Long-life cement concrete bridge multi-medium waterproof composite layer

A cement concrete and multi-media technology, applied in bridges, bridge parts, bridge materials, etc., can solve problems such as difficult to ensure the coordination of stress and strain, low bond strength, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

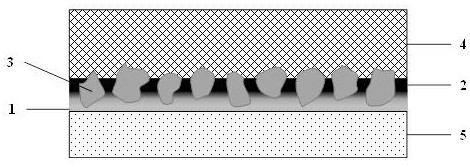

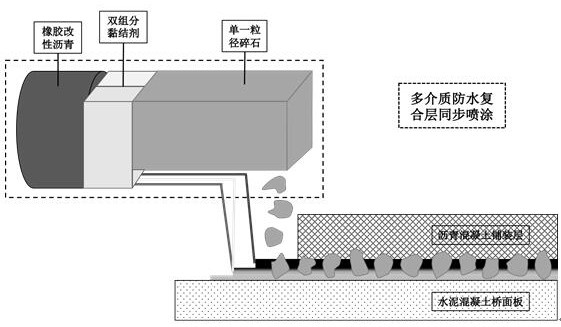

[0027] The three-component two-component binder, rubber-modified asphalt and single-size gravel used in the multi-media waterproof composite layer of the above-mentioned long-life cement concrete bridge are composed of simultaneous construction, and the content is as follows according to the amount of spreading:

[0028] Two-component binder 1.0kg / m 2 ;

[0029] Rubber modified asphalt 2.0kg / m 2 ;

[0030] Single particle size crushed stone 60% coverage.

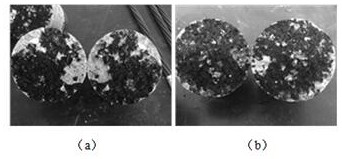

[0031] The two-component adhesive is a two-component epoxy resin adhesive, and the curing strength reaches more than 60% of the final strength within 30 minutes, and the final strength exceeds 10Mpa.

[0032] The two-component epoxy resin binder adopts bisphenol F type epoxy resin, which is Taiwan Nanya NPEF-170 bisphenol F type epoxy resin.

[0033] The rubber-modified asphalt is 40% waste tire rubber powder-modified asphalt with a softening point of not less than 75°C. It is purchased from Jiangsu Baoli Asphalt Company...

Embodiment 2

[0049] The three-component two-component binder, rubber-modified asphalt and single-size gravel used in the multi-media waterproof composite layer of the above-mentioned long-life cement concrete bridge are composed of simultaneous construction, and the content is as follows according to the amount of spreading:

[0050] Two-component binder 1.2kg / m 2 ;

[0051] Rubber modified asphalt 1.8kg / m 2 ;

[0052] Single particle size gravel 65% coverage.

[0053] The two-component adhesive is a two-component epoxy resin adhesive, and the curing strength reaches more than 60% of the final strength within 30 minutes, and the final strength exceeds 10Mpa.

[0054] The two-component epoxy resin binder adopts bisphenol F type epoxy resin, which is Taiwan Nanya NPEF-170 bisphenol F type epoxy resin.

[0055] The rubber-modified asphalt is 40% waste tire rubber powder-modified asphalt with a softening point of not less than 75°C. It is purchased from Jiangsu Baoli Asphalt Company and is...

Embodiment 3

[0071] The three-component two-component binder, rubber-modified asphalt and single-size gravel used in the multi-media waterproof composite layer of the above-mentioned long-life cement concrete bridge are composed of simultaneous construction, and the content is as follows according to the amount of spreading:

[0072] Two-component binder 1.4kg / m 2 ;

[0073] Rubber modified asphalt 1.6kg / m 2 ;

[0074] Single particle size crushed stone 70% coverage.

[0075] The two-component adhesive is a two-component epoxy resin adhesive, and the curing strength reaches more than 60% of the final strength within 30 minutes, and the final strength exceeds 10Mpa.

[0076] The two-component epoxy resin binder adopts bisphenol F type epoxy resin, which is Taiwan Nanya NPEF-170 bisphenol F type epoxy resin.

[0077] The rubber-modified asphalt is 40% waste tire rubber powder-modified asphalt with a softening point of not less than 75°C. It is purchased from Jiangsu Baoli Asphalt Company...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com