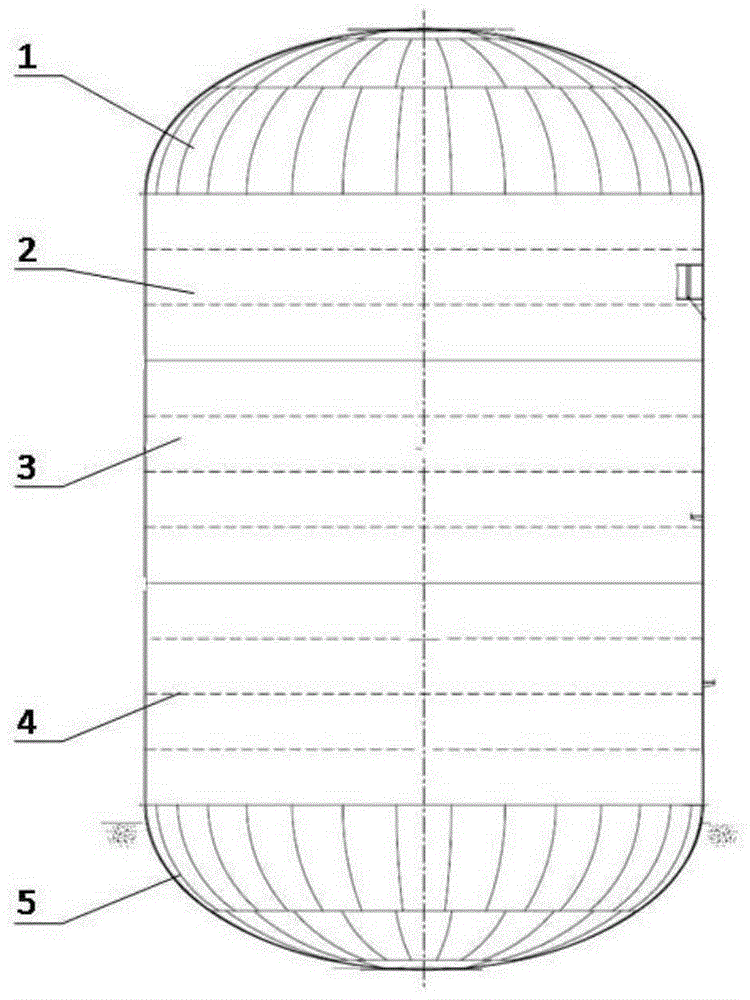

High-temperature-corrosion-resistant alloy coating of boiler heating surface and preparation method thereof

ActiveCN107034427AReduce porosityUniform and dense surfaceMolten spray coatingPorosityThermal spraying

The invention discloses a high-temperature-corrosion-resistant alloy coating of a boiler heating surface and a preparation method of the high-temperature-corrosion-resistant alloy coating of the boiler heating surface. The high-temperature-corrosion-resistant alloy coating comprises a NiCrAlY alloy priming coating and an Incone1625 / NiCr alloy finishing coating. The preparation method of the high-temperature-corrosion-resistant alloy coating comprises the steps that (1) Incone1625 alloy powder and NiCr alloy powder are evenly mixed according to a ratio, and spherical composite alloy powder is prepared and dried and stands for use; (2) the surface of a matrix is cleaned and roughened; (3) the surface of the matrix is coated with NiCrAlY alloy powder through a thermal spraying technology, so that the priming layer is formed; (4) the priming layer is coated with the spherical composite alloy powder through the thermal spraying technology, so that the finishing layer is formed; and (5) cooling is conducted, and then the high-temperature-corrosion-resistant alloy coating is obtained. The high-temperature-corrosion-resistant alloy coating prepared through the preparation method has the advantages of being low in porosity, uniform and dense in surface and good in high-temperature corrosion resistance, achieving that all the layers are tightly combined and the like, the service life of the boiler can be prolonged, and cost can be reduced.

Owner:GUANGZHOU SPECIAL PRESSURE EQUIP INSPECTION & RES INST

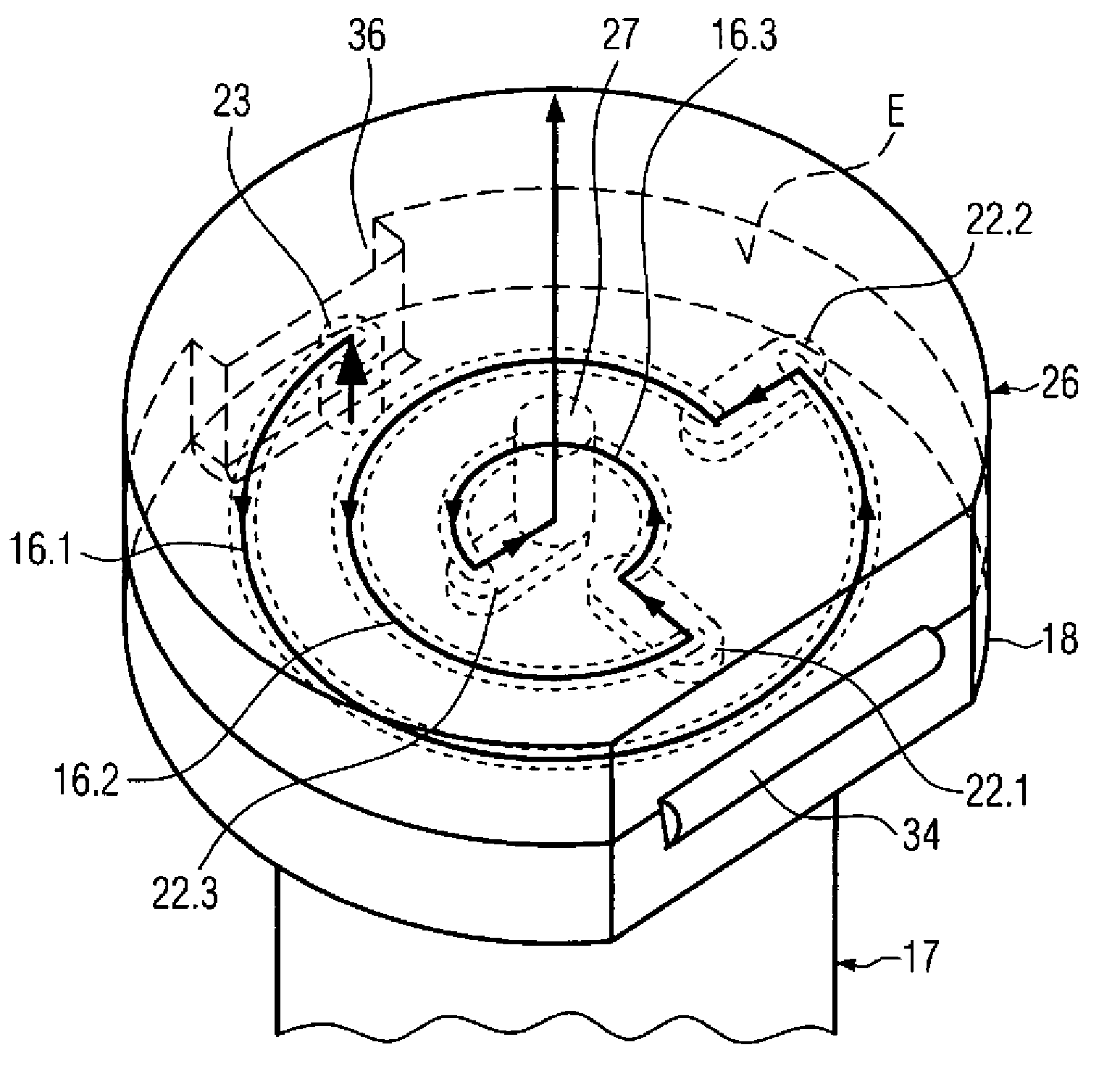

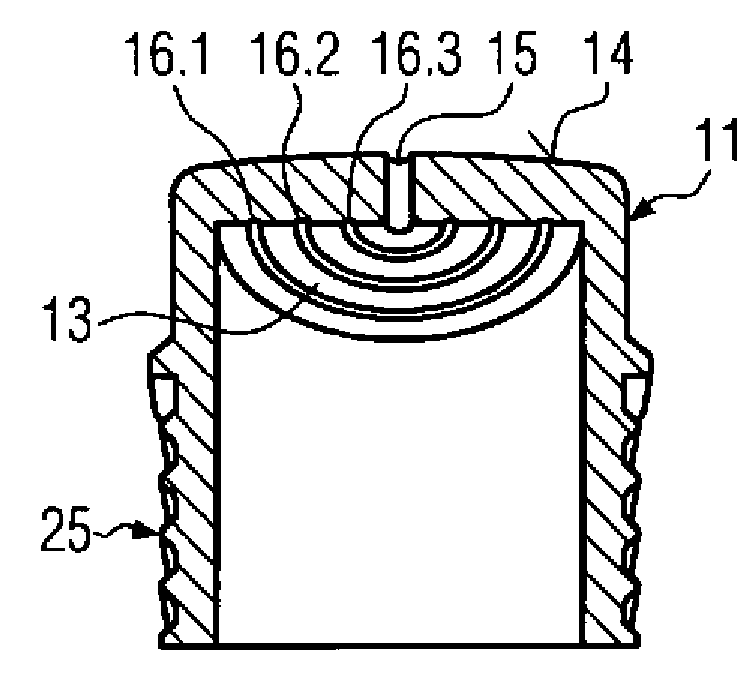

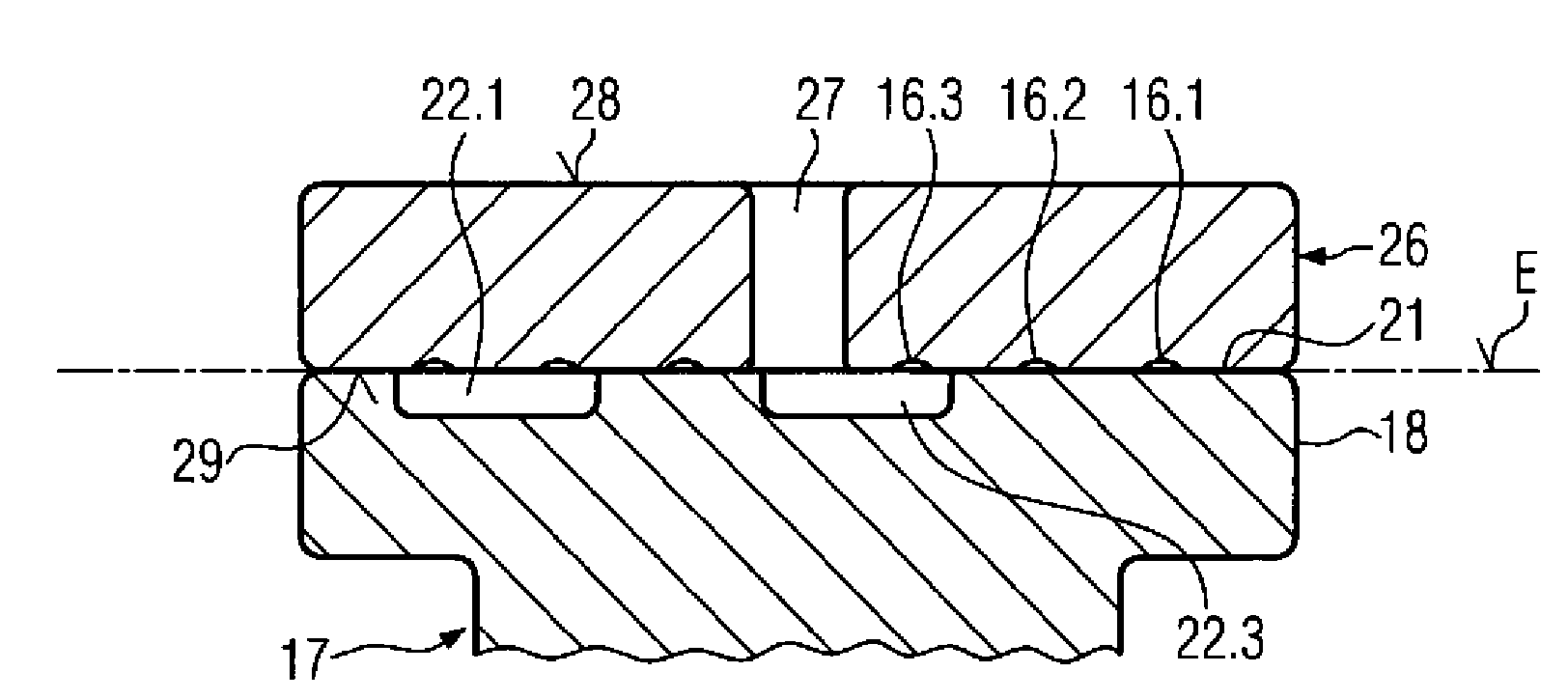

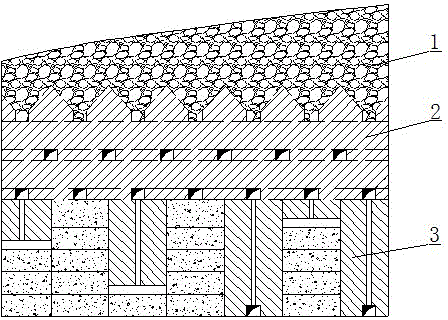

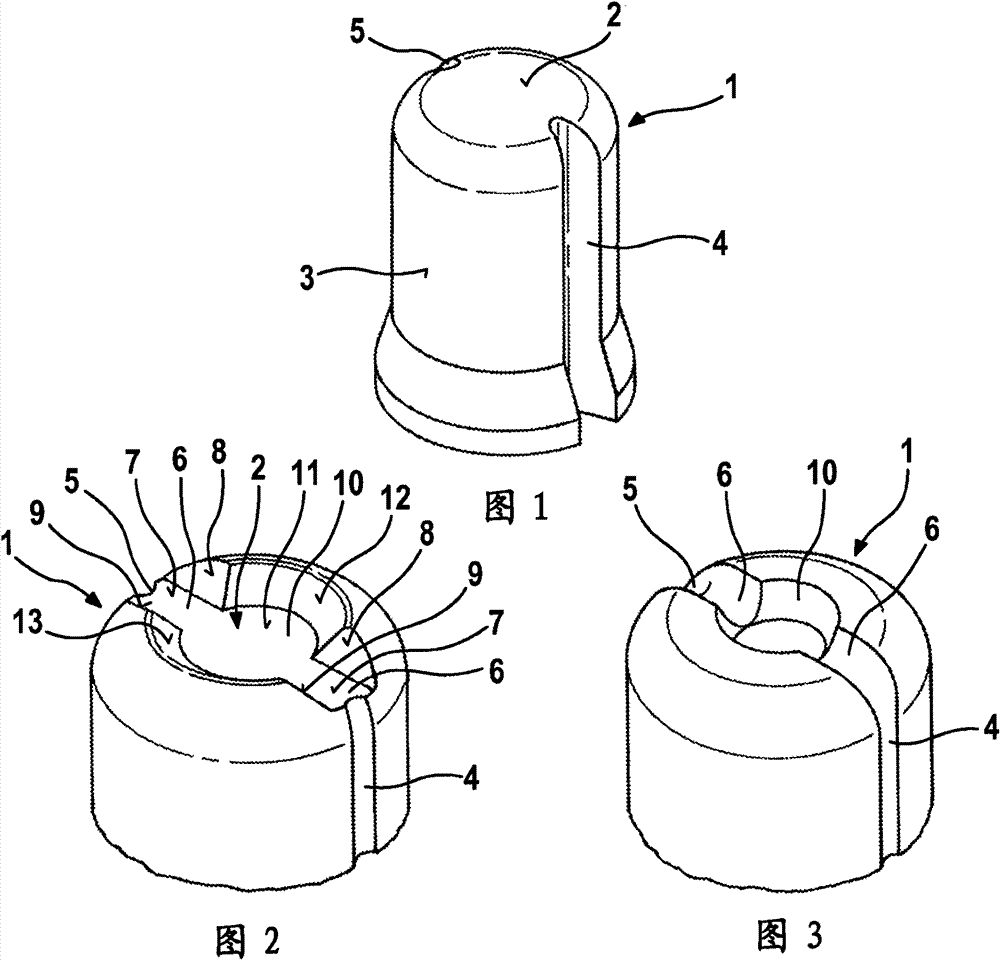

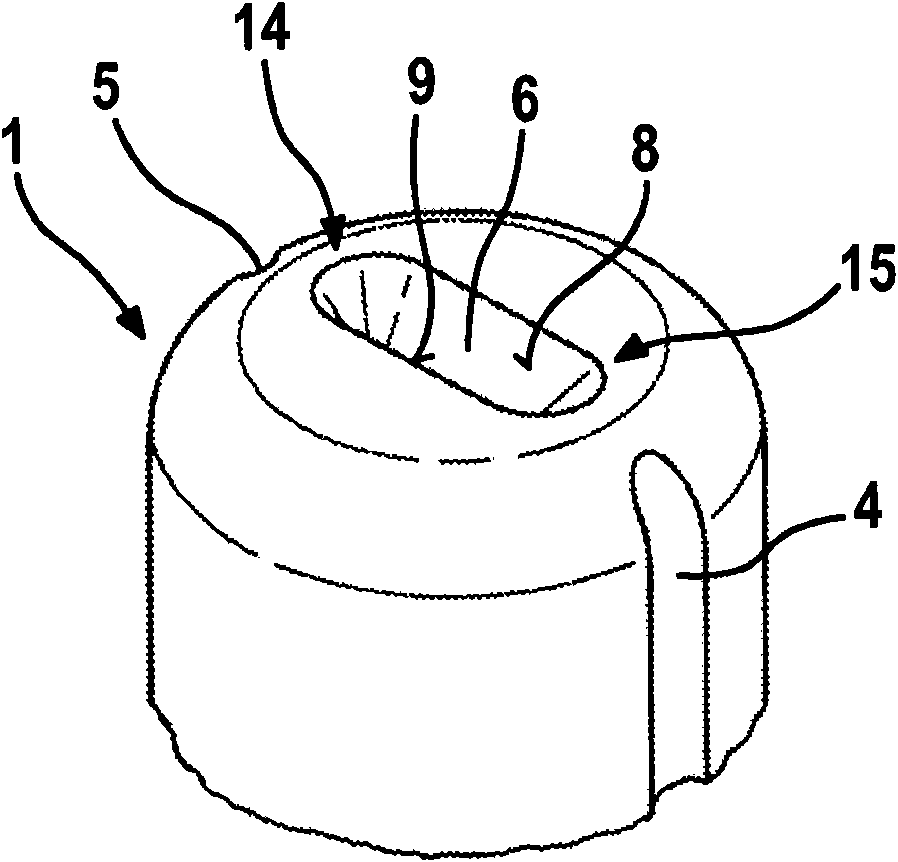

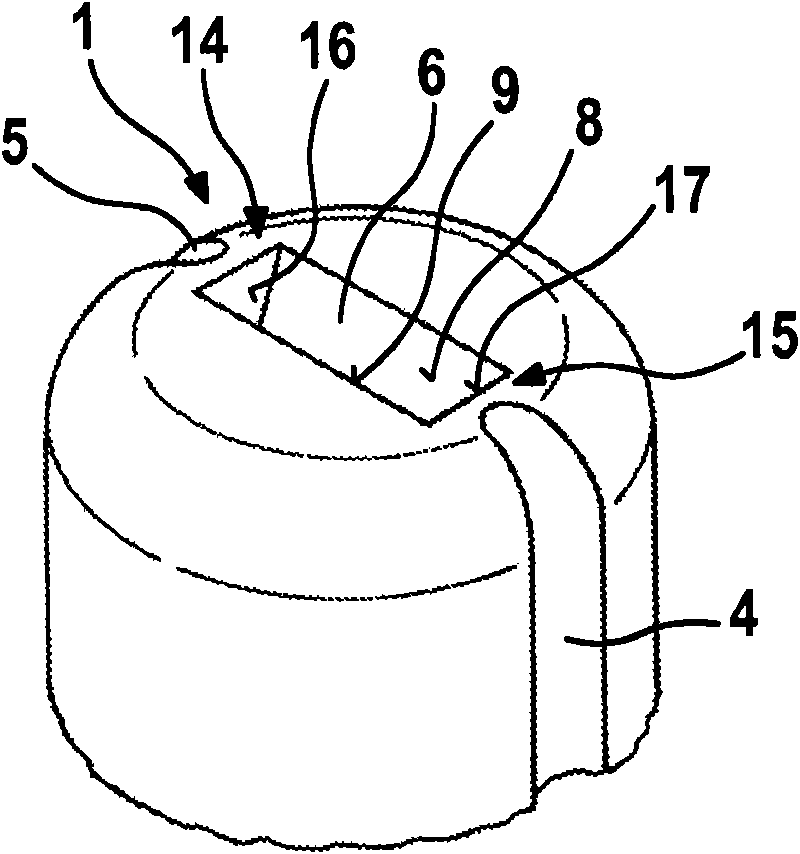

Tensioning device comprising at least two ventilation elements

InactiveCN103154570AIncrease the lengthMake the transitionGearingEngineeringInternal combustion engine

The invention relates to a tensioning device (8) for an endless drive element, in particular a timing chain (5) of an internal combustion engine, comprising a housing (10), a tensioning piston (11) which can be movably guided in the housing (10), and a pressure chamber (19) for a hydraulic fluid, formed between the housing (10) and the tensioning piston (11), wherein the tensioning piston (11) has a ventilation opening (15) and a ventilation channel (23, 16.1, 16.2, 16.3, 22.1, 22.2, 22.3) is provided which is disposed between the pressure chamber (19) and the ventilation opening (15) and which is formed by the assembly of at least two ventilation elements. In one ventilation element, in the surface (E) which contacts the second ventilation element, sub-regions of the ventilation channel which are separated from one another are formed by indented groove sections (16.1, 16.2, 16.3, 22.1, 22.2, 22.3), which are connected to one another by transitional grooves (22.1, 22.2, 22.3) formed in the second ventilation element in the surface which contacts the first ventilation element in such a way that a main part of the flow cross-section of the ventilation channel is disposed with some sections on one side and some sections on the other side of a plane spanned by the contact surfaces. The invention further relates to a corresponding traction drive (1) having such a tensioning device (8).

