Variable sieve pore and reciprocating pressure vibration combined pulp screening equipment

A compound and sieve technology, which is applied in textiles, papermaking, and fiber raw material processing, can solve the problems of low screening efficiency and low output of good pulp, and achieve the effect of increasing the screening area, facilitating feeding, and realizing automatic sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

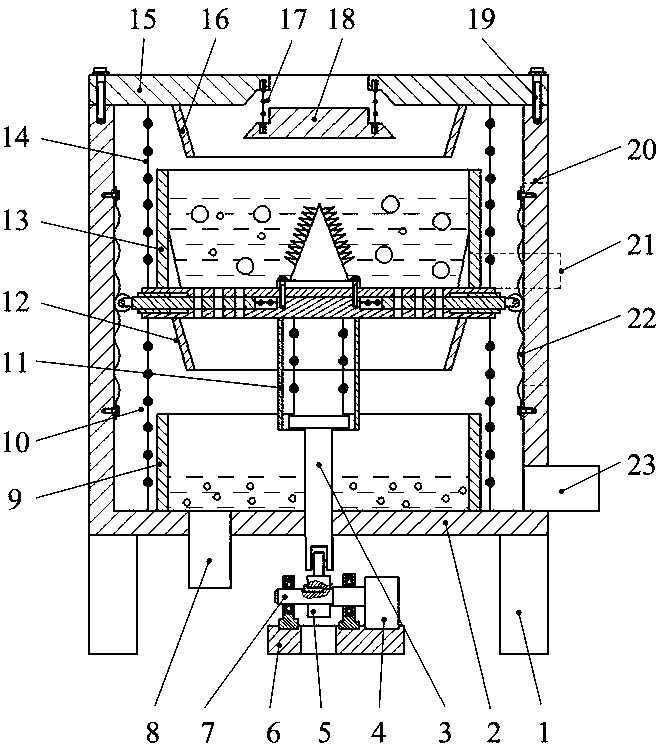

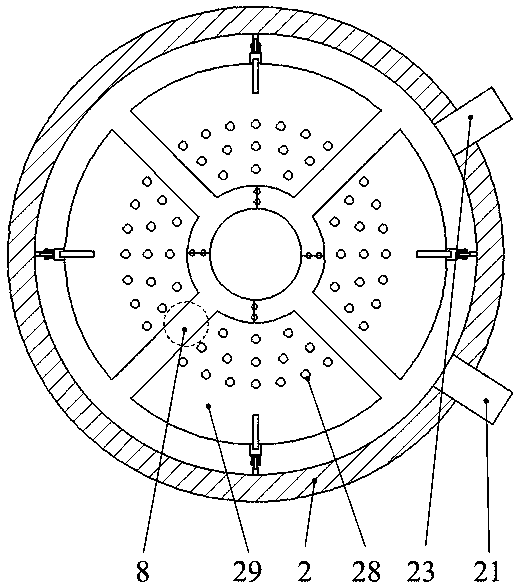

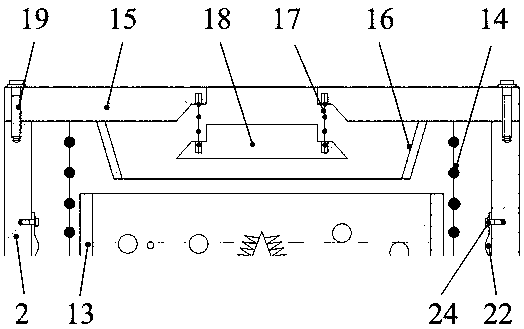

[0050] Such as figure 1 , figure 2 , image 3 and Figure 4 As shown, a kind of variable sieve hole and reciprocating pressure vibration composite pulp screening equipment of the present invention mainly includes a good pulp generating device, a power drive device, a reciprocating pressure vibration device, a 28-diameter reducing device for screen holes, a slurry storage device, Guide flow device and turbulence crushing device, power drive device is installed at the lower end of the fine pulp generating device, reciprocating pressure vibration device and sieve hole 28 variable diameter device are respectively installed in the middle of the good pulp generating device, slurry storage device is installed at the reciprocating pressure The upper and lower sides of the vibrating device, the guiding and diverting device is installed above the slurry storage device, and the turbulent breaking device is installed above the reciprocating vibration device.

[0051] The present inven...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com