Method for transition from non-pillar sublevel caving method to upward horizontal cut-and-fill method

A segmented caving method and no bottom pillar technology, which is applied in the direction of filling, earth drilling, safety devices, etc., can solve the problems of complex mining process, increased ore loss rate, and reduced resource utilization rate of the filling method, achieving The effect of reducing the dilution rate, increasing the recovery rate, reducing the loss rate and the dilution rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

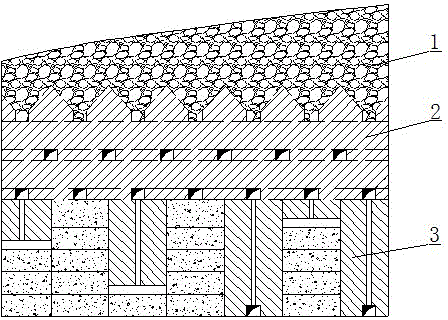

[0021] It is a method of transitioning upward from the sub-level caving method without pillars to the horizontal layered filling method. The method as figure 1 As shown, in a stage immediately below the caving area 1 of the mining area, the stage is divided into an isolation zone 2 and a mining zone 3, the upper part of the stage is the isolation zone 2, and the lower part of the stage is the mining zone 3.

[0022] The mining sequence of the stages is that the mining area is mined first, and then the isolation zone 2 is mined.

[0023] The mining method in the said stage is that the mining area 3 adopts the upward horizontal layered filling method, and the isolation zone 2 adopts the segmental caving method without bottom pillars.

[0024] The thickness of the isolation zone 2 is 1 time of the subsection height of the non-bottom column subsection caving method.

[0025] The post-mining isolation zone 2 refers to mining the isolation zone 2 after the filling body in the mini...

Embodiment 2

[0027] It is a method of transitioning upward from the sub-level caving method without pillars to the horizontal layered filling method. The method as figure 1 As shown, in a stage immediately below the caving area 1 of the mining area, the stage is divided into an isolation zone 2 and a mining zone 3, the upper part of the stage is the isolation zone 2, and the lower part of the stage is the mining zone 3.

[0028] The mining sequence of the stages is that the mining area is mined first, and then the isolation zone 2 is mined.

[0029] The mining method in the said stage is that the mining area 3 adopts the upward horizontal layered filling method, and the isolation zone 2 adopts the segmental caving method without bottom pillars.

[0030] The thickness of the isolation zone 2 is twice the subsection height of the non-bottom column subsection caving method.

[0031] The post-mining isolation zone 2 refers to mining the isolation zone 2 after the filling body in the mining a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com