Owner:IWIS MOTORSYSTEME GMBH & CO KG

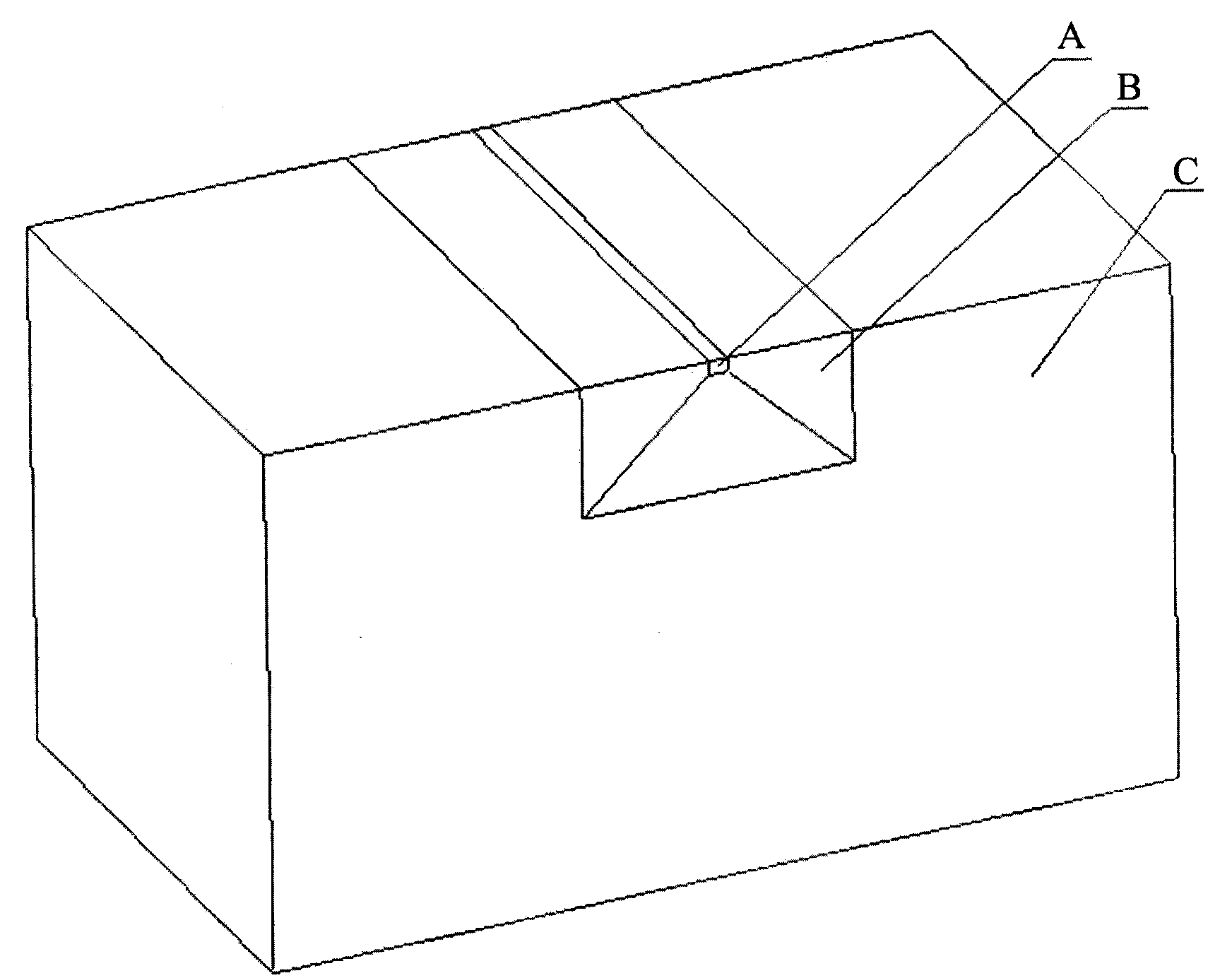

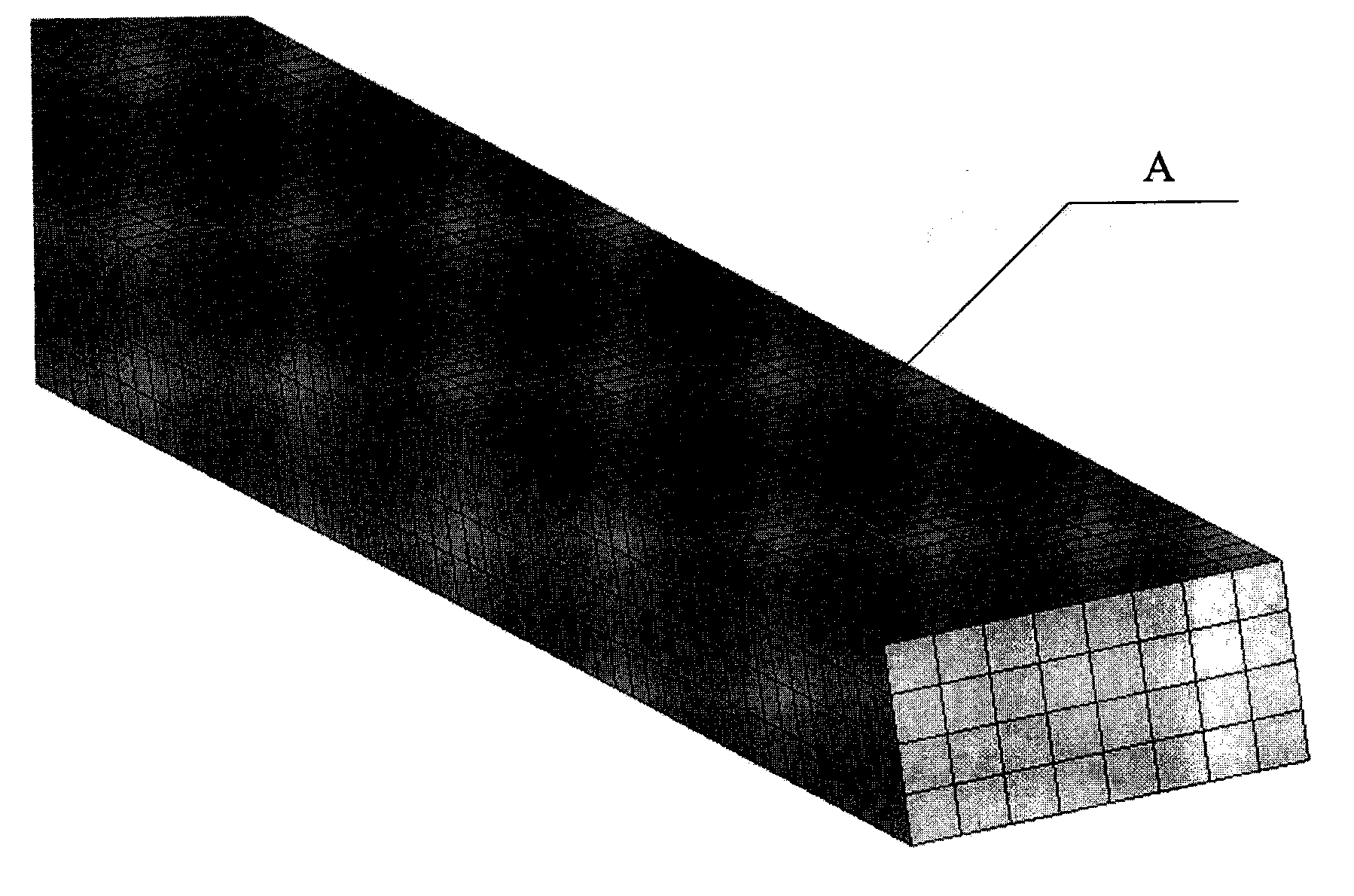

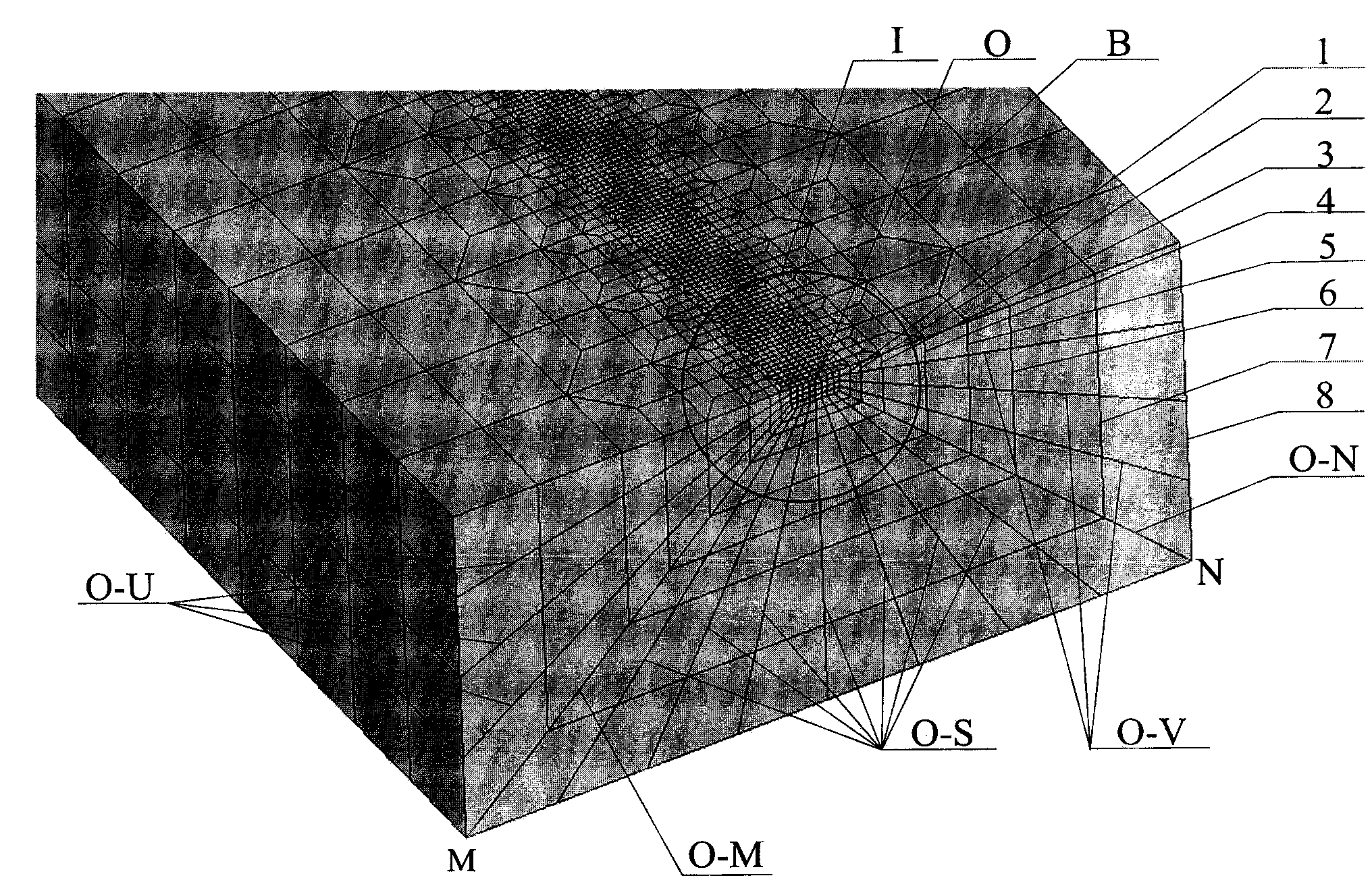

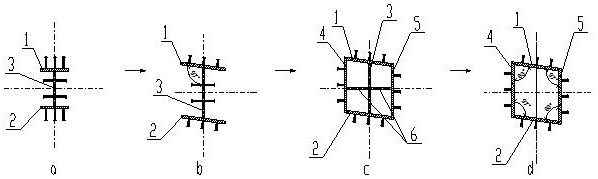

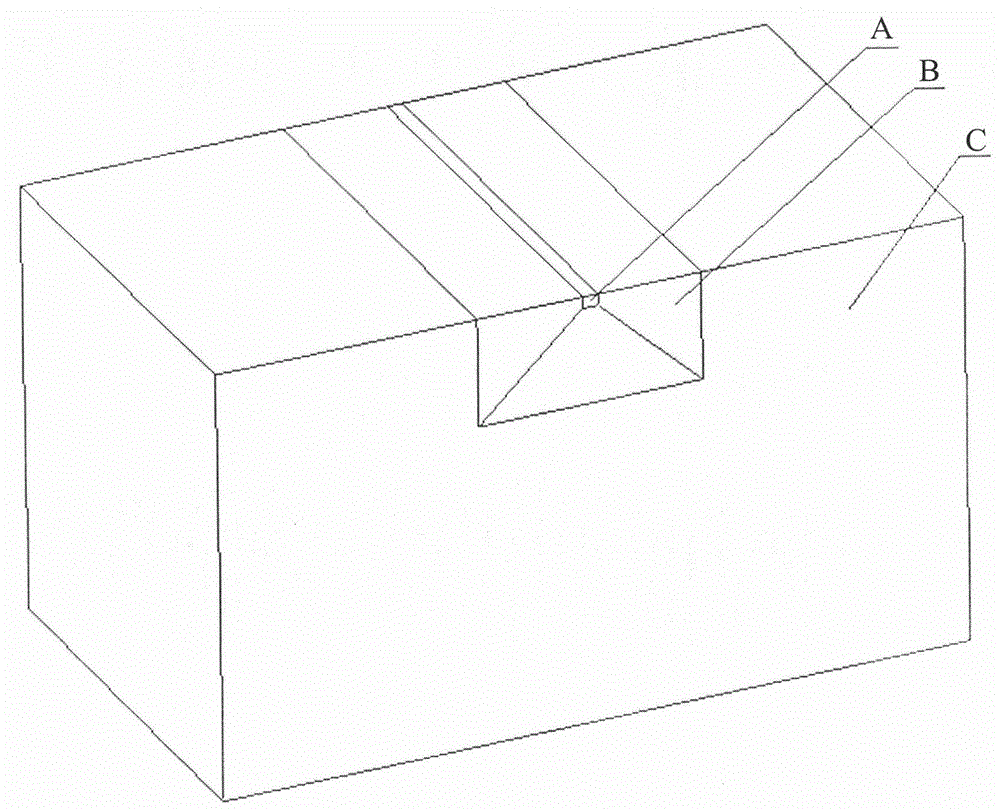

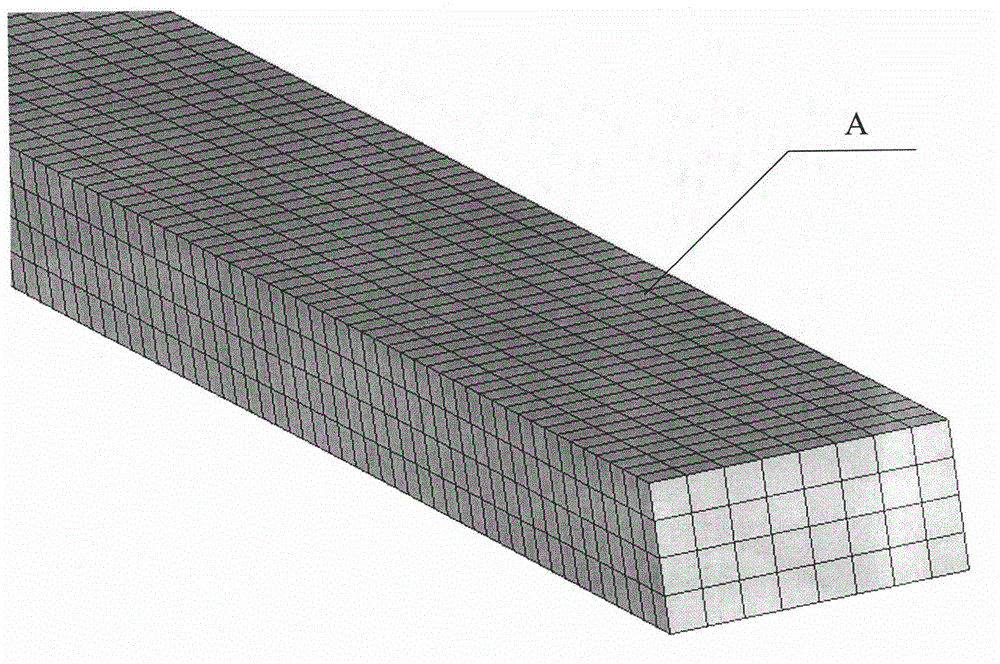

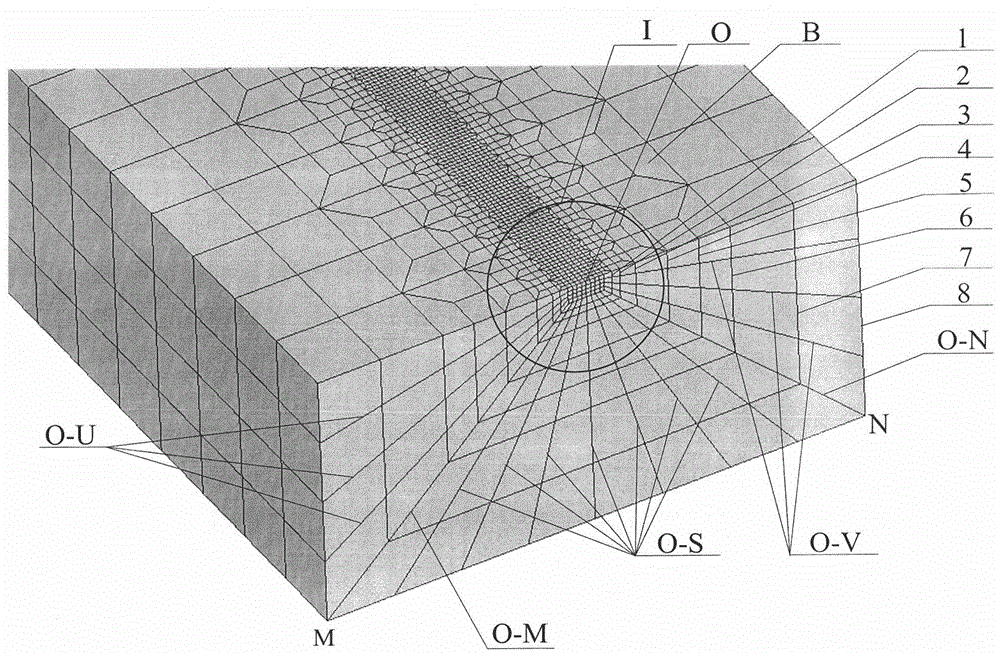

Method for quick transition of finite element three-dimensional model grids

ActiveCN103530463AImprove computing efficiencySave the total number of gridsSpecial data processing applicationsThree dimensional modelGrid partition

The invention discloses a method for quick transition of finite element three-dimensional model grids, relates to a method for finite element model grid transition and aims at solving the problem that an existing grid transition method is only limited to a single-direction transition means, namely, in the single direction, the grid size proportion of a far end and a short end is 2 or 3 and is used as the transition proportion to conduct multiple times of grid transition, and the means can not realize the finite element simulation of large components. The method comprises the steps of dividing a component into an important area, a transition area and a non-important area according to the size of calculation data change gradient of different parts of the component; dividing the important area into a plurality of grids in a shape of a cube or a cuboid, wherein grids in the important area A should be dense; conducting transition grid division on the transition area; dividing the non-important area into a plurality of grids in a shape of a cube or a cuboid, wherein grids in the non-important area should be sparse. Consequently, the grid division of the whole component is finished. The method is used for grid division of finite element model simulation modeling of a large or super large component.

Owner:HEILONGJIANG INST OF TECH

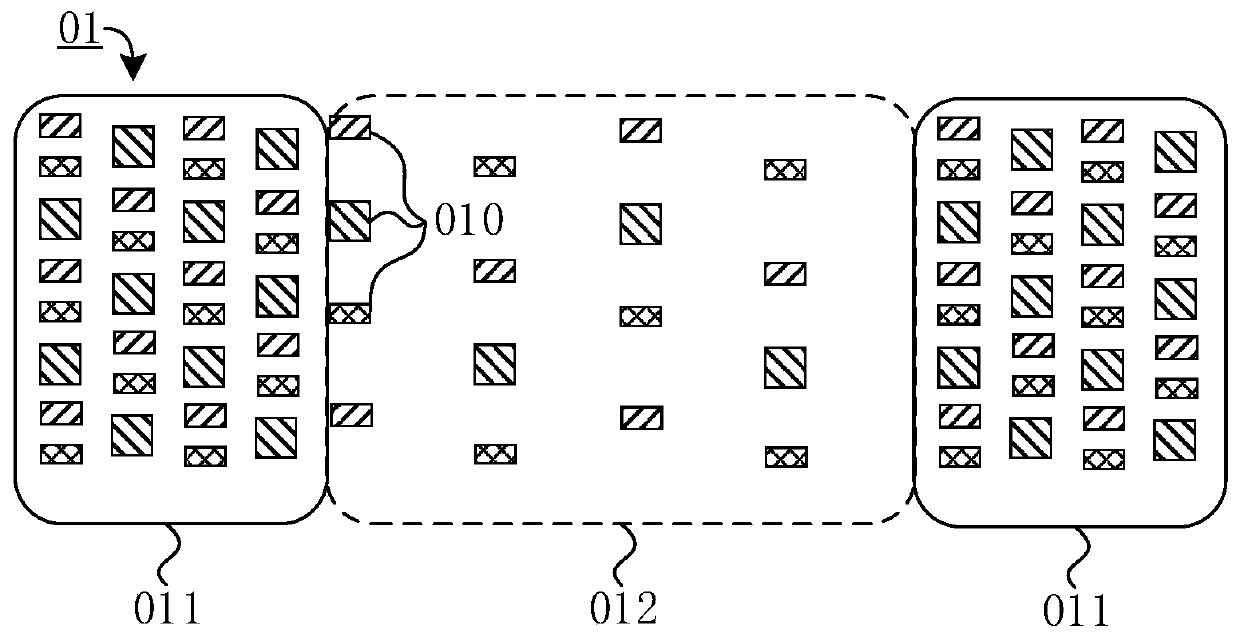

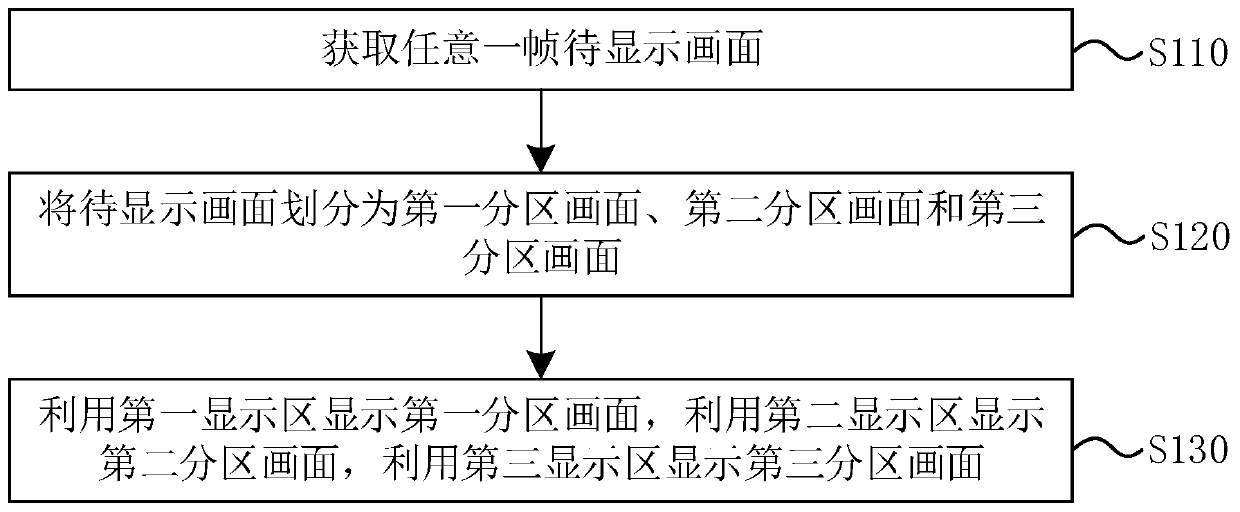

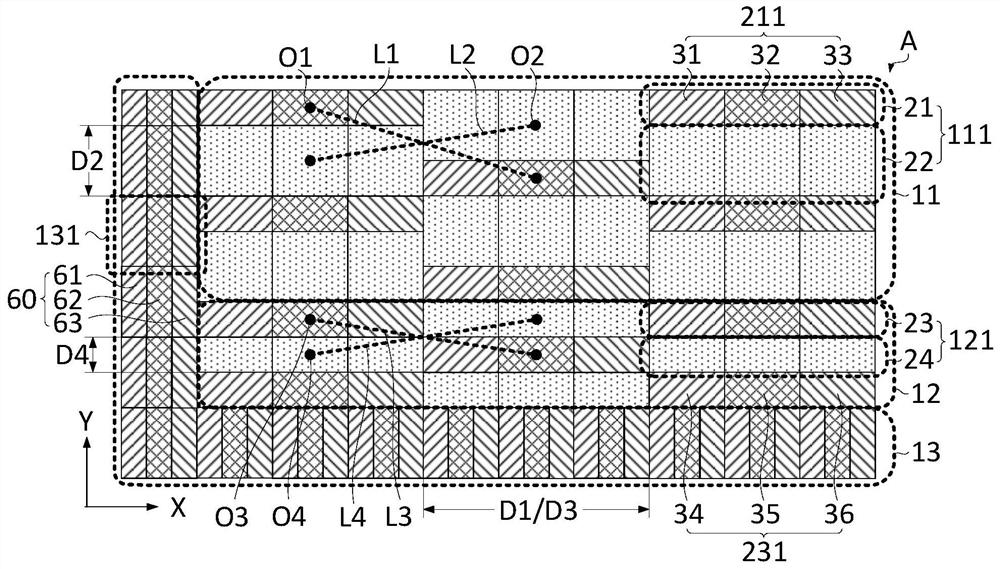

Display panel driving method, display driving device and electronic equipment

ActiveCN110675835AMake the transitionWeaken Partition BoundariesImage analysisStatic indicating devicesPixel densityEngineering

The embodiment of the invention discloses a display panel driving method, a display driving device and electronic equipment. The driving method comprises the following steps: acquiring any frame of to-be-displayed picture; dividing the picture to be displayed into a first partition picture, a second partition picture and a third partition picture; displaying the first partition picture by using the first display area, displaying the second partition picture by using the second display area, and displaying the third partition picture by using the third display area, wherein in the same frame ofpicture to be displayed, the sub-pixel density A1 for displaying the first partition picture, the sub-pixel density A2 for displaying the second partition picture and the sub-pixel density A3 for displaying the third partition picture meet the condition that A2 is larger than A1 and smaller than or equal to A3; the sub-pixels of the second display area comprise the first sub-pixels and the secondsub-pixels, and the display brightness L21 of the first sub-pixels and the display brightness L22 of the second sub-pixels meet the condition that L21 is larger than L22. According to the technical scheme, transition of the image quality and the brightness in the to-be-displayed image can be achieved through the second display area, and therefore the overall display quality can be improved.

