Method for rapidly refining metastable austenite grain structure

A technology for austenite grain refinement, which is applied in the field of rapid refinement of metastable austenite grain structure, can solve the problem of low grain refinement strengthening efficiency, and achieve the purpose of suppressing dynamic recovery or recrystallization, grain small tissue effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

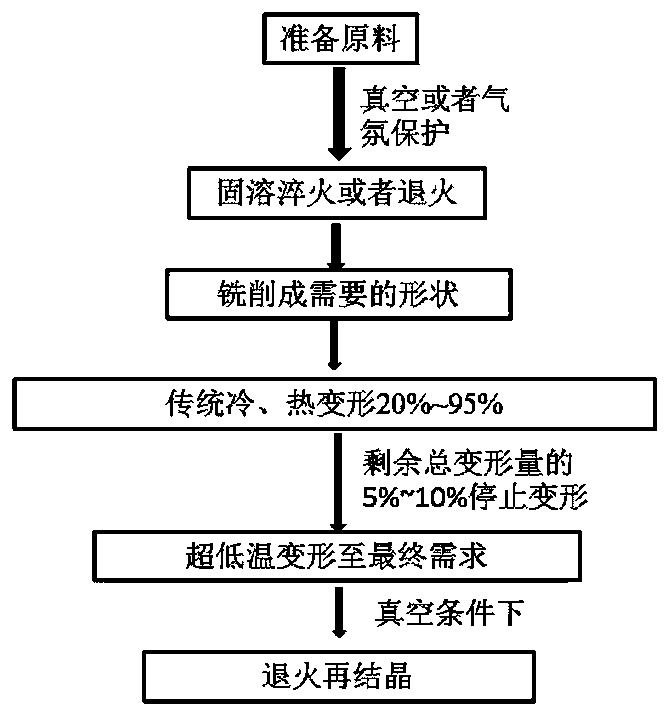

Method used

Image

Examples

Embodiment 1

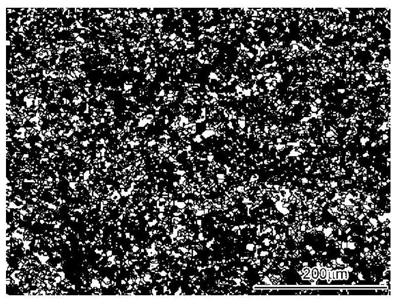

[0036] Mill the commercial 304 stainless steel hot-rolled plate to the upper and lower surfaces smooth and the required size. The material obtained after milling is vacuum-sealed and kept in an air furnace at 1100°C for 1 hour. After being released from the furnace, it is quickly water quenched. The stainless steel plate is cold-rolled and deformed, and the deformation of each pass is 10%. After one pass of cold rolling, it goes directly to the next pass of rolling, that is, continuous cold rolling, to obtain a rolled sheet material with a deformation of 70%, and then put the cold-rolled sheet into Soak in liquid nitrogen for 5 minutes, and then carry out ultra-low temperature rolling after soaking. Finally, the total deformation of the plate is 80%. Finally, the plate is heat-treated and annealed at 850°C for 5 minutes. The total processing time is 20 minutes, figure 2 This is the final photo of the grain structure, the grain size is 4.5 μm.

Embodiment 2

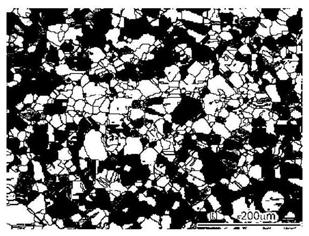

[0038] Milling of commercial 304 stainless steel hot rolled plate to the upper and lower surface finish and required size. After the plate is vacuum sealed, it is kept in an air furnace at 1100°C for 1 hour. After being out of the furnace, it is quickly water-quenched, and then the quenched 304 stainless steel plate is cold-rolled and deformed at room temperature. The deformation of each pass is 10%. Then go directly to the next rolling, that is, continuous cold rolling, to obtain a rolled plate with a deformation of 30%, and then put the cold-rolled plate into liquid nitrogen for 10 minutes, and then perform ultra-low temperature rolling on the soaked rolling, The final total deformation was 50% of the sheet. Finally, heat treatment and annealing are performed on the plate, the annealing temperature is 850°C, and the temperature is kept for 5 minutes. The total processing time is 25 minutes, image 3 The photo of the final grain structure, the grain size is 8.7 μm.

Embodiment 3

[0040]Milling of commercial 304 stainless steel hot rolled plate to the upper and lower surface finish and required size. After the plate is vacuum sealed, it is kept in an air furnace at 1100°C for 1 hour. After being out of the furnace, it is quickly water-quenched, and then the quenched 304 stainless steel plate is cold-rolled and deformed at room temperature. The deformation of each pass is 10%. Then go directly to the next rolling, that is, continuous cold rolling, to obtain a rolled plate with a deformation of 20%, and then put the cold-rolled plate into liquid nitrogen for 10 minutes, and then perform ultra-low temperature rolling on the soaked rolling, Finally, the total deformation of the plate is 30%. Finally, the plate is annealed by heat treatment. The annealing temperature is 850°C, the temperature is kept for 5 minutes, and the total processing time is 25 minutes. Figure 4 This is the final grain structure photo, with a grain size of 10 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Grain size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com