Equal-channel shear extrusion mold and molding method

An extrusion die and equal channel technology, applied in the field of channel shear extrusion die and forming, can solve the problems of high cost, difficult processing, large load, etc., and achieve high plastic deformation, low load requirements, and low production costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention is further illustrated by the following examples, but not limited to the following examples.

[0036] A cuboid pure aluminum billet with dimensions of 100 mm×100 mm×300 mm was subjected to equal channel shear extrusion.

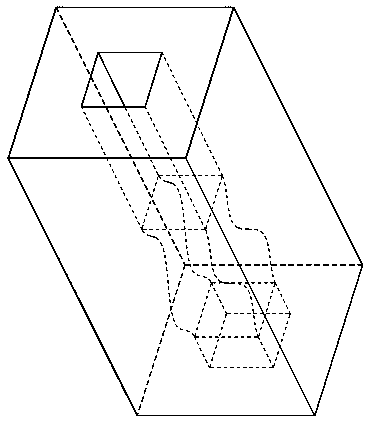

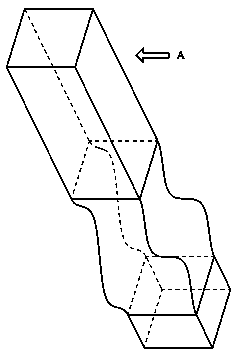

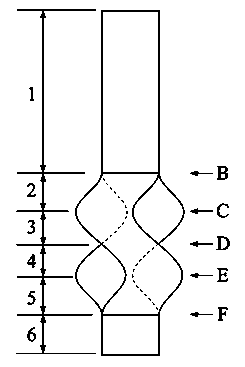

[0037] Figure 1~4 It shows the structure of the equal-channel shear extrusion die. The outside is a cuboid structure, and the inside is a cavity. Two of the four sides of the cavity wall are parallel planes, and the other two are curved surfaces. , the cavity is divided into entry section 1, shear deformation section 2, shear deformation-recovery section 3, shear deformation section 2 4, shear deformation 2 recovery section 5, and exit section 6; where:

[0038] The cavity of the inlet section 1 is a cuboid structure, and its cross section is a square section. The shape and size of the square section are the same as those of the blank cross section. The side length of the square section is 100 mm, and the height of the inlet sec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com