Owner:WUHAN TIANMA MICRO ELECTRONICS CO LTD

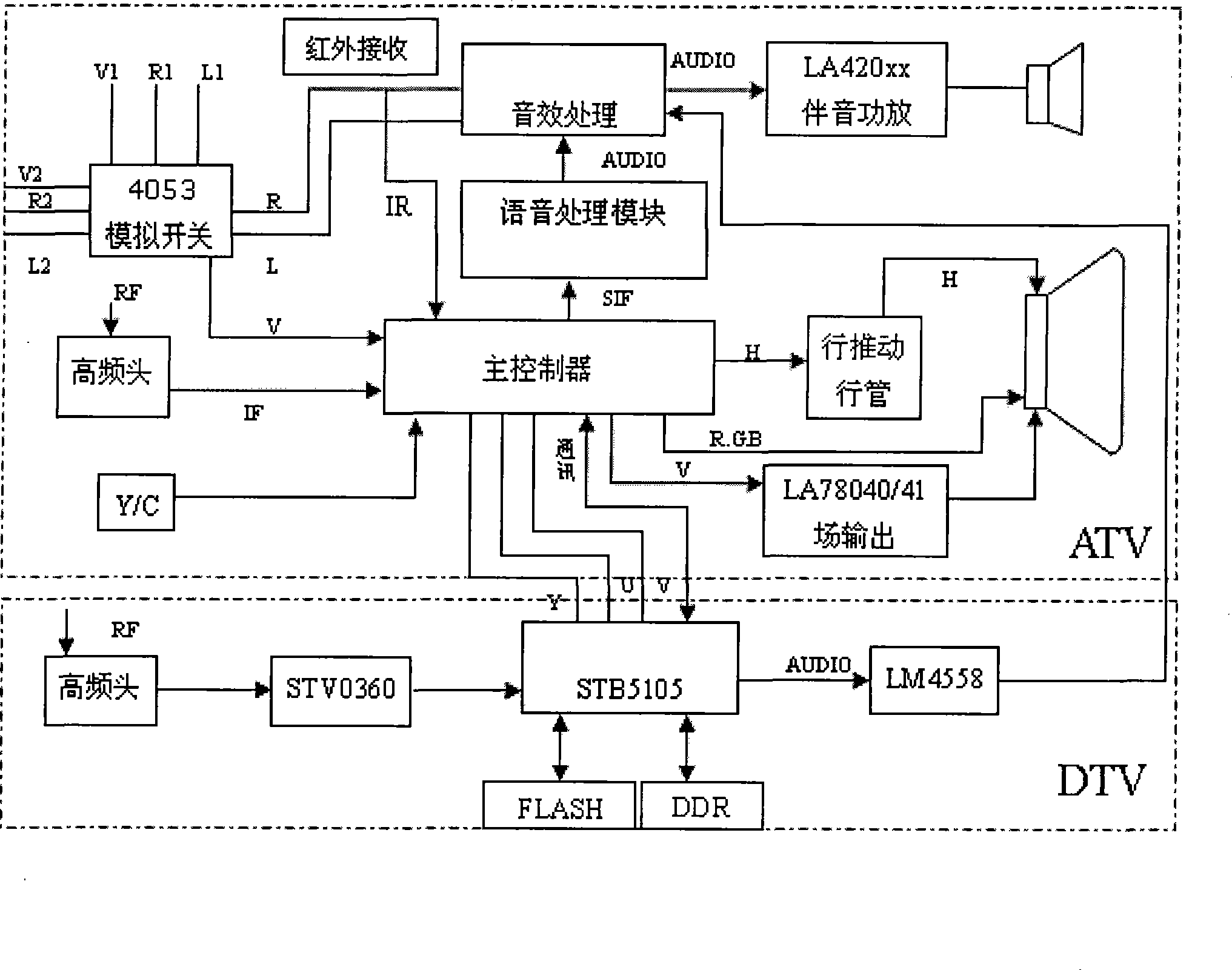

Digital analog integrated color television receiving system

InactiveCN101426108ASolve the problem of not being able to receive digital signalsMake the transitionTelevision system scanning detailsDigital signal processingSpeech Processor

The invention discloses a digital-analog integrated color television receiver system, including a tuner, a main controller, an audio processor and a video processor, wherein, the tuner inputs radiofrequency signals for watching the programs and outputs IF intermediate frequency signal of programs required to watch; the main controller performs magnification and chrominance encoding to the IF signal of the watching program, outputs the audio signal onto the audio processor and outputs the video signal onto the video processor, the main controller is connected to a digital signal processor, which performs demodulation and decoding process to the IF signal of the watching program output by the tuner and outputs audio signals to the audio processor. Compared with the existing technology, the invention can not only receive digital TV signals but also can receive analog TV signals, digital TV can not be resolved to receive analog signals, analog television to receive digital signals can not be the problem, realizes the transition from analog TV to digital TV, and the invention can complete the entire operation only by a remote controller, for simplifying the users' operations.

Owner:深圳市启欣科技有限公司

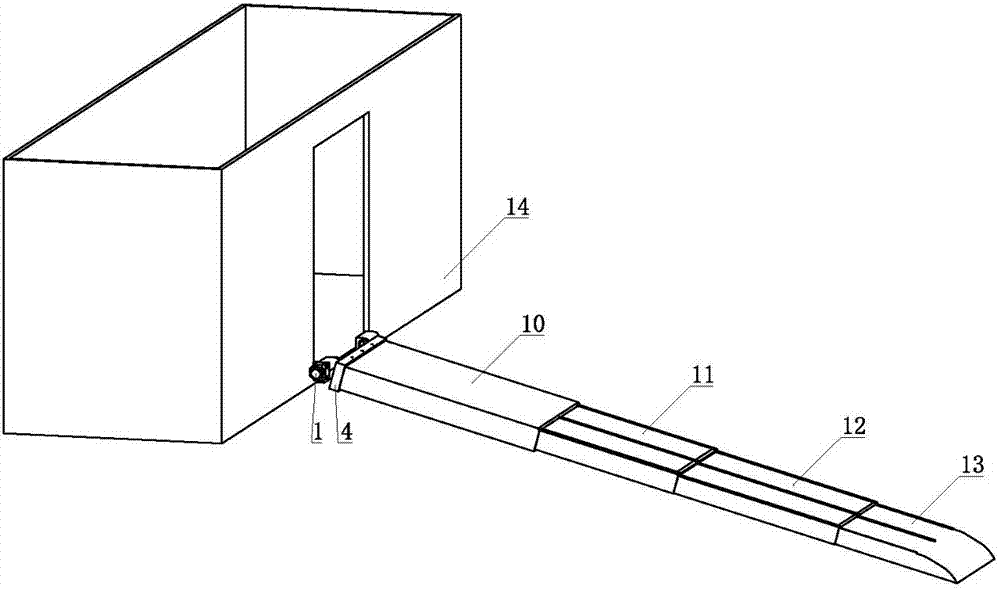

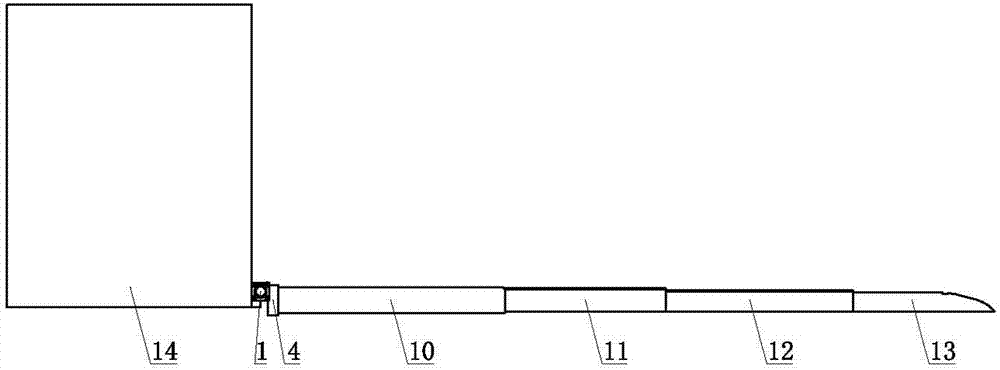

Device for electric telescopic forklift getting on and off railway wagon

PendingCN106945683AMake the transitionAdapt to different height differencesRailway device loading/unloadingElectric machineryMoving parts

The invention discloses a device for an electric telescopic forklift getting on and off a railway wagon which mainly consists of motors, pins, a connecting seat, a lead screw, a nut moving part, a bearing, a parallelogram telescopic mechanism, transition plates, fastening screws and the like. The device achieves the turning over of self by using a motor and achieves the expansion and contraction of the parallelogram telescopic mechanism by using another motor to drive a lead screw and nut pair, thereby driving the expansion and contraction of the transition plates for realizing the transition of the railway wagon and a platform at different slope angles, so that the complicated and tedious work of building a skew bridge between the railway wagon and the platform is eliminated. The device for the electric telescopic forklift getting on and off the railway wagon has the advantages of simple structure, small size, quick and convenient use, onboard portability and reliable performance, and is suitable for situations of loading and unloading goods on trains in the course of railway transportation.

Owner:EAST CHINA JIAOTONG UNIVERSITY

Method for transition from non-pillar sublevel caving method to upward horizontal cut-and-fill method

InactiveCN103557029AMake the transitionHigh recovery rateMaterial fill-upVegetationEcological environment

The invention relates to a method for transition from a non-pillar sublevel caving method to an upward horizontal cut-and-fill method. The technical scheme is as follows: in a section close to and below a caved area (1) of a mining area, the section is divided into an isolation zone (2) and a recovery area (3), the upper part of the section is the isolation zone (2), and the lower part of the section is the recovery area (3). The section is exploited in such a sequence that the recovery area is exploited before the isolation zone (2) is exploited. An exploitation method of the section is as follows: the upward horizontal cut-and-fill method is adopted for the recovery area (3), and the non-pillar sublevel caving method is adopted for the isolation zone (2). The thickness of the isolation zone (2) is one or two times of the sublevel height of the non-pillar sublevel caving method. The isolation zone (2) is exploited after final setting of a filling body of the recovery area (3). The method has the characteristics that the loss ratio of ore can be reduced, the dilution rate can be reduced, the surface vegetation and the ecological environment can be protected, atmospheric conditions of a stope can be improved, and the recovery is simple.

Owner:WUHAN UNIV OF SCI & TECH

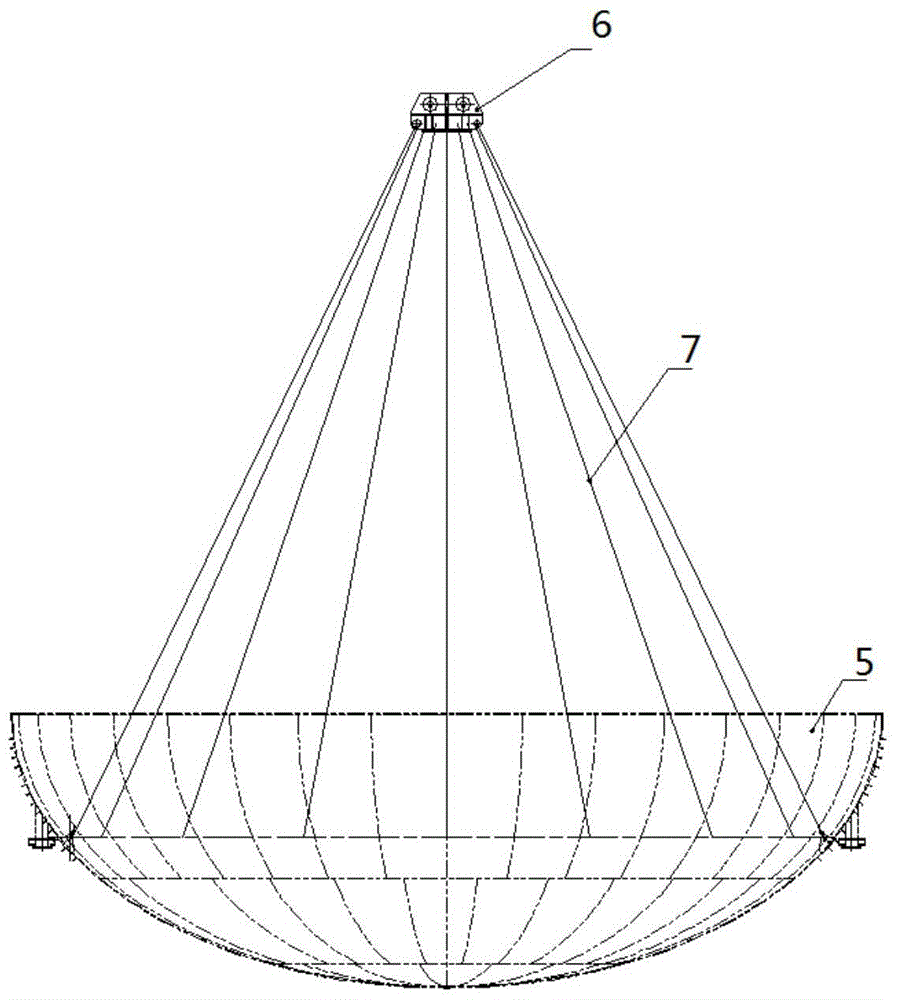

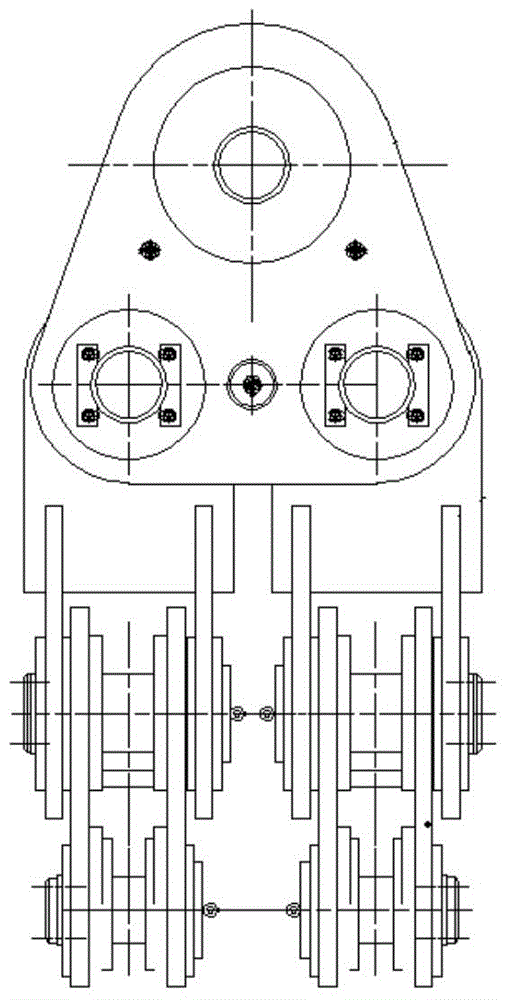

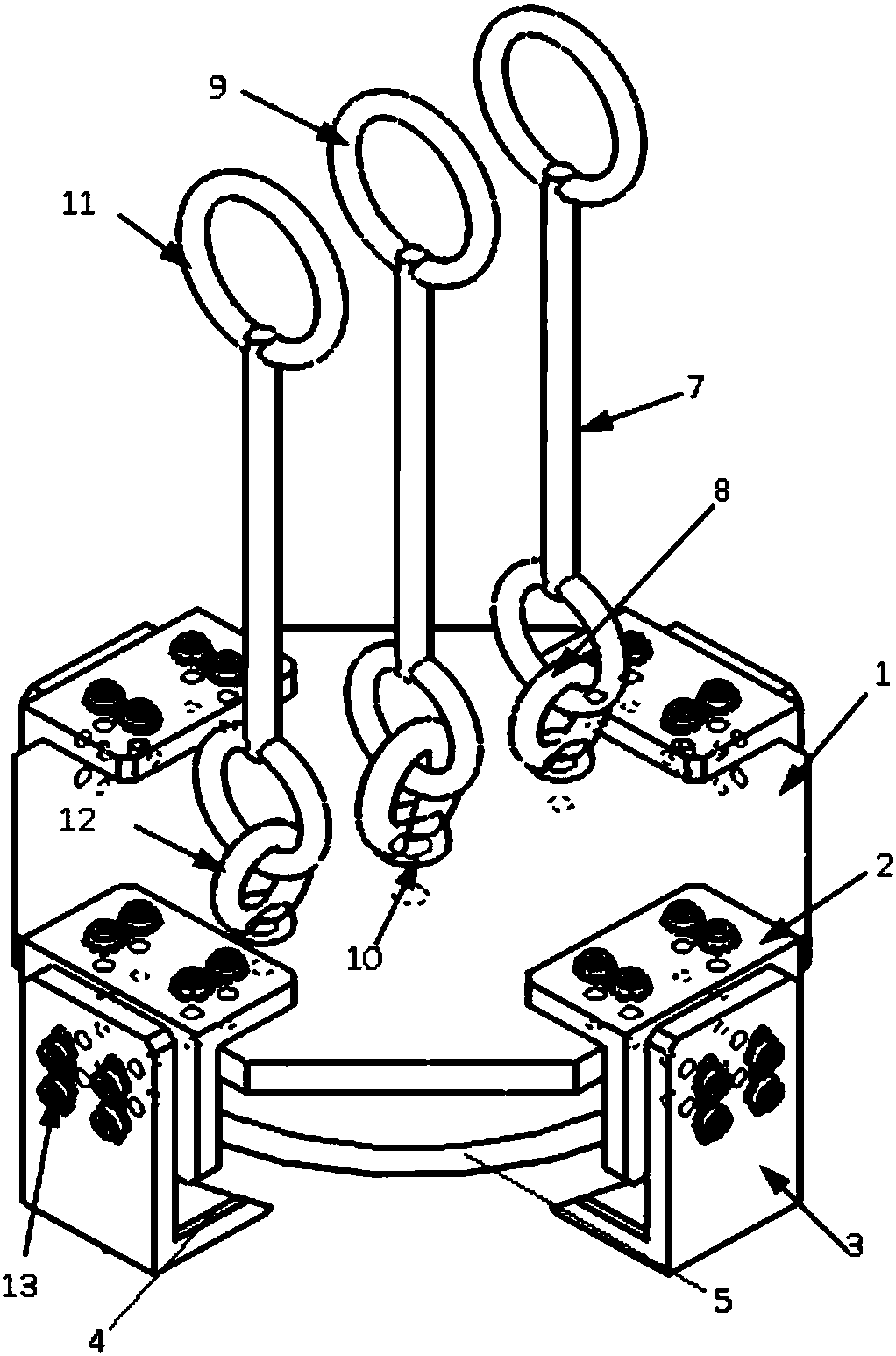

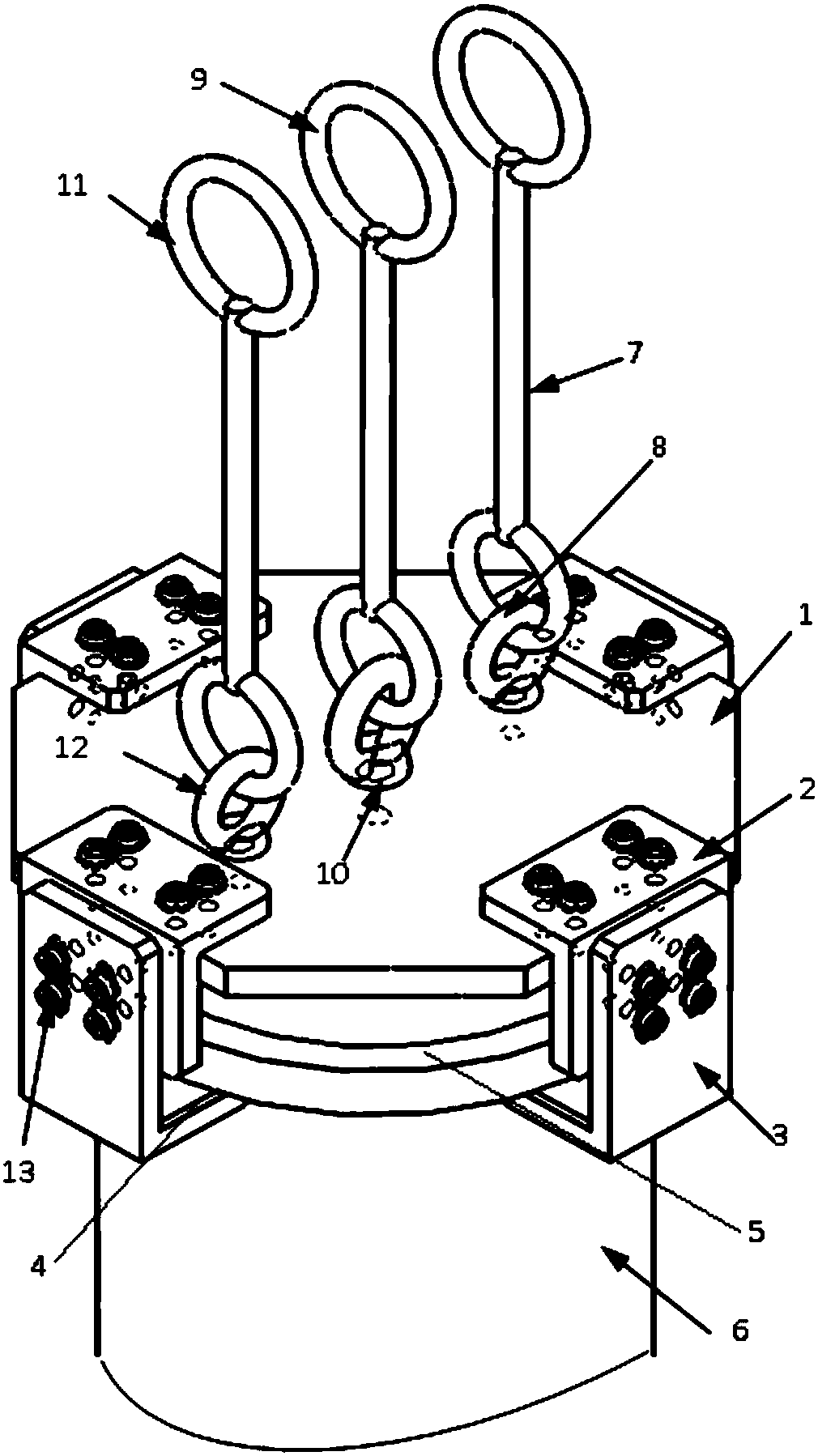

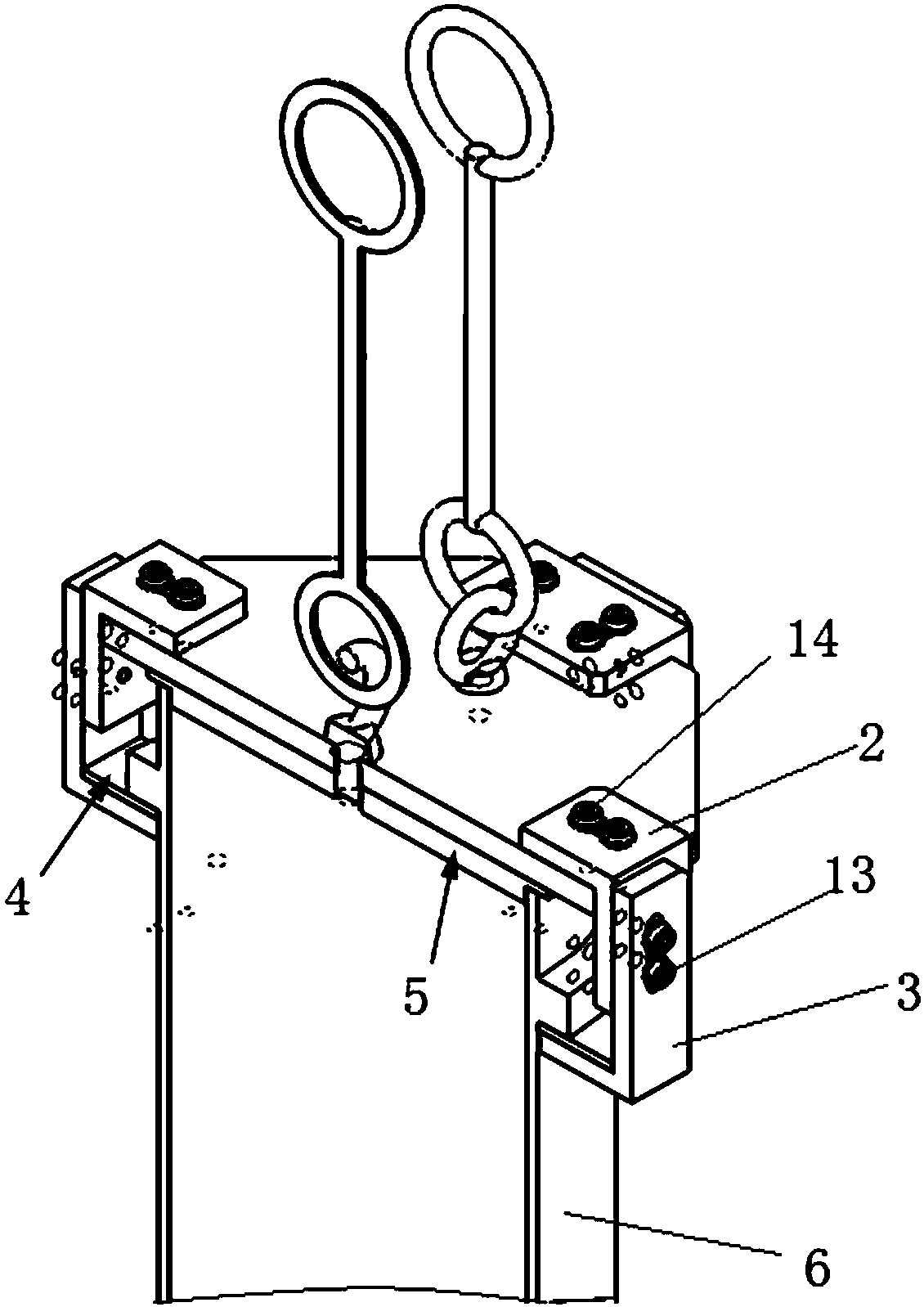

Novel nuclear power plant steel containment spreader

InactiveCN104891324ACentrosymmetric implementationReasonable forceLoad-engaging elementsDistributorSymmetric structure

The present invention discloses a novel nuclear power plant steel containment spreader, including a dispenser, a wire rope sling and an angle adapter device. The upper part of the dispenser is provided with a main hanging board in cross structure; the lower part of the dispenser is provided with branch boatswain chair distributors along a circumferential direction; the whole structure is centrally symmetric, and reasonable in bearing; under the hanging article is in a similar weight, the centrally symmetric structure can significantly reduce the weight of the dispenser. The angle adapter device contains an angle adapter and a double level balance beam; the angle adapter adjust the axes of the pin apertures on the directions of 0 DEG, 90 DEG, 180 DEG and 270 DEG on the main hanging board of the dispenser to a same direction in parallel to each other, so that the angle adapter is conveniently connected to the double level balance beam.

Owner:SHANGHAI NUCLEAR ENG RES & DESIGN INST CO LTD

Manufacturing method for composite steel column of transition section of tower crown of super high-rise building

ActiveCN111644727AImprove bearing capacityReduce dockingStrutsArc welding apparatusSteel columnsTower

The invention discloses a manufacturing method for a composite steel column of a transition section of a tower crown of a super high-rise building. The composite steel column comprises a steel columnwhich is vertically arranged, upper brackets and lower brackets, wherein the upper brackets and the lower brackets are arranged on the steel column at intervals, and the steel column is sequentially composed of an orthogonal H-shaped steel column section, a connecting H-shaped steel column section, an oblique-crossing H-shaped steel column section and a rhombic steel column section from bottom totop; center lines of webs of the orthogonal H-shaped steel column section, the connecting H-shaped steel column section and the oblique-crossing H-shaped steel column section are located in the same straight line; the lower brackets are arranged on the connecting H-shaped steel column section; and a left flange plate and a right flange plate are correspondingly arranged between an upper flange plate and a lower flange plate of the upper end of the oblique-crossing H-shaped steel column section, the two sides of the left flange plate and the right flange plate are correspondingly and fixedly connected with the edge of the lower flange plate and the edge of the corresponding upper flange plate, so as to close the left and right sides of the upper flange plate and the lower flange plate, andan inclination angle of the rhombic steel column section corresponds to that of the tower crown. According to the manufactured composite steel column, the transition from the main structure of a towerbuilding to the tower crown structure can be effectively achieved.

Owner:中冶建工集团重庆建筑工业有限公司

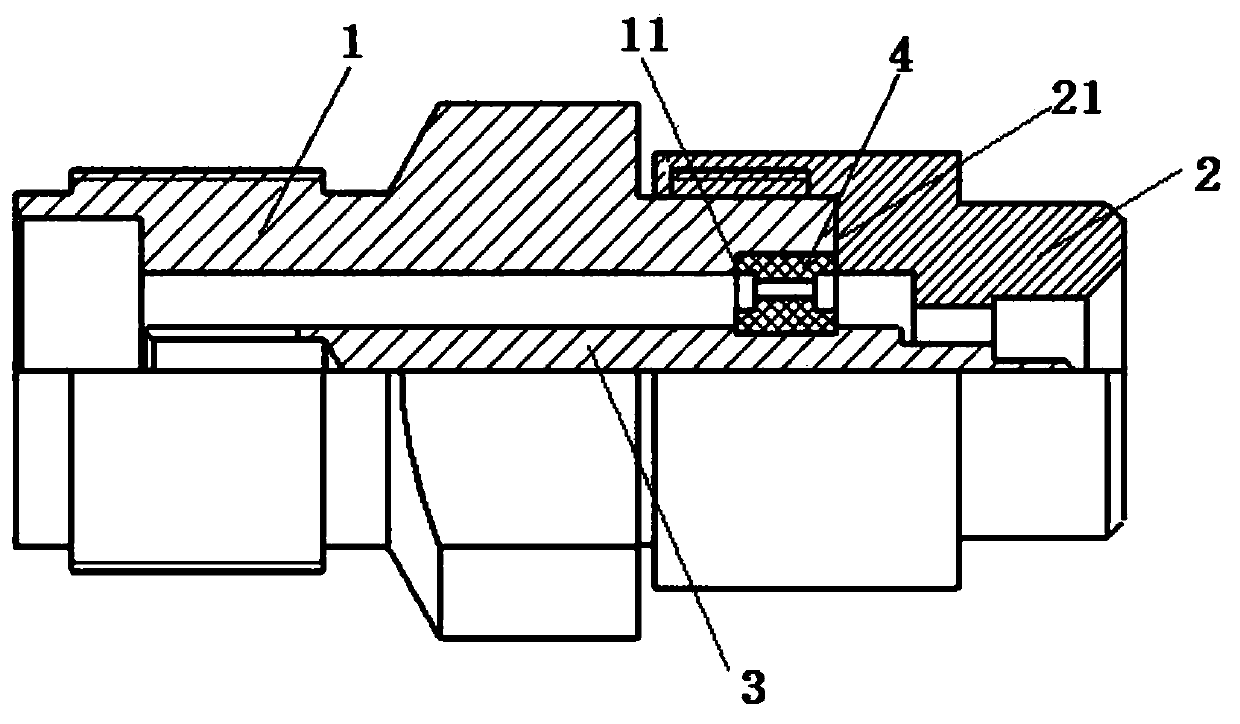

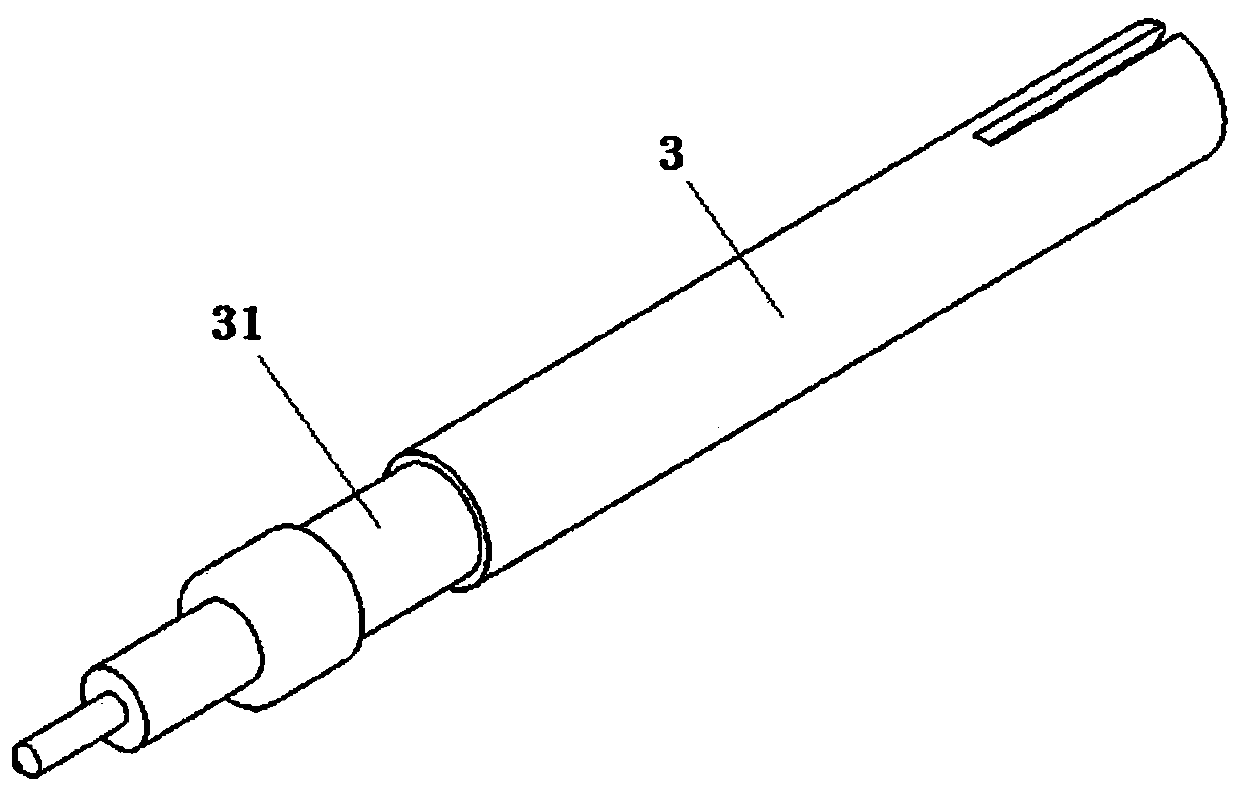

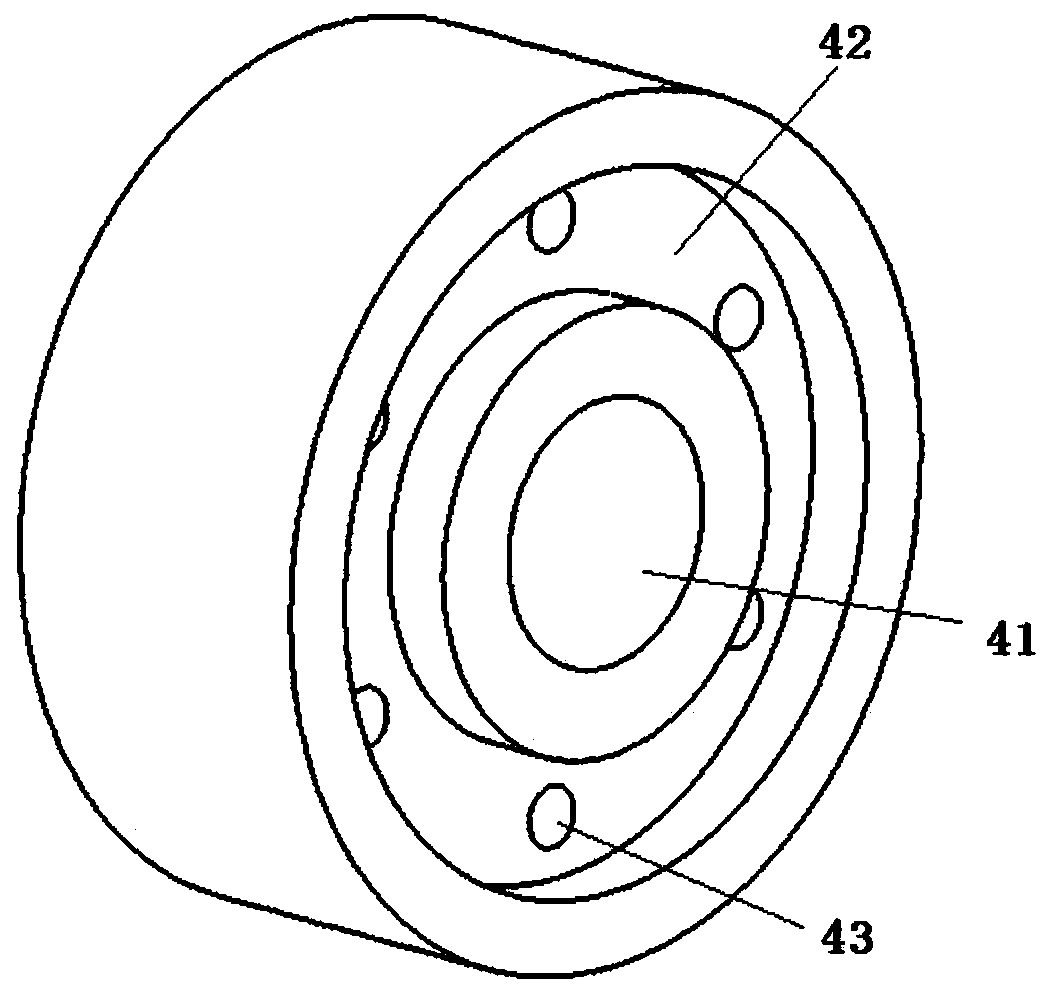

Single-support medium coaxial adapter with capacitive compensation

PendingCN111064057ALow relative permittivityReduce reflectionCoupling device detailsTwo-part coupling devicesMicrowave electronicsStructural engineering

The invention relates to the technical field of microwave electronic equipment interconnection, and discloses a single-support medium coaxial adapter with capacitive compensation. The single-support medium coaxial adapter is characterized by comprising an SMA jack shell (1), an SMPM pin shell (2) and a stub assembly, the stub assembly comprises an inner stub (3) and an insulation support medium (4) which are coaxially arranged, the insulation support medium (4) is fixed on the outer peripheral surface of the inner plug (3), the plug assembly is inserted into the SMA jack shell (1) from one endfar away from the insulation support medium (4), a first step structure (11) is arranged in the SMA jack shell (1), a second step structure (21) is arranged in the SMPM pin shell (2), and when the SMA jack shell (1) and the SMPM pin shell (2) are in an inserted state, the SMPM pin shell (2) and the SMA jack shell (1) are connected through threads, and the two ends of the insulation supporting medium (4) abut against the first step structure (11) and the second step structure (21) respectively.

Owner:沈阳兴华航空电器有限责任公司

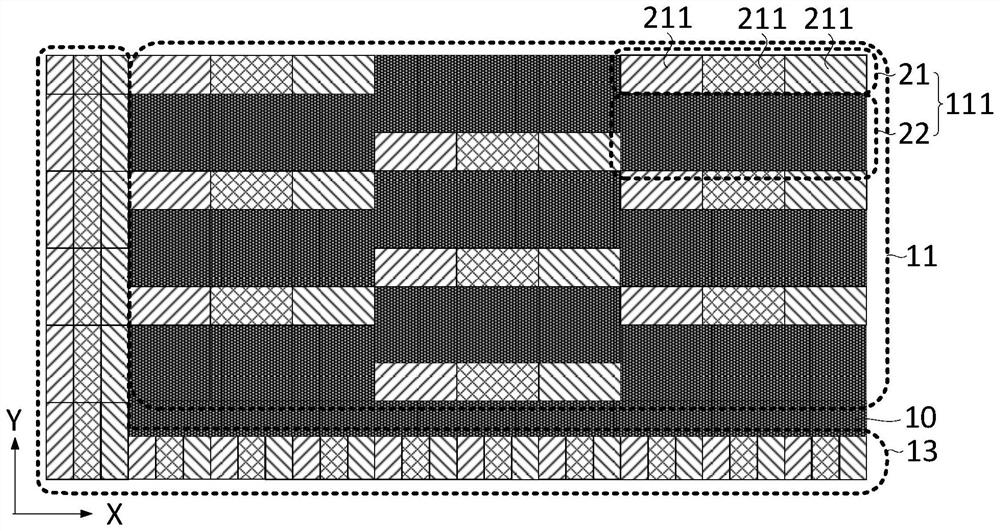

Display panel and display device

PendingCN112562569AAvoid compromising color purityGuaranteed color saturationStatic indicating devicesComputer hardwareComputer graphics (images)

The invention discloses a display panel and a display device. The display panel comprises a first display area, a second display area and a third display area which are adjacently arranged in sequence, wherein the first display area comprises a plurality of first pixel units arranged in an array mode, the second display area comprises a plurality of second pixel units arranged in an array mode, each first pixel unit comprises a first sub-pixel unit and a first light-transmitting area, each second pixel unit comprises a second sub-pixel unit and a second light-transmitting area, and the area ofthe second light-transmitting area is smaller than that of the first light-transmitting area. According to the display panel provided by the embodiment of the invention, human eyes are insensitive tothe reduced dark area by reducing the area of the dark area formed by the second light-transmitting area, so that the first display area and the third display area have transition areas by arrangingthe second display area, the phenomenon of uneven display in visual effect between the first display area and the third display area is improved, and the display effect of the display panel is improved.

Owner:XIAMEN TIANMA MICRO ELECTRONICS

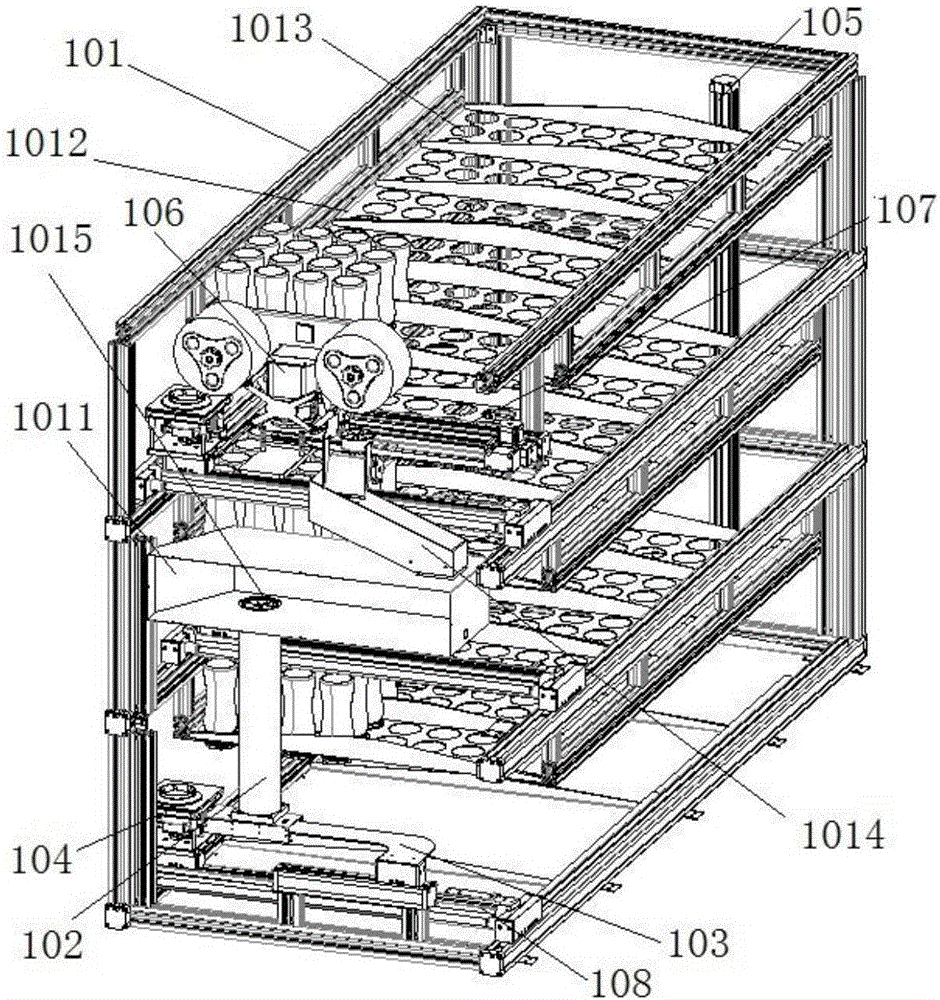

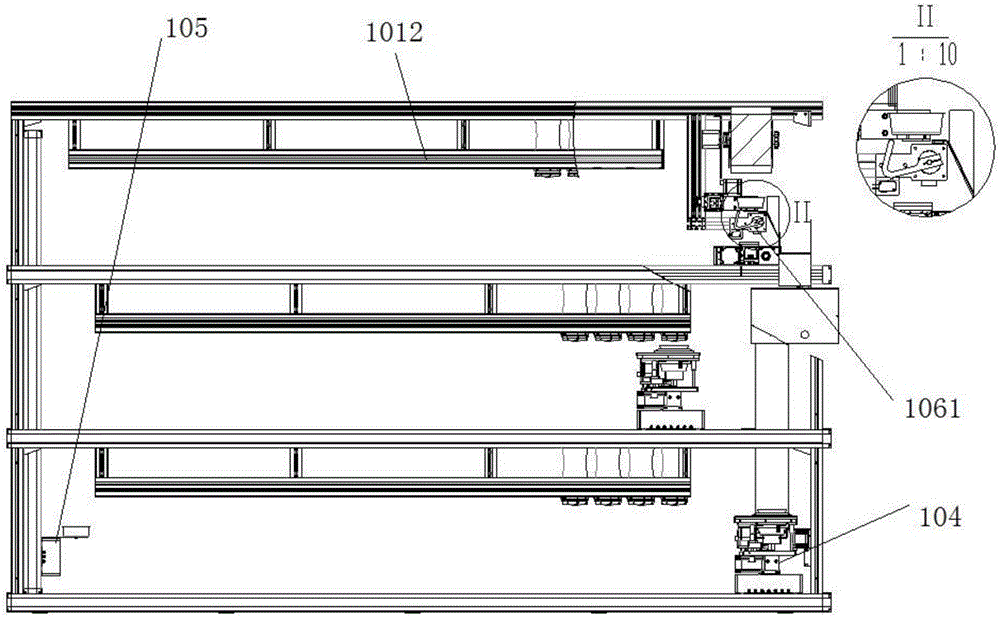

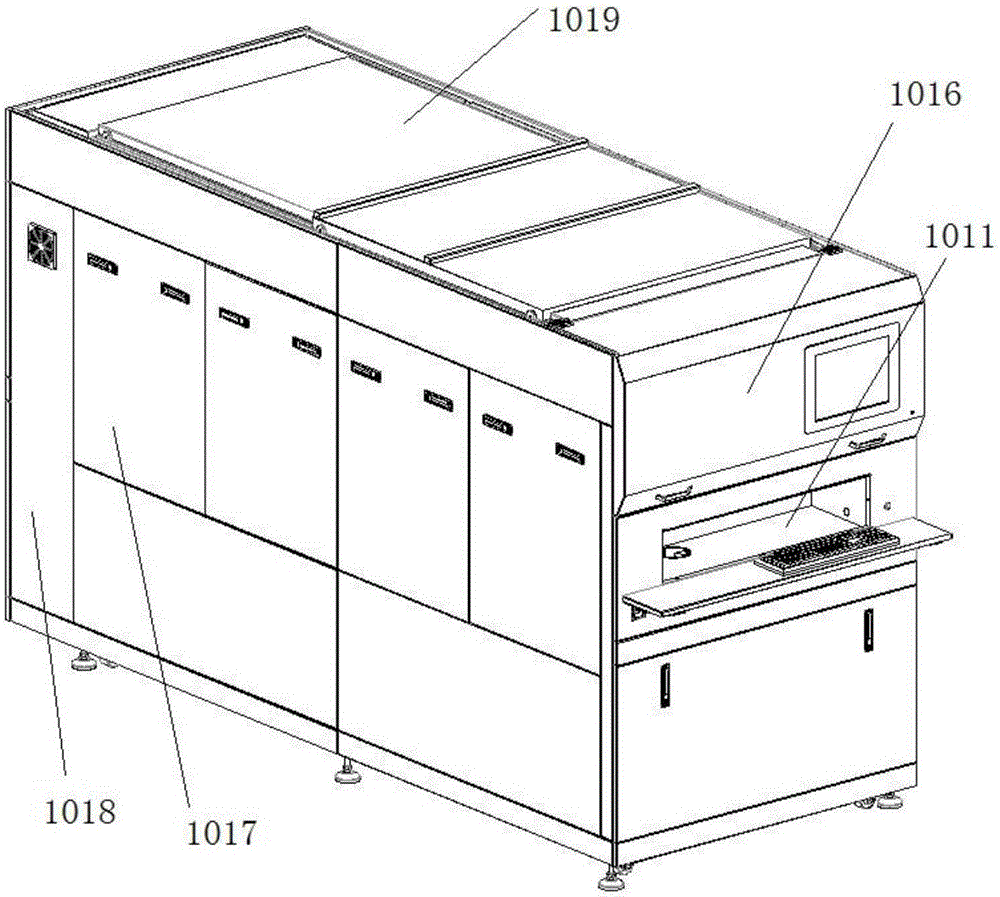

Multi-layer medicine dispensing machine

ActiveCN106697342AGuaranteed dockingGuaranteed disengagementSolid materialOperation roomBiomedical engineering

The invention discloses a multi-layer medicine dispensing machine. The multi-layer medicine dispensing machine comprises a machine frame body; a plurality of medicine bottle placing shelves are arranged in the machine frame body; a plurality of medicine bottle placing openings are formed in each medicine bottle placing shelf; a medicine dispensing mechanism is arranged below each medicine bottle placing shelf and is arranged on a left-right movement module, and the left-right movement module can do reciprocating rectilinear motion on installed machine frame guide rails; a front-back movement module is arranged between the medicine dispensing mechanism and the left-right movement module; the medicine dispensing mechanisms can run to any position of the plane where the medicine dispensing mechanism is located through the front-back movement module and the left-and-right movement module so as to carry out medicine dispensing; a picking and placing operation room is arranged on one side of the machine frame body; a medicine box placing inlet is formed in the position of the picking and placing operation room and is connected to a medicine box storage device; and a medicine box pushing mechanism is arranged at the bottom of the medicine box storage device. The multi-layer medicine dispensing machine has the advantages that the structure is ingenious, and multi-layer independent and synchronous medicine dispensing can be realized.

Owner:CHENGDU YH INTELLIGENT EQUIP TECH CO LTD

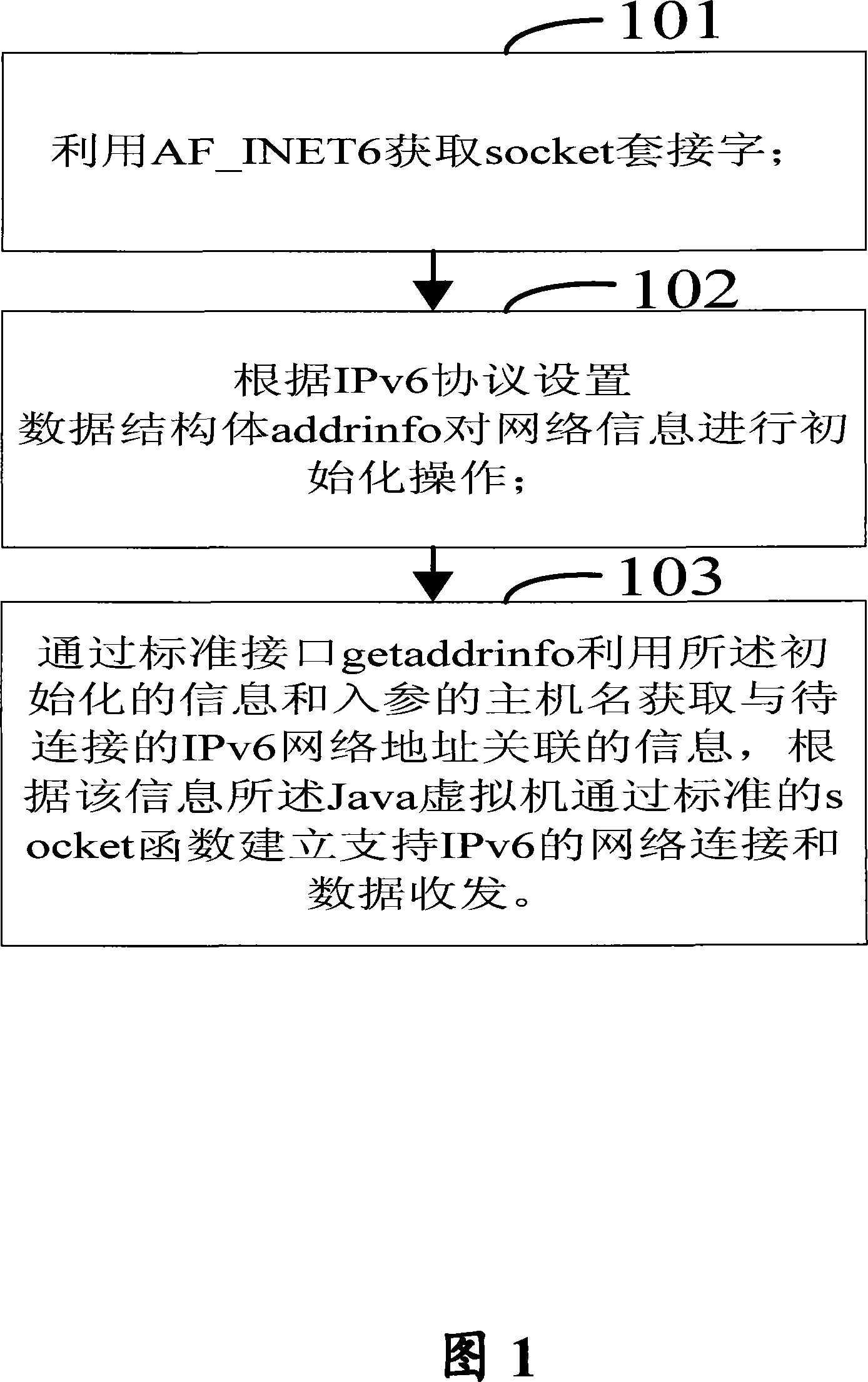

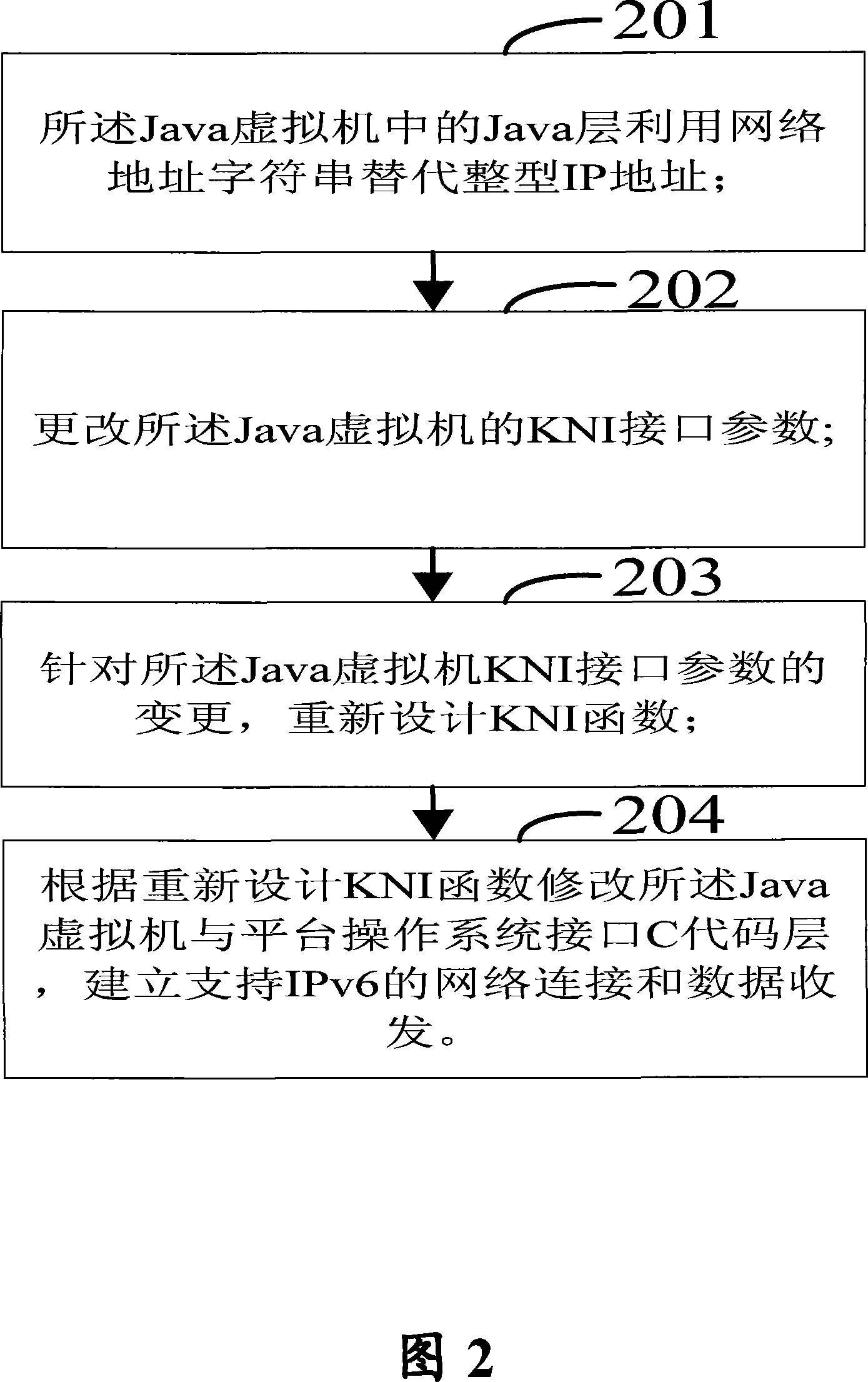

Implementation method for IPV6 supported by Java virtual machine

InactiveCN101079904AAlleviate needsAdd supportProgram loading/initiatingTransmissionInterface layerComputer module

This invention discloses a realization method for supporting IPv6 by Java virtual computers, which modifies a local interface layer and a protocol layer corresponding to a network operation module of the Java virtual computer to realize the support of the Java virtual computer to IPv6 protocol and a same Java operating under IPv4 can operate under the IPv6 environment so as to realize transformation of the Java virtual computer from IPv4 to IPv6.

Owner:ZTE CORP

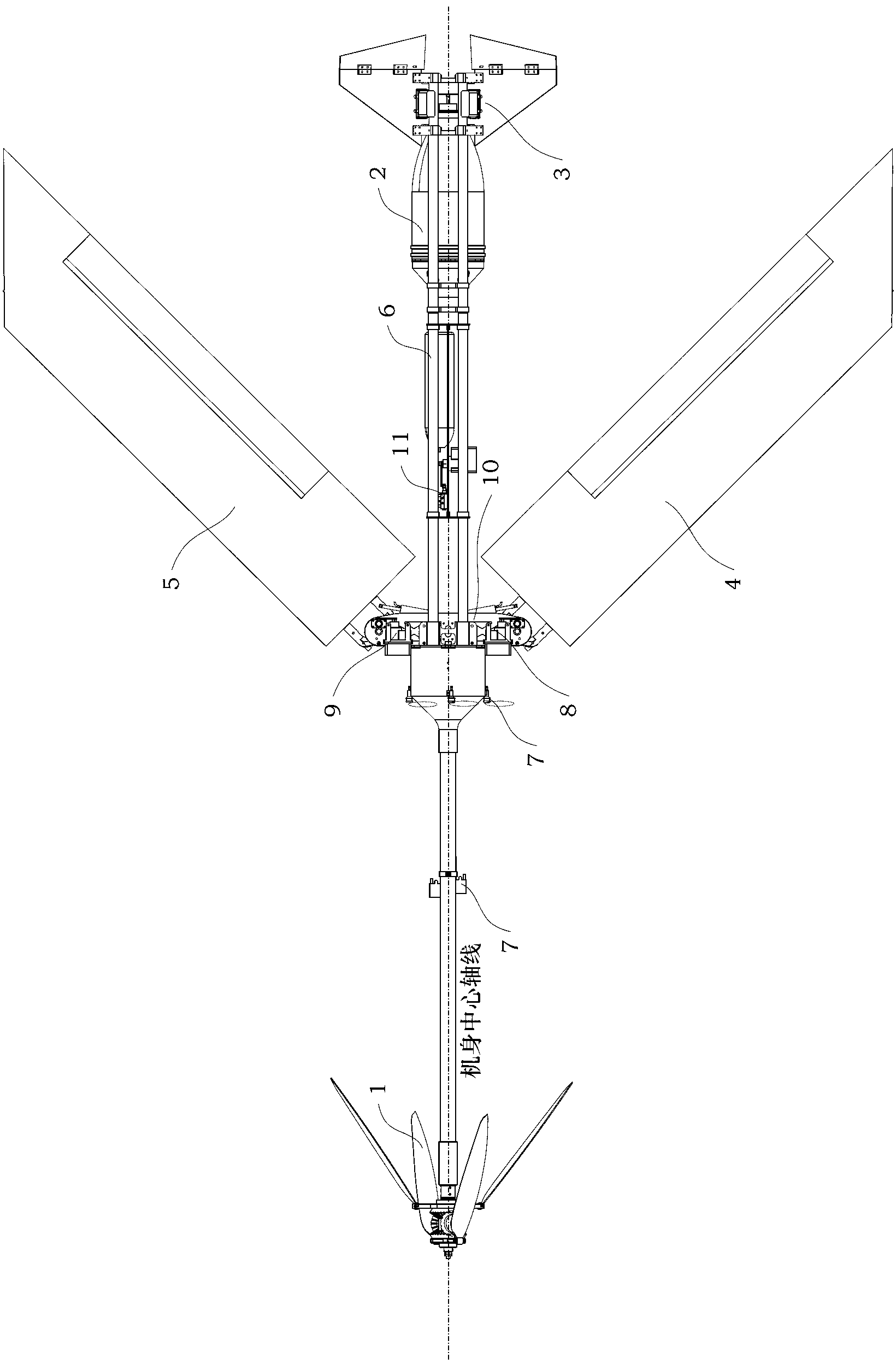

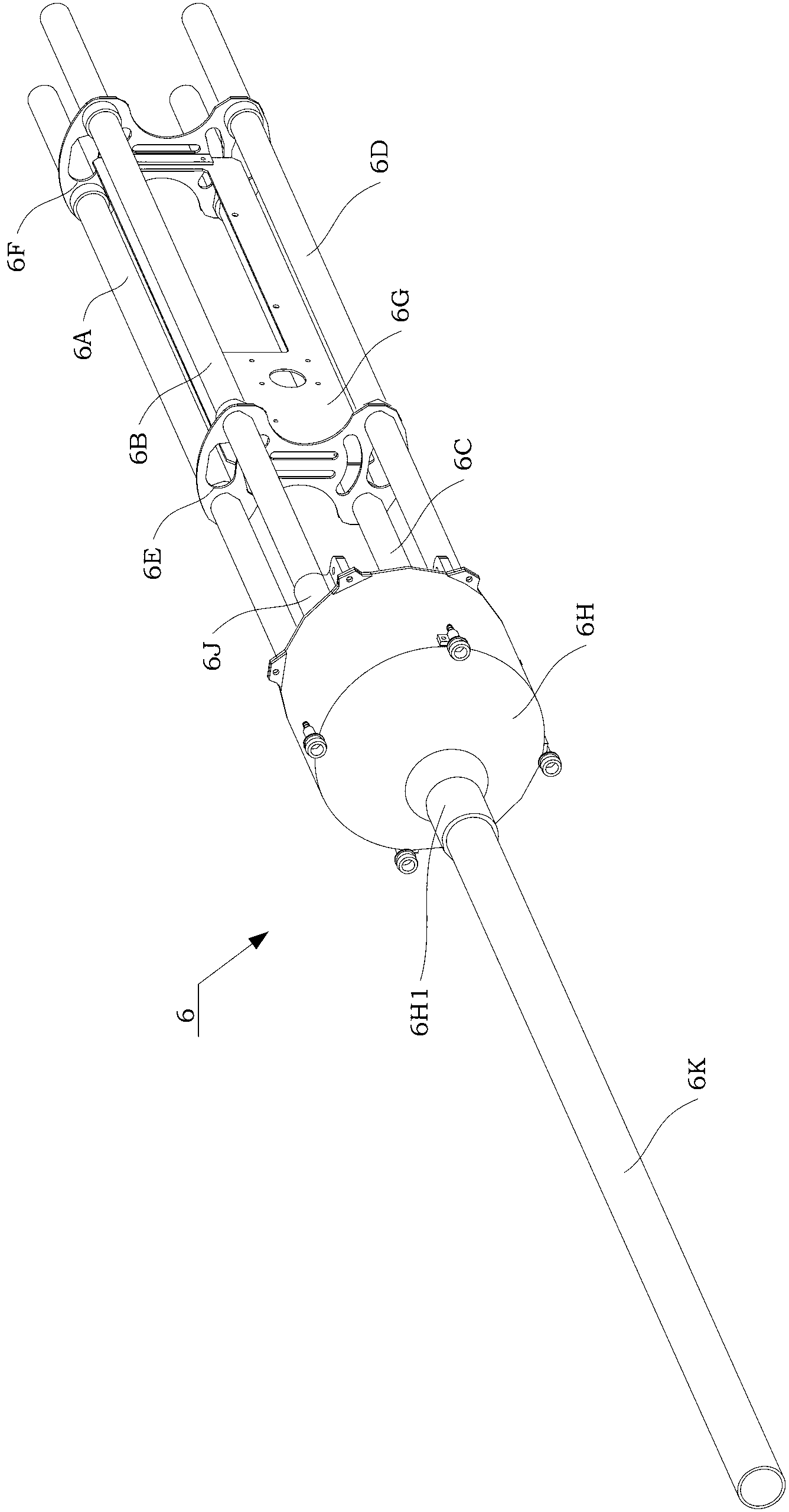

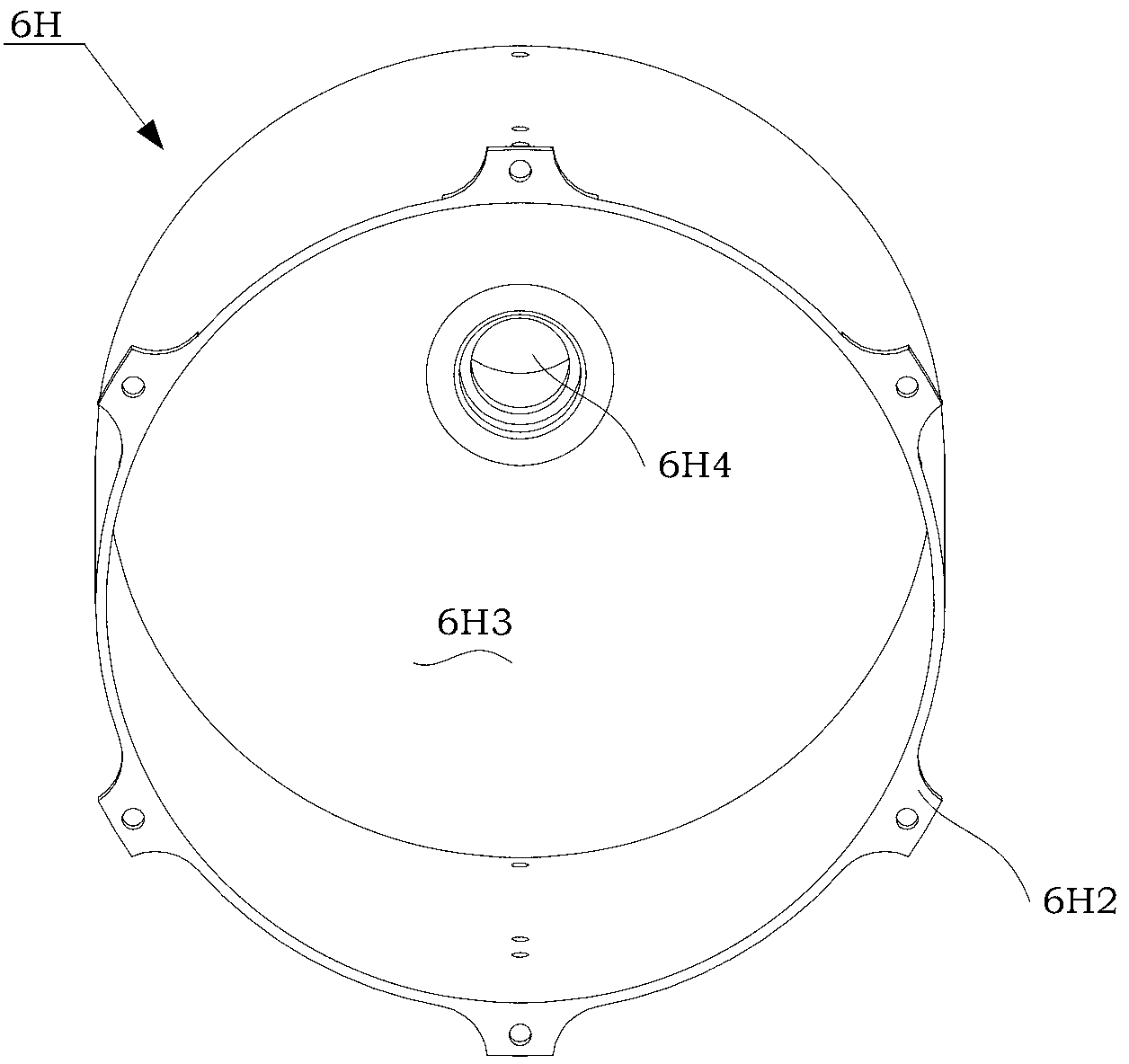

Erection girder body suitable for sea and air across amphibious unmanned aerial vehicle

ActiveCN103171754AKeep the shape of the whole machineMake the transitionFuselagesMarine engineeringFuselage

The invention discloses an erection girder body suitable for a sea and air across amphibious unmanned aerial vehicle. The body comprises a first supporting rod, a second supporting rod, a third supporting rod, a fourth supporting rod, a first fixing plate, a second fixing plate, a third fixing plate, an erection girder shell, a supporting rod connecting disc and an erection girder outer sleeve, wherein the first supporting rod, the second supporting rod, the third supporting rod and the fourth supporting rod are supported through the first fixing plate and the second fixing plate which are arranged in parallel; the third fixing plate is arranged between the first fixing plate and the second fixing plate; the erection girder shell and the supporting rod connecting disc are connected through matching between the screw and the nut assembled in a lug; and one end of the erection girder outer sleeve is connected to the front end of the erection girder shell. The body has the rod piece structure, so that a sealing outer sleeve is not independently designed on the outer side, and when the unmanned aerial vehicle enters a water environment, gaps among various rod pieces can be rapidly filled with water, so that the average density of the unmanned aerial vehicle body is close to the density of water in a short time, and transition of the unmanned aerial vehicle from an air environment to a water environment is realized.

Owner:北京华信智航科技有限公司

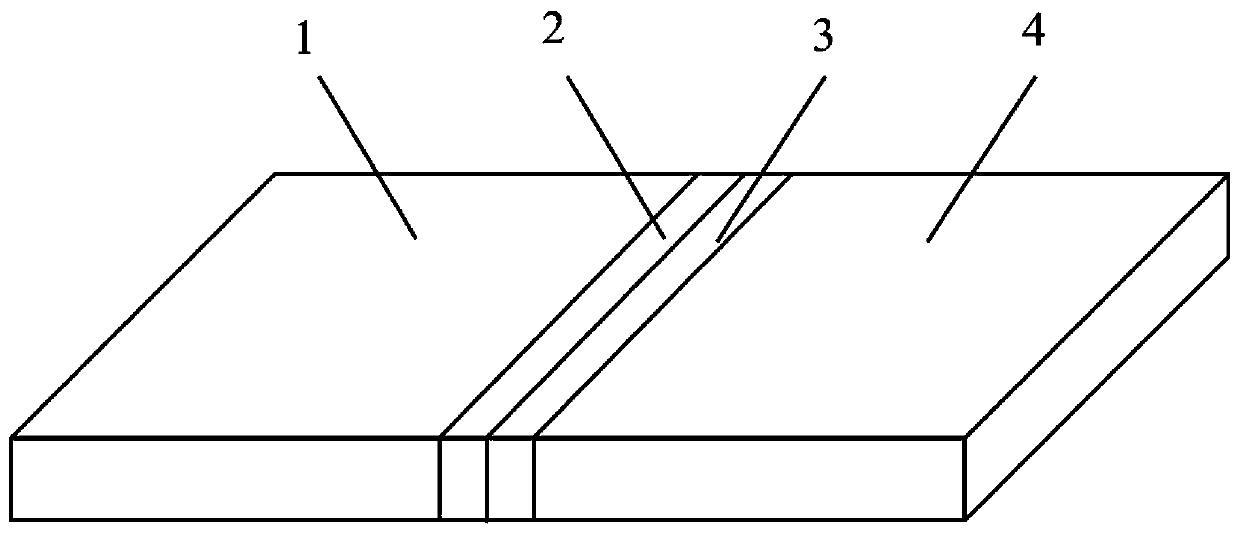

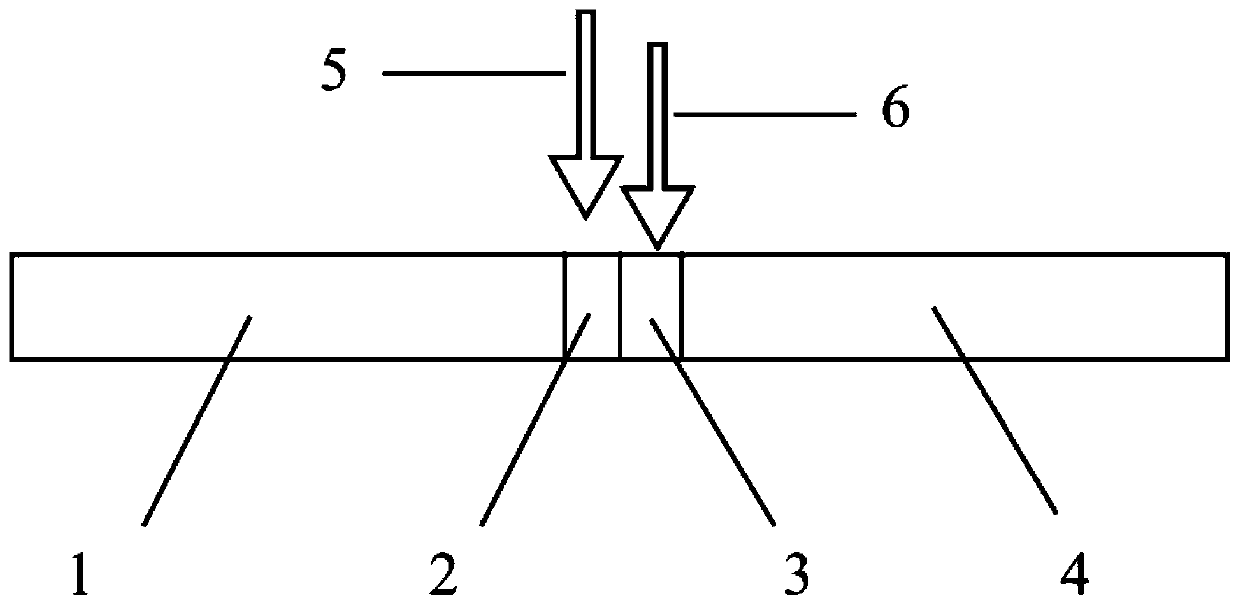

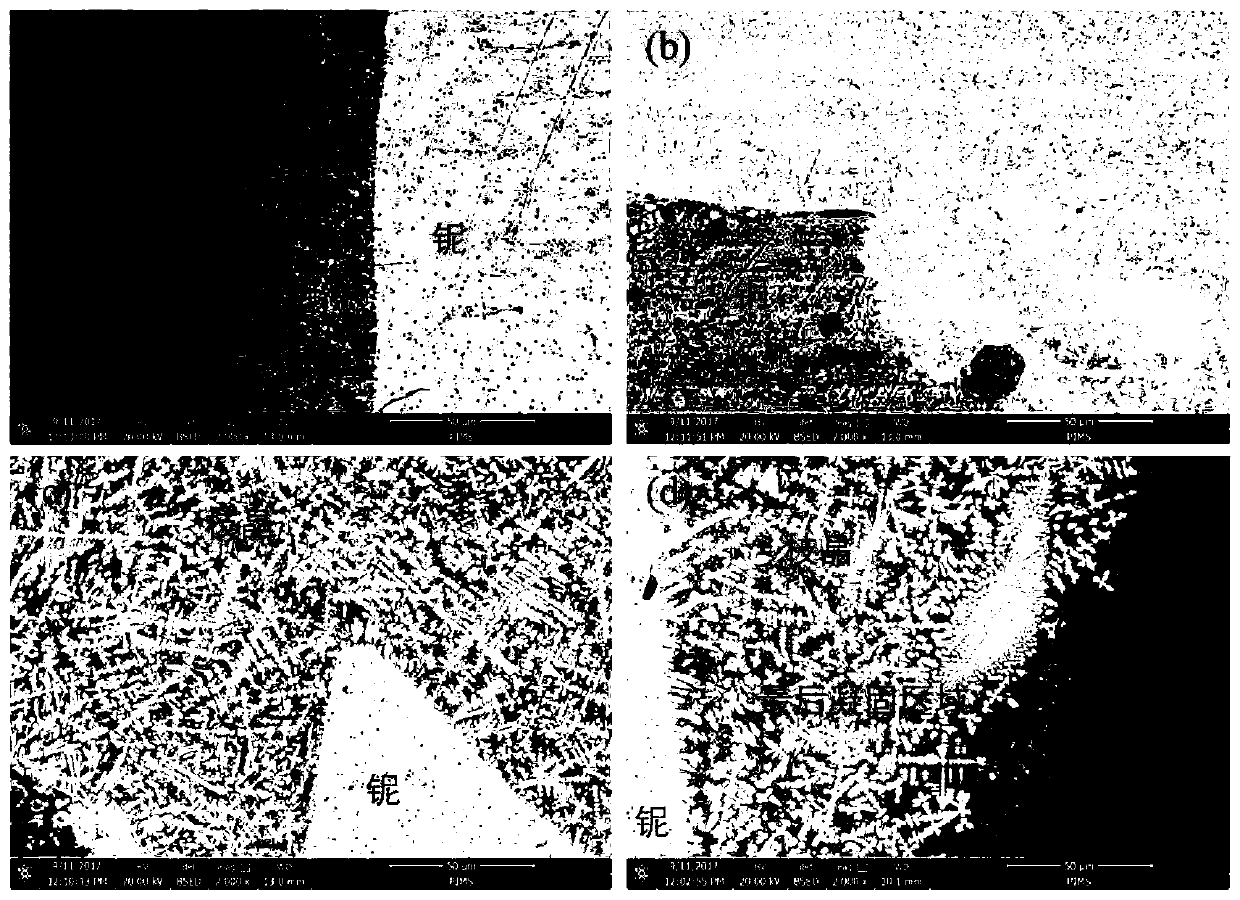

Titanium alloy and stainless steel dissimilar vacuum electronic beam welding method

InactiveCN111299795AAvoid generatingSuppress generationElectron beam welding apparatusWelding/soldering/cutting articlesMolten bathMetallic materials

The invention discloses a titanium alloy and stainless steel dissimilar vacuum electronic beam welding method, and belongs to the technical field of metal material welding. The method mainly includesthe steps of: cleaning the surface to be welded of a sample; assembling the sample; and welding through an electronic beam welding technology. A copper and niobium compound sandwich layer is added between a TC4 titanium alloy and 316L stainless steel; the placement sequence is TC4 titanium alloy-niobium foil-copper foil-316L stainless steel or 316L stainless steel-copper foil-niobium foil-TC4 titanium alloy; through selection of proper parameters such as electronic beam flow, acceleration voltage, welding speed and beam deviation distance and the thickness of the sandwich layer, a transition solid solution phase is formed in a welding line molten bath, so that the diffusion reaction among the elements such as titanium, iron and chromium is inhibited, formation of a brittle titanium and iron intermetallic compound is prevented to damage the performance of a welding line; and a welding joint obtained by the welding method is lower in hardness, higher in tensile strength and free of obvious defects such as air holes and cracks.

Owner:SOUTHWEST JIAOTONG UNIV

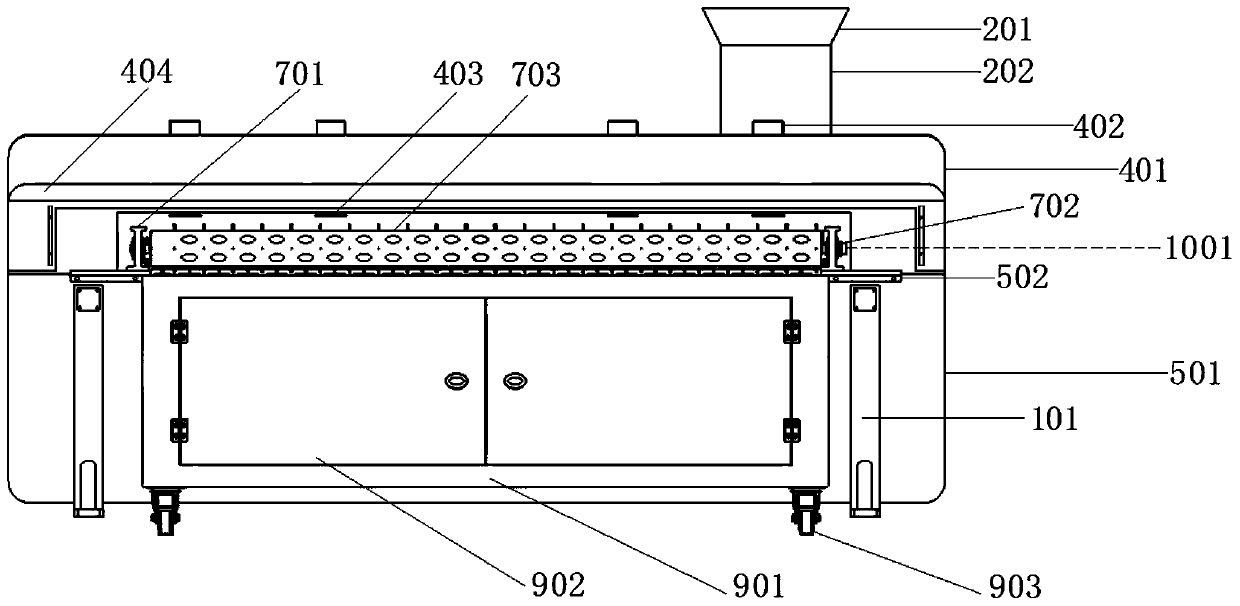

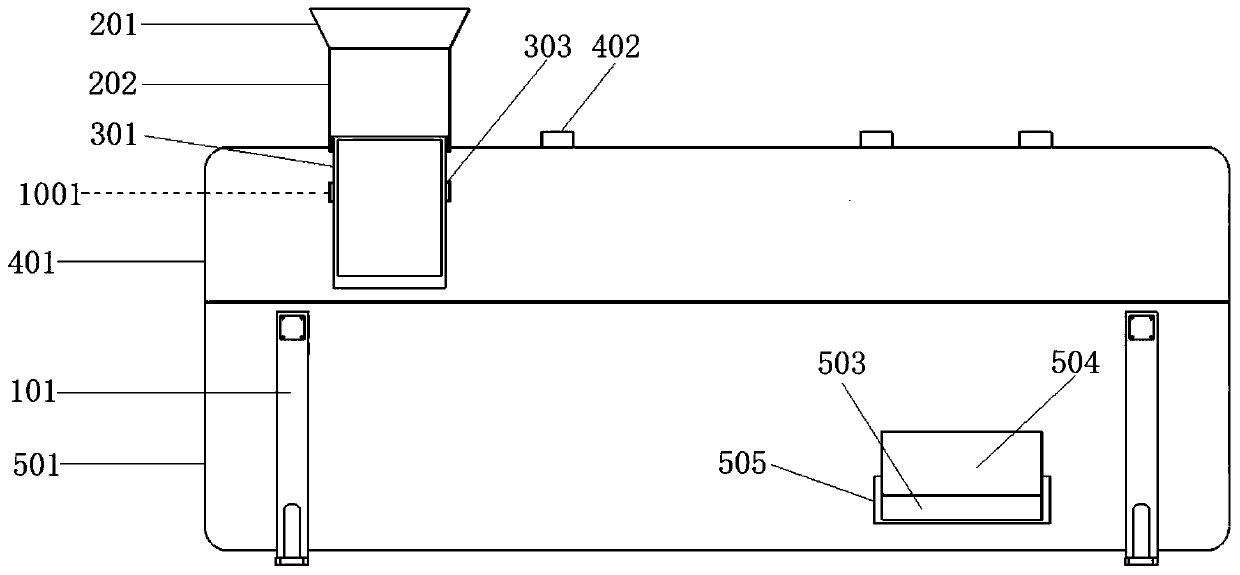

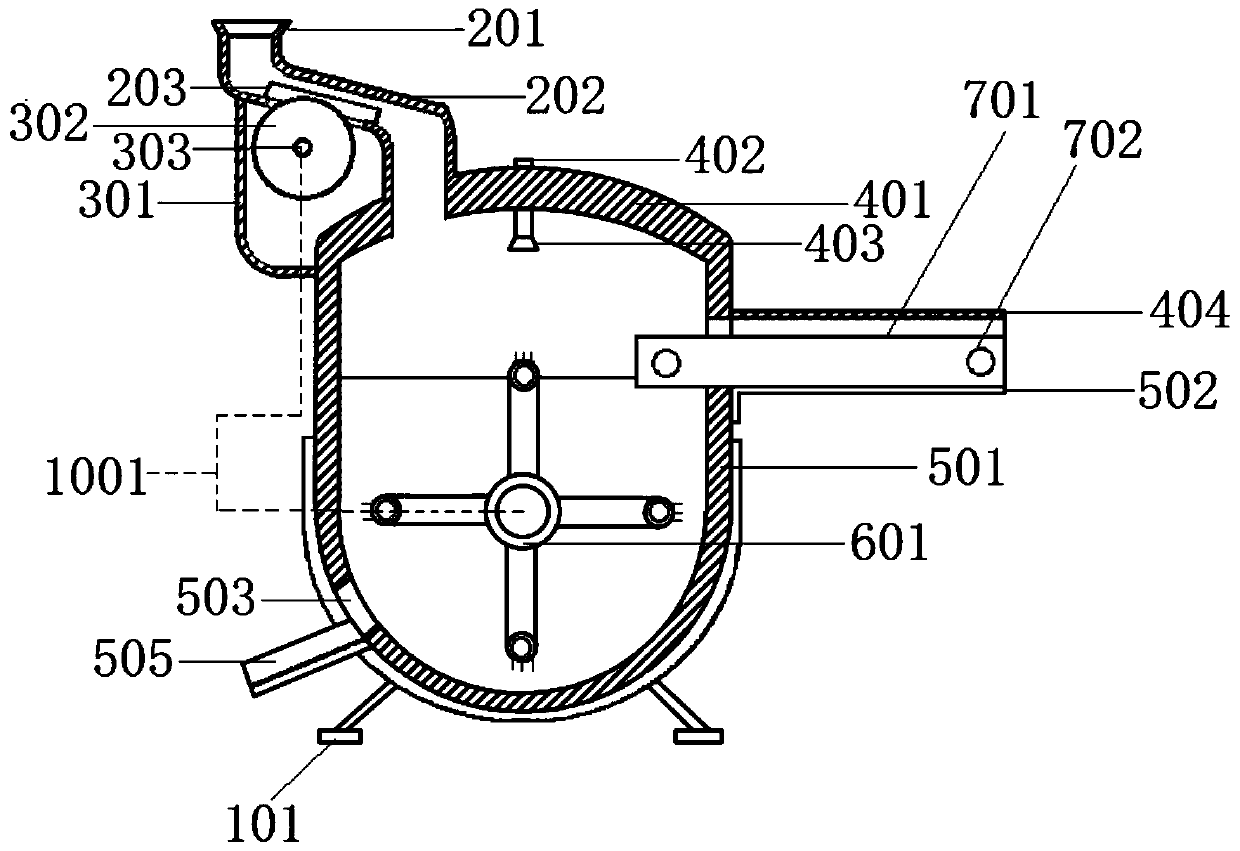

Plastic bag foreign matter continuous automatic sorting device for kitchen garbage

PendingCN111468523AReduce volumeEasy sorting operationTransportation and packagingSolid waste disposalForeign matterControl system

The invention provides a plastic bag foreign matter continuous automatic sorting device for kitchen garbage, and belongs to the field of waste recycling. The device comprises a rack, a feeding device,a pre-cutting device, an upper material bin, a lower material bin, a stirring and sorting device, a conveying device, a falling-down object taking device, a collecting bin and a driving and control system. The plastic bag foreign matter continuous automatic sorting device for the kitchen garbage has the beneficial effects that sorting of plastic bags mixed in the kitchen garbage can be automatically completed, compared with existing manual sorting, the labor cost can be reduced, the working efficiency can be improved, the quality of recycled products can be effectively improved, generation ofharmful substances can be reduced, and the device is suitable for the pretreatment stage of kitchen garbage reutilization.

Owner:BEIJING TECHNOLOGY AND BUSINESS UNIVERSITY

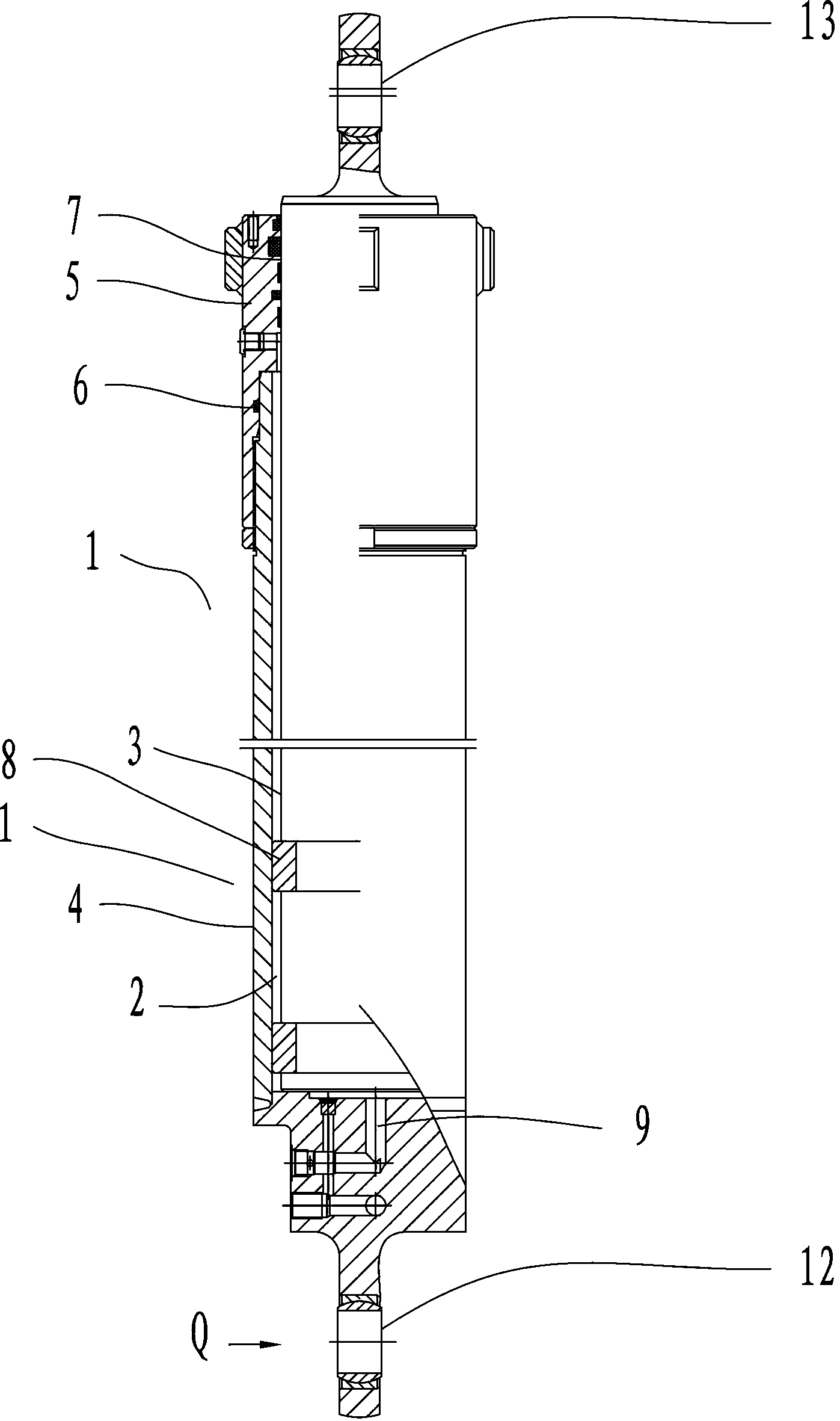

Solenoid valve and driver assistance device comprising said type of solenoid valve

InactiveCN102712307AMake the transitionImplementation orientationOperating means/releasing devices for valvesMagnetsDriver/operatorSolenoid valve

The invention relates to a solenoid valve comprising an armature (1) which is arranged in the region of at least one magnetic coil. At least one radial recess (6, 10) extending essentially in the radial direction, traversing at least in parts the front surface (2) of the armature (1) is provided. The invention also relates to a driver assistance device comprising said type of solenoid valve.

Owner:ROBERT BOSCH GMBH

Special fixture and method for mounting core pipe of OVD sintering quartz furnace

The invention provides a special fixture and method for mounting a core pipe of an OVD sintering quartz furnace. The fixture comprises a connection top plate and a hoisting component and an adjusting component arranged on the connection top plate, wherein the hoisting component comprises a left ring device, a middle ring device and a right ring device arranged on the connection top plate in an equal interval; the adjusting component comprises multiple adjusting devices uniformly arranged along the outer circumference of the connection top plate; the adjusting device comprises a radial adjusting plate mounted on the connection top plate through a first connector and an axial adjusting plate mounted on the radial adjusting plate through a second connector; a connection top plate buffer pad is arranged on the lower side of the connection top plate; and an axial adjusting plate buffer pad is arranged on the axial adjusting plate. The fixture provided by the invention has an adjustment function along the axial and radial directions of the core pipe of the quartz furnace; and since a buffer pad is fixed on the part in contact with the core pipe of the quartz furnace, direct contact between metal and the core pipe of the quartz furnace is avoided, and the core pipe of the quartz furnace is prevented from cracking under impact force in a hoisting process.

Owner:TONGDING INTERCONNECTION INFORMATION CO LTD +1

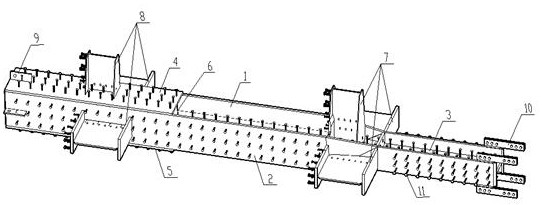

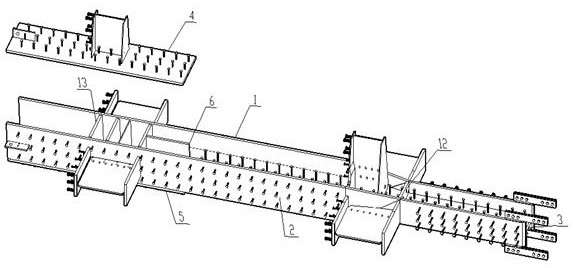

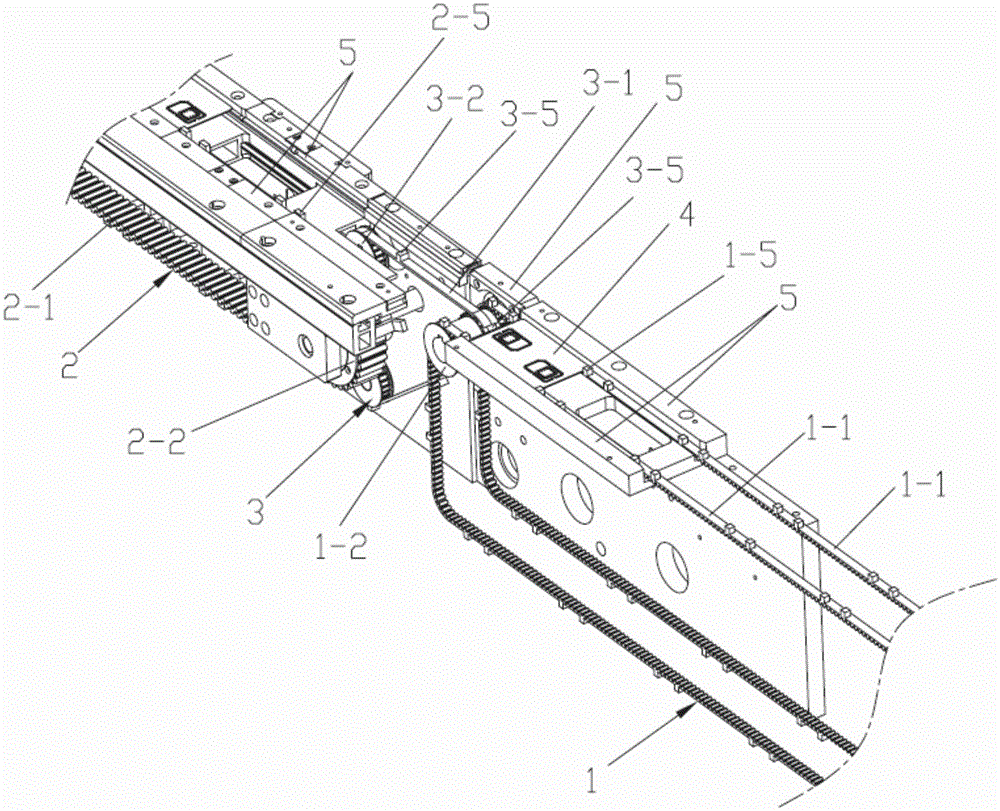

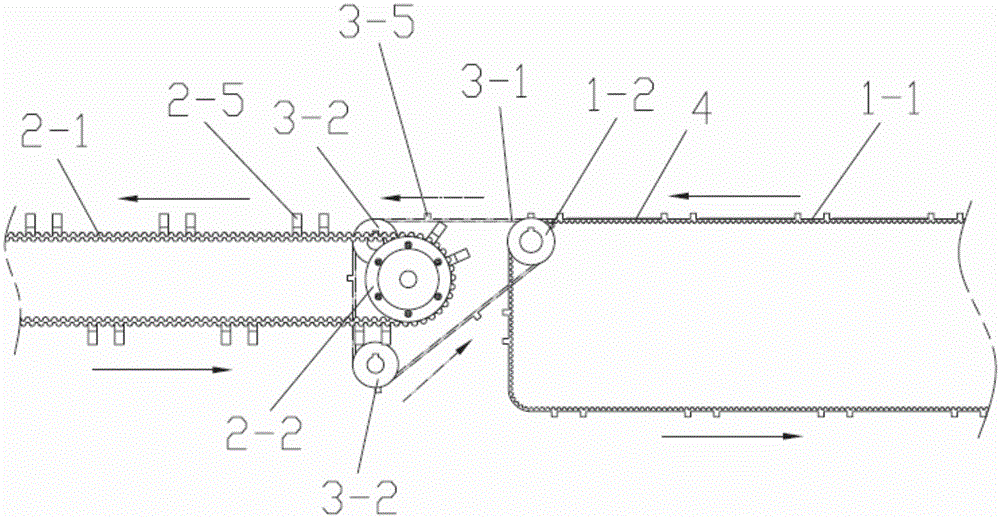

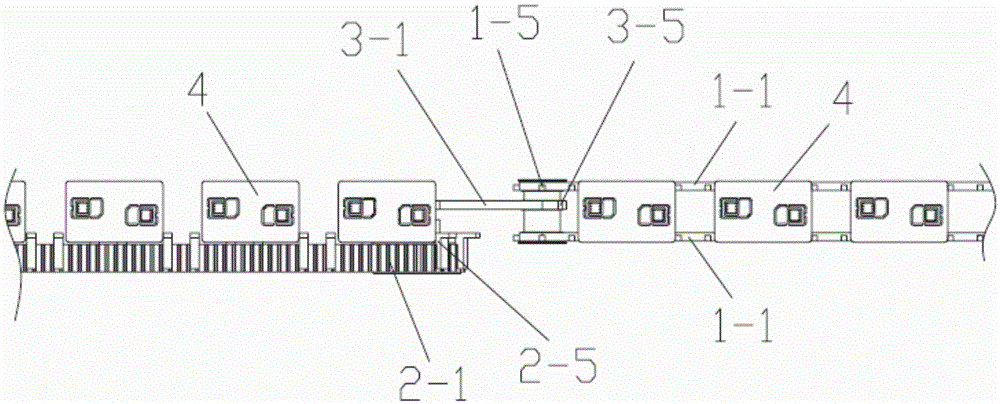

Transition device and transition method of smart card conveying mechanisms

ActiveCN105151639AIncrease productivityReduce labor costsConveyorsConveyor partsEngineeringMechanical engineering

The invention discloses a transition device and transition method of smart card conveying mechanisms. The transition device comprises a transition mechanism arranged between the first card conveying mechanism and the second card conveying mechanism. Each of the first card conveying mechanism, the second card conveying mechanism and the transition mechanism comprises a synchronous conveying belt and a power mechanism. A plurality of sets of thumbing teeth are uniformly arranged on each synchronous conveying belt; a first transition conveying position and a second transition conveying position are arranged at the work part of the transition synchronous conveying belt; the last conveying position on the work part of the first synchronous conveying belt coincides with the first transition conveying position; the first conveying position on the work part of the second synchronous conveying belt coincides with the second transition conveying position. According to the invention, two processing devices can be combined in work to achieve coordinated transition, coherent transition of cards can be achieved, the production efficiency can be improved, and the manual cost can be lowered.

Owner:惠州市众宏通智能卡有限公司

SDN-based Ethernet ip packet encapsulation method and network isolation and dhcp implementation method

ActiveCN104010049BIncrease contentIncrease the proportionData switching networksPhysical layer packetNetwork isolation

The present invention proposes an SDN-based Ethernet IP packet encapsulation method and network isolation and DHCP implementation method, which solves the above-mentioned technical problems such as complex forwarding process and reduced transmission efficiency caused by packet layer 2 header encapsulation. Step 1, the physical layer of the device obtains physical signals from the transmission medium according to the frame gap and the guide frame, and converts the physical signals into bits, and sends them to the data link layer; Step 2, the data link layer performs MAC address identification and addressing; Step 3, analyze the protocol stack to identify the message; Step 4, transfer the route to the data link layer to perform other processing procedures except Ethernet encapsulation and MAC addressing, according to The message header format is passed to the physical layer for processing; step 5, the physical layer converts the bits of the message data frame into photoelectric signals according to the original method and forwards them.

Owner:EAYUN INC

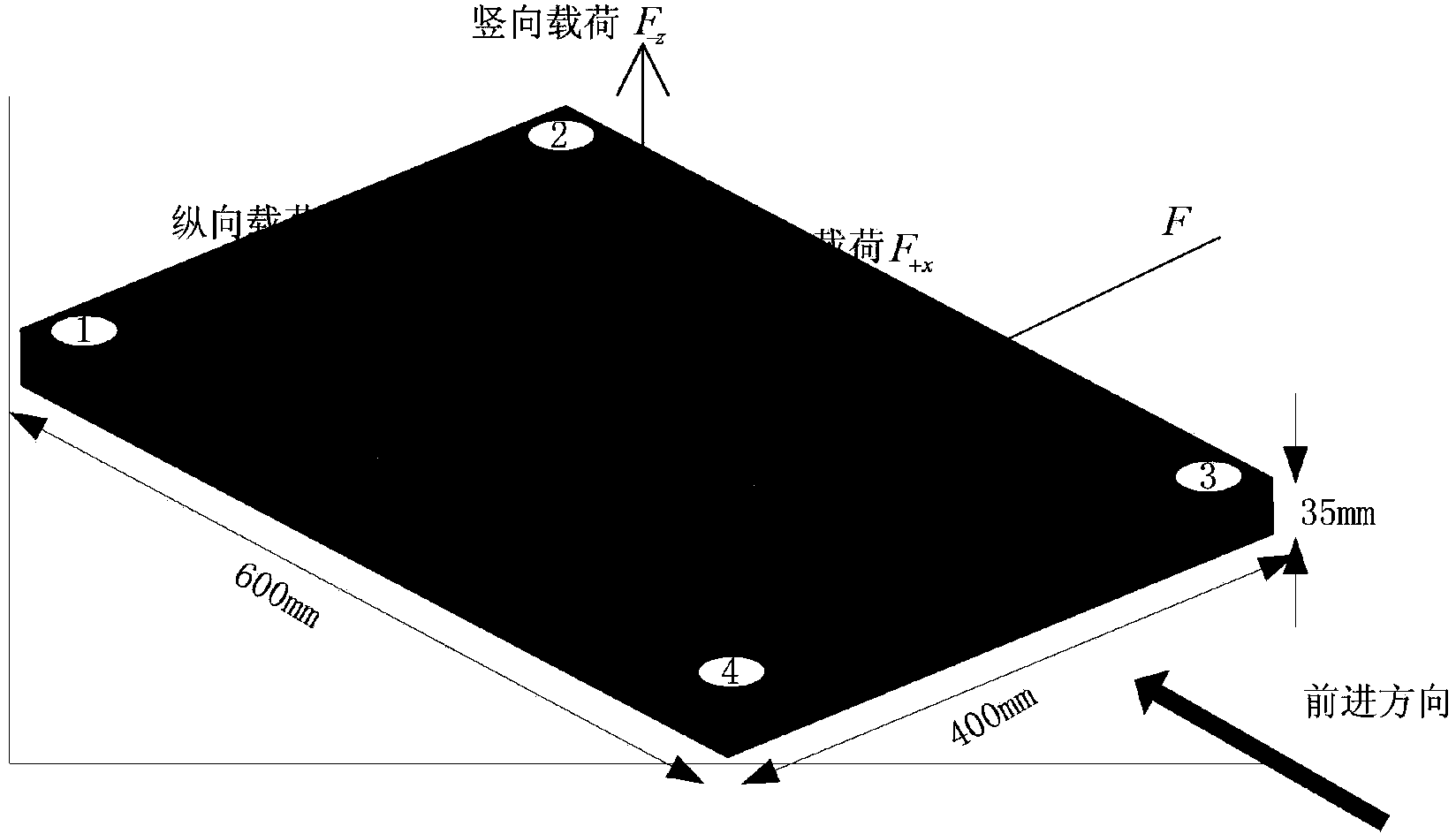

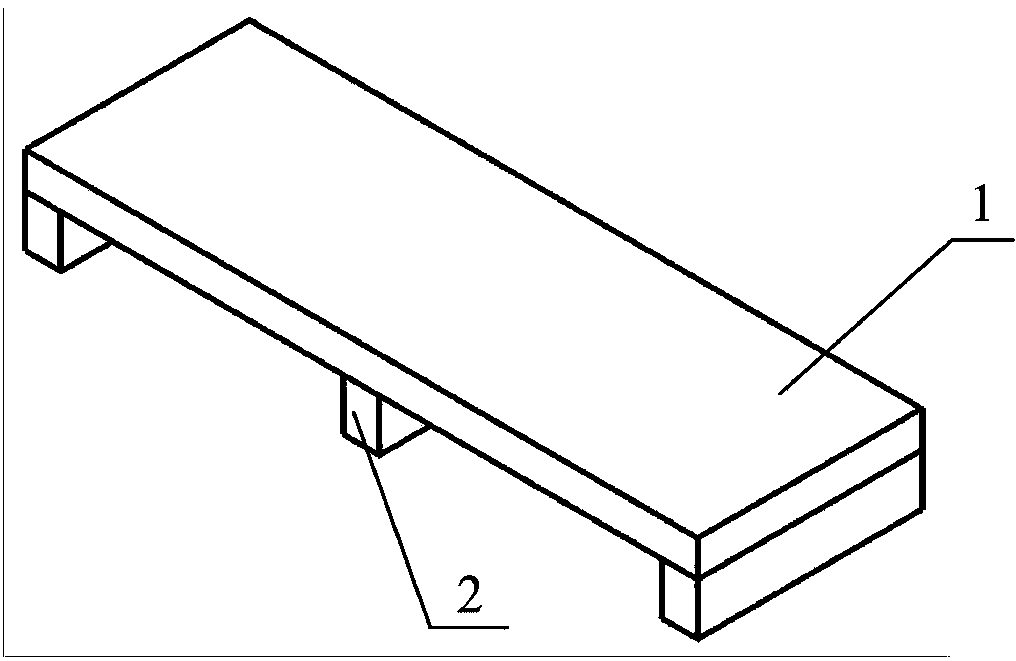

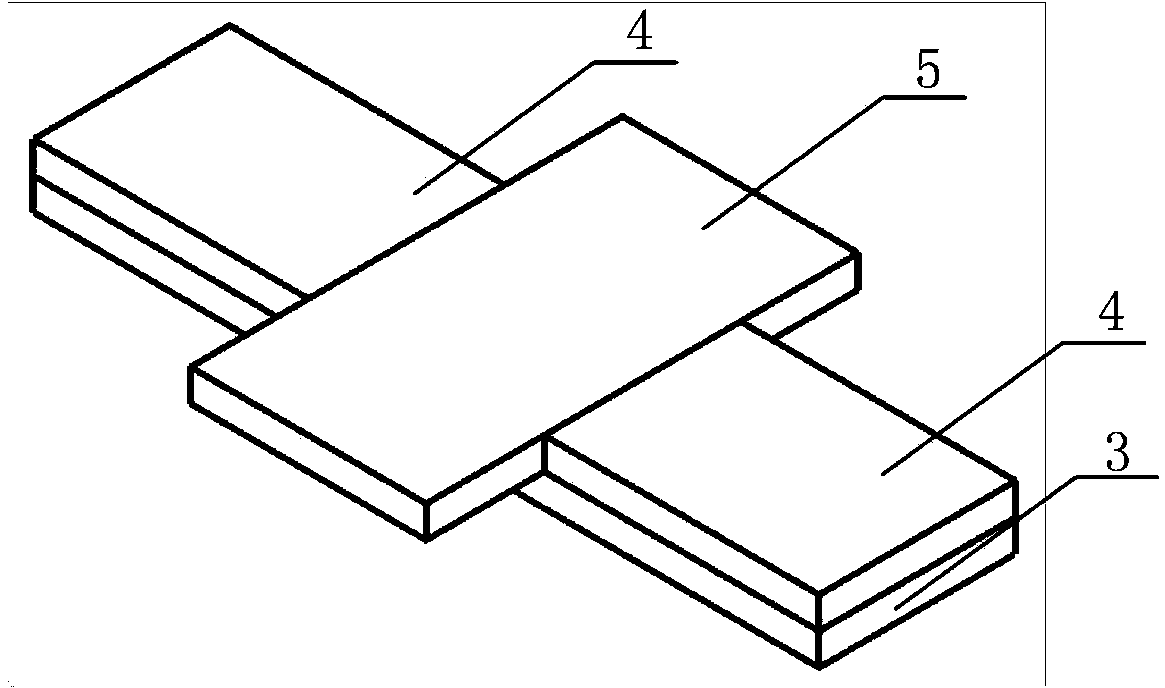

Human-induced load testing system based on force measurement plate

InactiveCN103954393AMake the transitionThe test result is accurateMeasurement of force componentsData processing systemBiomechanics

The invention relates to a human-induced load testing system based on a force measurement plate and belongs to the field of biomechanics. The human-induced load testing system comprises a detection system, a pedestrian path and a data processing system. The detection system is the force measurement plate. The pedestrian path comprises a leading-in channel, a testing platform, a leading-out channel and counter weights. The leading-in channel and the leading-out channel are located on two sides of the testing platform, a leading-in plate, a test plate, a bearing plate and a leading-out plate are required to be located on the same horizontal plane. The counter weights are symmetrically arranged on two sides of the bearing plate. The force measurement plate is put under a base plate central point. The data processing system acquires data through the detection system. The human-induced load testing system closely re-shows and tests various advancing modes (walking, stepping, running, jumping and the like) of people on a horizontal plane in a natural state mode.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

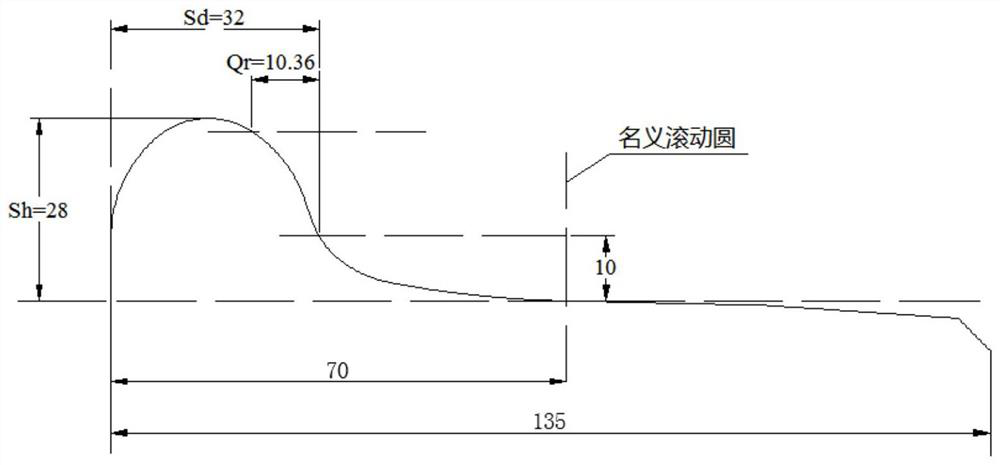

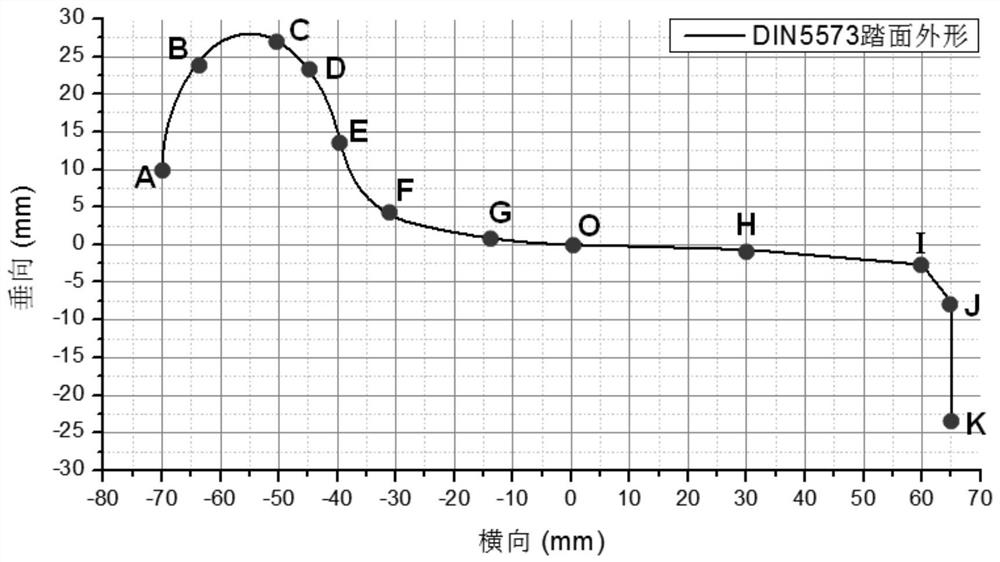

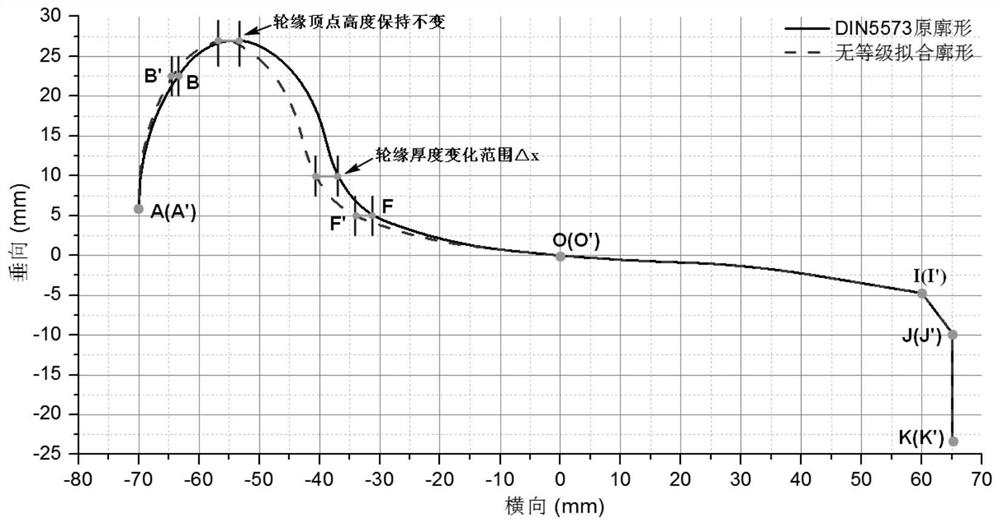

Stepless turning repair method for DIN5573 type subway wheel

PendingCN113806883AEconomicalLower rim heightGeometric CADDesign optimisation/simulationStructural engineeringControl theory

The invention discloses a stepless turning repair method for a DIN5573 type subway wheel, and belongs to the technical field of wheel turning repair strategies. The method the following steps of: 1, measuring and obtaining an actually-measured tread profile curve of the DIN5573 type wheel, and obtaining coordinate information of each key point in the actually-measured tread profile curve; 2, respectively constructing a corresponding abscissa change rate model for the initial coordinate and the end point coordinate of each section to obtain changed key point coordinate information; 3, constructing a nine-order fitting curve model for each section, and performing fitting to form a fitting tread profile curve in combination with the changed initial coordinates and end point coordinates of the corresponding section, so as to form a grade-free fitting tread profile; and 4, carrying out turning repair on the DIN5573 type wheel according to the stepless fitting tread profile. According to the method, the tread profile closest to the actual profile is generated in real time based on the actually measured rim thickness, stepless turning repair of the DIN5573 type tread is truly achieved, good economical efficiency is achieved, the service life of the wheel can be effectively prolonged, and the operation cost can be effectively reduced.

Owner:CRRC NANJING PUZHEN CO LTD

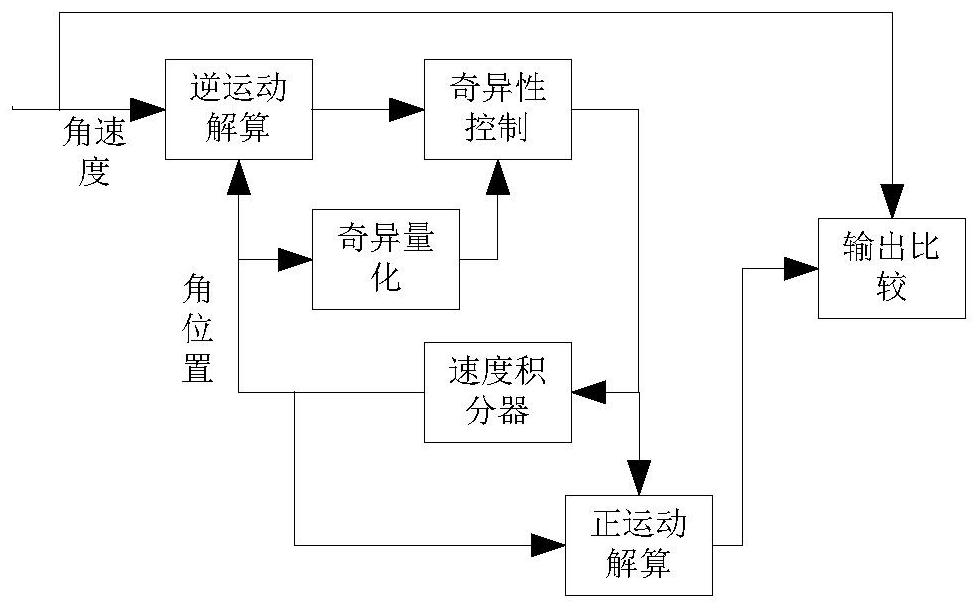

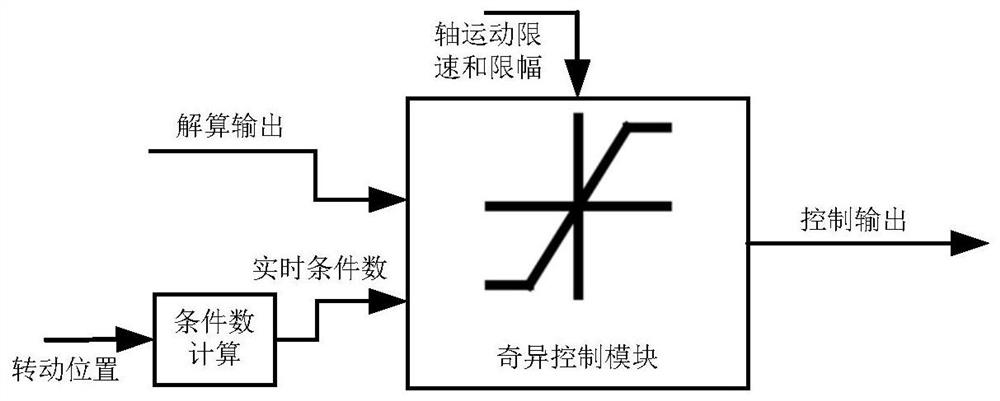

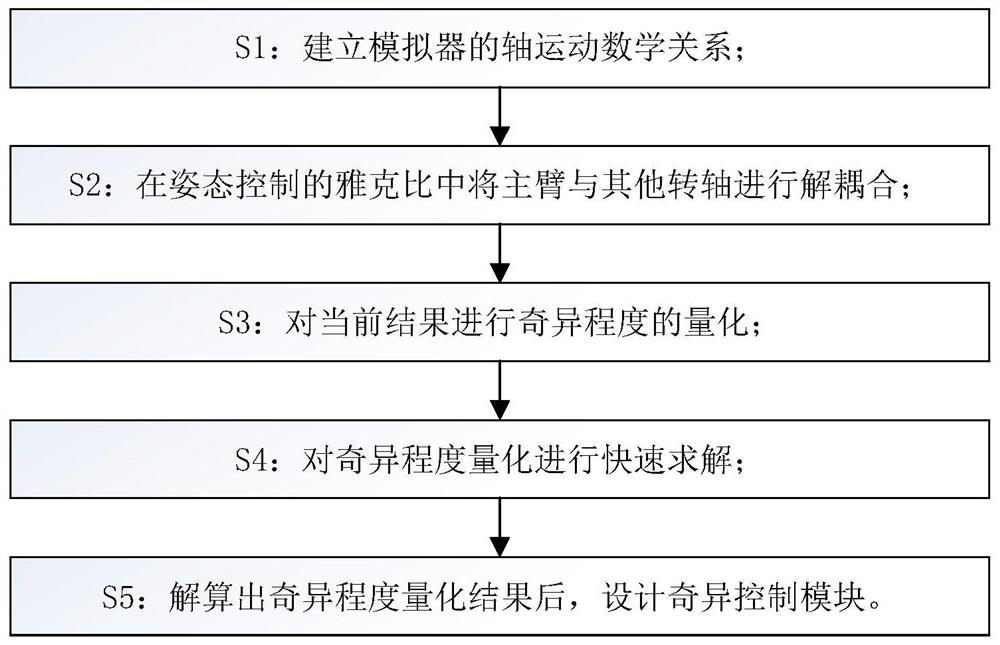

Multi-axis coupling motion singularity control method for continuous load simulator

ActiveCN111813139AAvoid Mutation SituationsImprove stabilityAttitude controlPosition/course control in three dimensionsAttitude controlSimulation

The invention discloses a multi-axis coupling motion singularity control method for a continuous load simulator. The method comprises the following steps: S1, establishing an axis motion mathematicalrelationship of the simulator; S2, decoupling the main arm from other rotating shafts in the Jacobian of attitude control; S3, quantifying the singular degree of the current result; S4, carrying out quick solving on the quantification of the singular degree; and S5, after a singular degree quantification result is solved, designing a singular control module. According to the method, singular pointtransition is carried out under the condition that the shaft motion stroke is fully utilized; and the sudden change of the vicinity of the singular point due to the limitation of the mechanical rangeof the shaft is avoided in a mode of reducing the proportion of the control instruction, so that the stability and fidelity of flight simulation are improved.

Owner:GENERAL ENG RES INST CHINA ACAD OF ENG PHYSICS

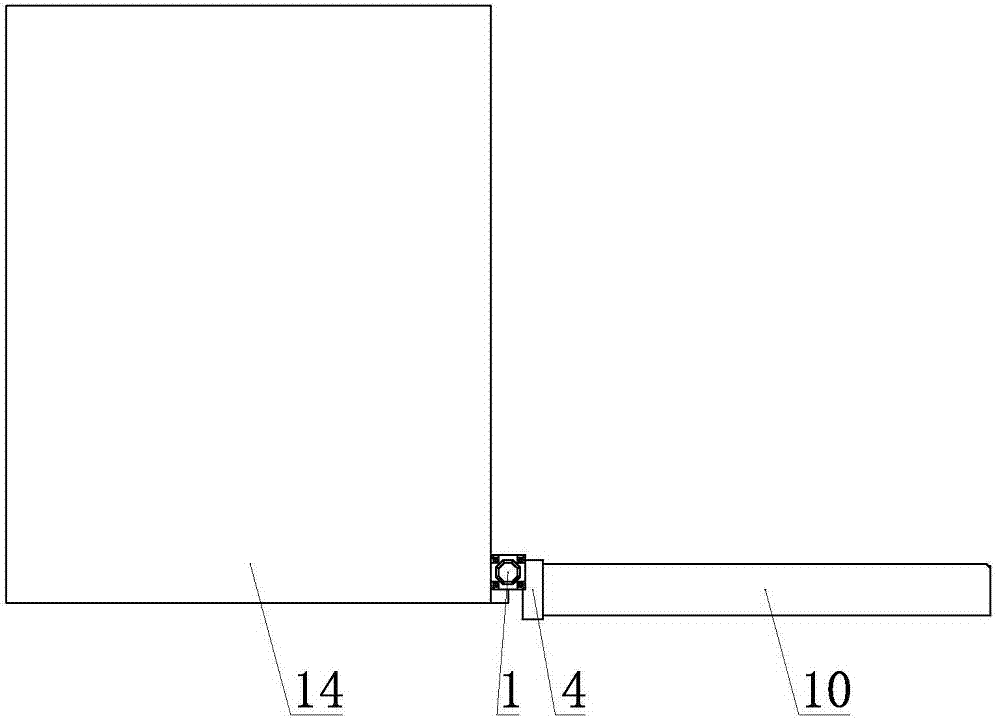

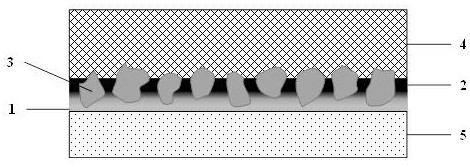

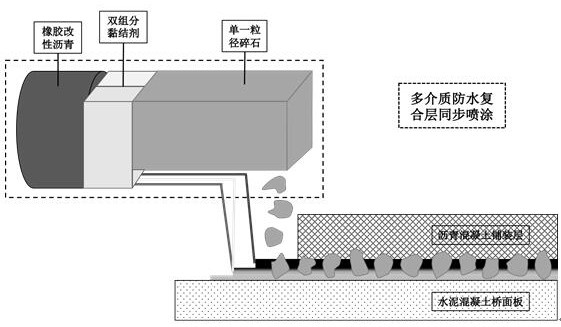

Long-life cement concrete bridge multi-medium waterproof composite layer

PendingCN114351579ARealize simultaneous high-pressure sprayingHigh strengthBridge structural detailsBridge erection/assemblyBridge deckStructural engineering

A long-service-life cement concrete bridge multi-medium waterproof composite layer is characterized in that a waterproof bonding composite layer is sequentially composed of a bi-component adhesive layer and a rubber modified asphalt layer outwards along a bridge floor, single-particle-size broken stones are inserted between the bi-component adhesive layer and the rubber modified asphalt layer in a penetrating mode, the bi-component adhesive layer is formed by bi-component bonding materials, and the rubber modified asphalt layer is formed by the bi-component bonding materials. The rubber modified asphalt layer is formed by rubber modified asphalt, the rubber modified asphalt layer, the bi-component bonding material, the rubber modified asphalt and the single-particle-size gravel are constructed synchronously, and according to the spreading amount, the content of the bi-component bonding material is 1.0-1.5 kg / m < 2 >, the content of the rubber modified asphalt is 1.6-2.0 kg / m < 2 >, and the coverage rate of the single-particle-size gravel is 60-70%. The waterproof composite layer material disclosed by the invention has outstanding waterproofness, durability, bonding strength and shearing strength, and can be well applied to bridge deck pavement of a cement concrete bridge, so that the service life of the concrete bridge deck is prolonged.

Owner:SOUTHEAST UNIV

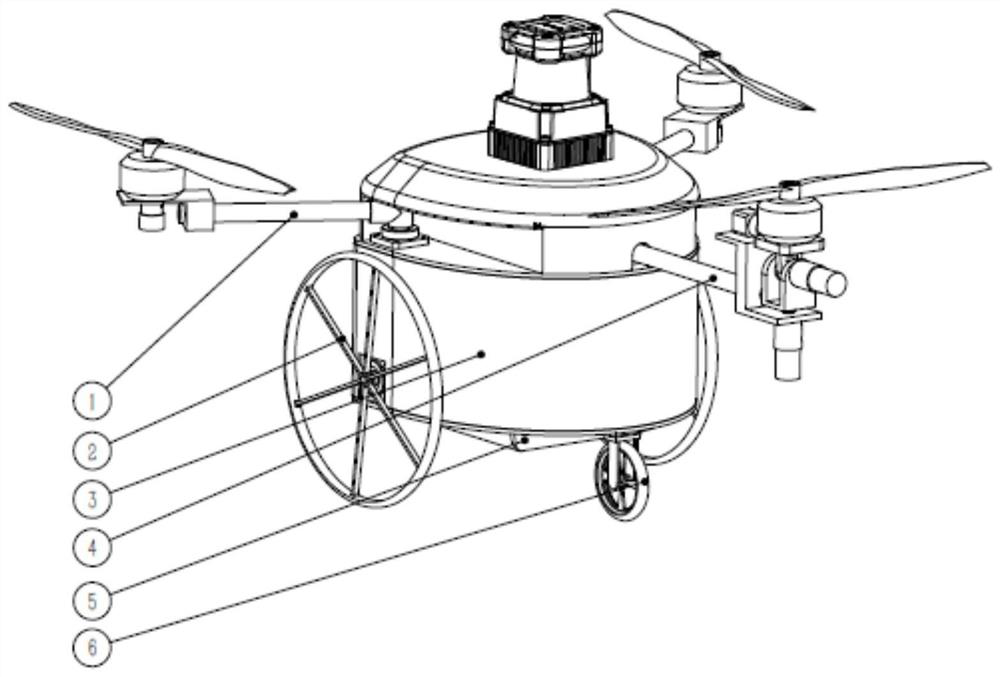

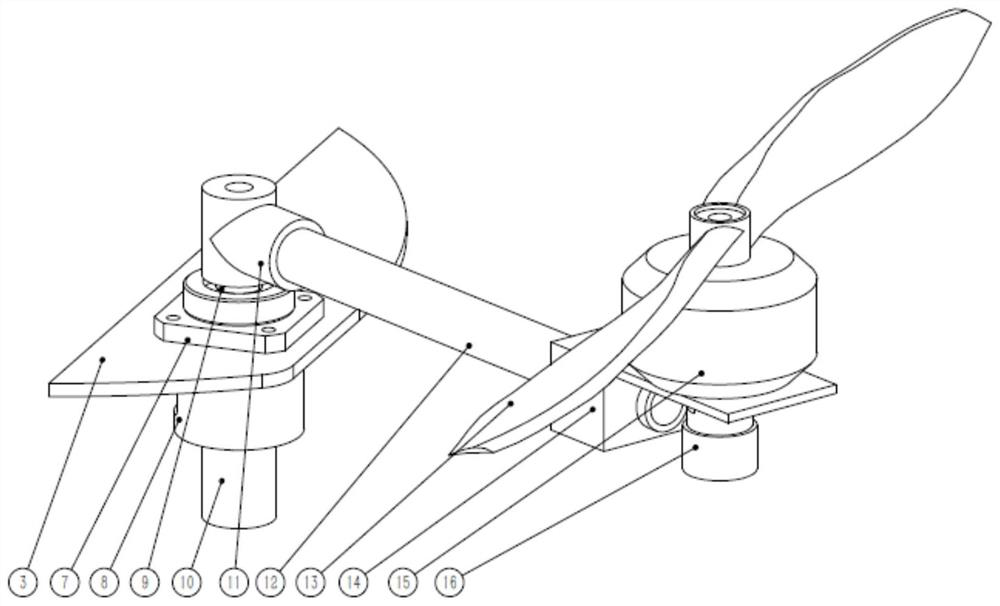

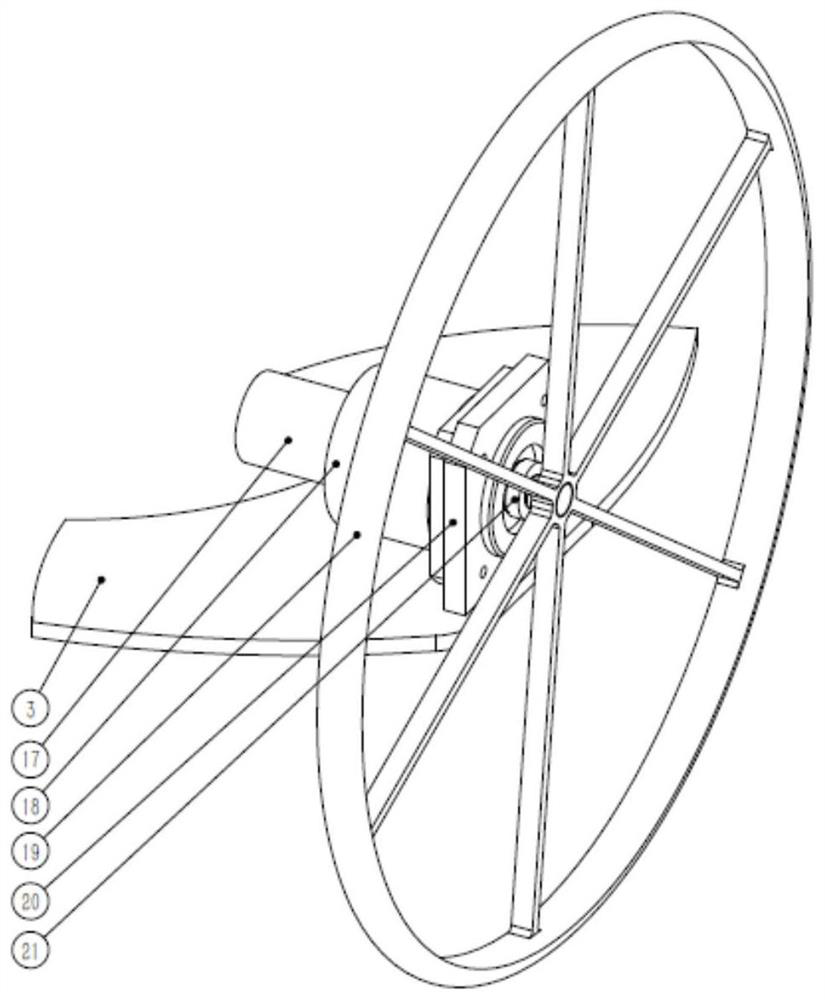

A three-rotor wheeled amphibious robot

ActiveCN108638773BOvercome limitationsMake the transitionConvertible vehiclesDrive wheelControl system

The invention discloses a three-rotor wheel type amphibious robot for land, water and air. The robot includes a rotary wing assembly, a driving wheel assembly, a body, an adjusting wing assembly, a pressure regulating assembly, a universal wheel, a control system and a sensor; the rotating wing assembly and the adjusting wing assembly are all installed on the body; the driving wheel assembly is installed on The left and right sides of the body; the pressure regulating component is installed at the bottom of the body to adjust the buoyancy by controlling the volume change of the body; the universal wheel is set at the end of the body; the control system and various sensors are installed on the body for Environmental acquisition and control; in ground mode, two rotors of the trirotor are automatically folded, and the other rotor provides ground auxiliary traction through variable structure; in water mode, the diving depth is controlled by the pressure regulating component and two of the rotors; Rotor and two steering gears realize air flight. The invention can move in different habitat environments in the air, on the ground and in the water, and can realize the transition of cross-domain environments.

Owner:NANJING UNIV OF SCI & TECH

A Method for Rapid Transition of Finite Element 3D Model Mesh

ActiveCN103530463BReduce the totalImprove efficiencySpecial data processing applicationsElement modelProximal point

The invention discloses a method for quick transition of finite element three-dimensional model grids, relates to a method for finite element model grid transition and aims at solving the problem that an existing grid transition method is only limited to a single-direction transition means, namely, in the single direction, the grid size proportion of a far end and a short end is 2 or 3 and is used as the transition proportion to conduct multiple times of grid transition, and the means can not realize the finite element simulation of large components. The method comprises the steps of dividing a component into an important area, a transition area and a non-important area according to the size of calculation data change gradient of different parts of the component; dividing the important area into a plurality of grids in a shape of a cube or a cuboid, wherein grids in the important area A should be dense; conducting transition grid division on the transition area; dividing the non-important area into a plurality of grids in a shape of a cube or a cuboid, wherein grids in the non-important area should be sparse. Consequently, the grid division of the whole component is finished. The method is used for grid division of finite element model simulation modeling of a large or super large component.

Owner:HEILONGJIANG INST OF TECH

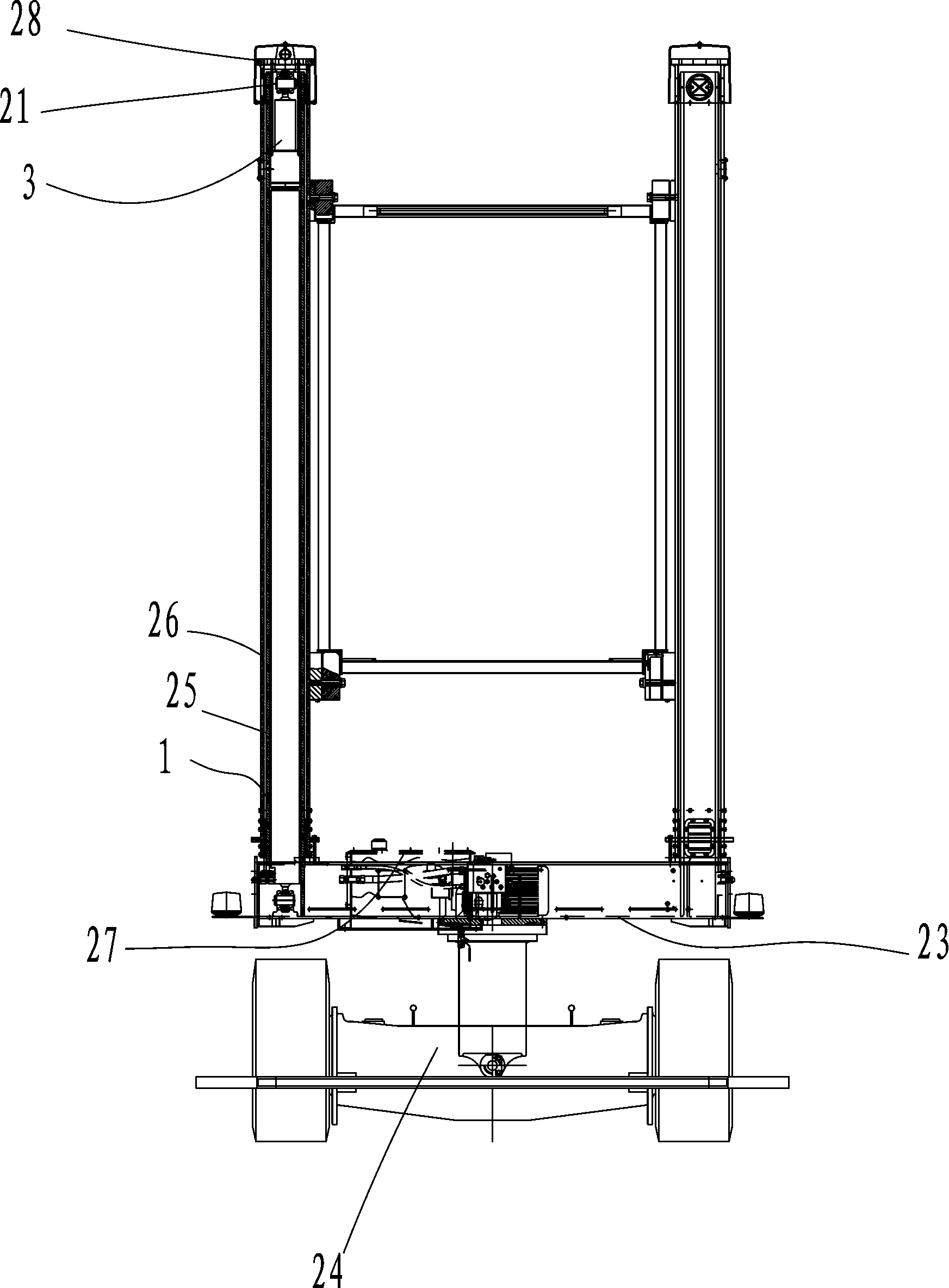

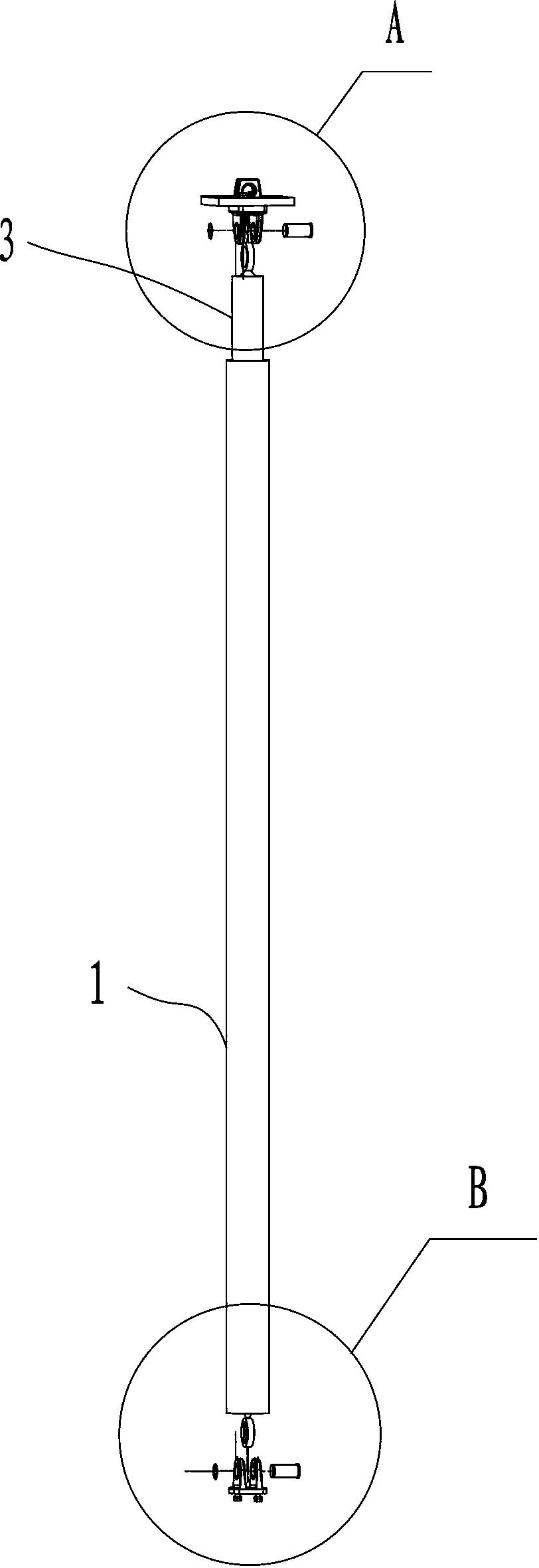

Boarding bridge lifting device

The invention discloses a boarding bridge lifting device comprising a beam and an inner guide pipe, wherein a locating hole is relatively formed in the beam; the inner guide pipe is inserted into the beam via the locating hole; the inner guide pipe is welded with the beam; a plunger type hydraulic cylinder is arranged in the inner guide pipe; an outer guide pipe capable of sliding up and down is sleeved on the inner guide pipe; the outer guide pipe is connected with the plunger type hydraulic cylinder by an upper fixing seat; the hydraulic cylinder is connected with the beam by a lower fixing seat; a hydraulic power device is arranged on the beam; and the plunger type hydraulic cylinder is driven by the hydraulic power device.

Owner:THYSSENKRUPP AIRPORT SYSTEM (ZHONGSHAN) CO LTD

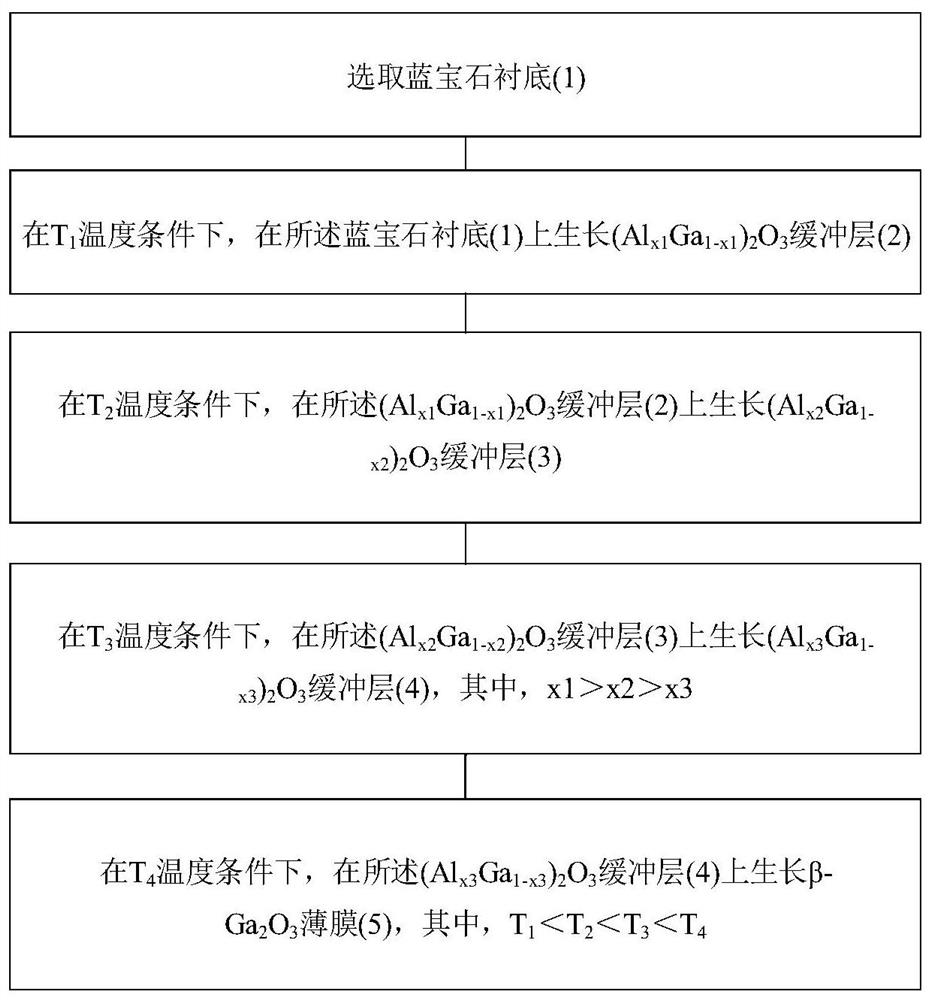

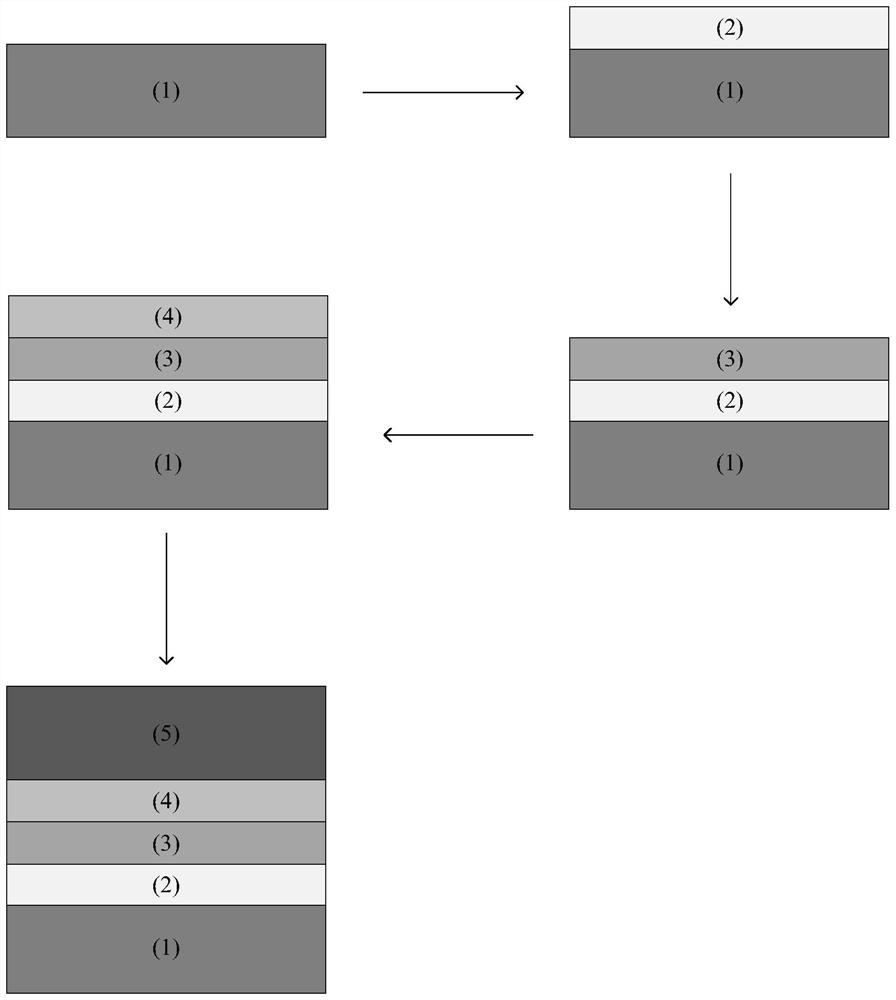

Growth method of beta-Ga2O3 film

PendingCN113571404AEnhanced two-dimensional growthReduce surface roughnessSemiconductor/solid-state device manufacturingLattice mismatchThin membrane

The invention relates to a growth method of a beta-Ga2O3 film. The growth method comprises the following steps of selecting a sapphire substrate; growing a (Alx1Ga1-x1)2O3 buffer layer on the sapphire substrate under a T1 temperature condition; under a T2 temperature condition, growing a (Alx2Ga1-x2)2O3 buffer layer on the (Alx1Ga1-x1)2O3 buffer layer; under a T3 temperature condition, growing a (Alx3Ga1-x3)2O3 buffer layer on the (Alx2Ga1-x2)2O3 buffer layer, wherein x1> x2> x3; and under a T4 temperature condition, growing the beta-Ga2O3 film grows on the (Alx3Ga1-x3)2O3 buffer layer , and T1<T2<T3<T4. According to the invention, the (Al1-xGax) 2O3 buffer layer growing at variable temperature is introduced between the beta-Ga2O3 film and the sapphire substrate, and the introduction of the (Al1-xGax) 2O3 buffer layer not only realizes the uniform transition of element components between the substrate and the film, but also realizes the transition of a lattice structure, so that the dislocation caused by the lattice mismatch is reduced. According to different element components among the buffer layers, different growth temperatures are adopted, so that the growth quality of the buffer layers is improved, the two-dimensional growth of the beta-Ga2O3 film is enhanced, and the surface roughness of the film is reduced.

Owner:XIDIAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com