Low-grade magnesite selective dissociation equipment and method

A magnesite, low-grade technology, applied in grain processing and other directions, can solve the problems of high magnesite recovery rate, low recovery rate, poor selectivity, etc., and achieve the effect of improving comprehensive utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

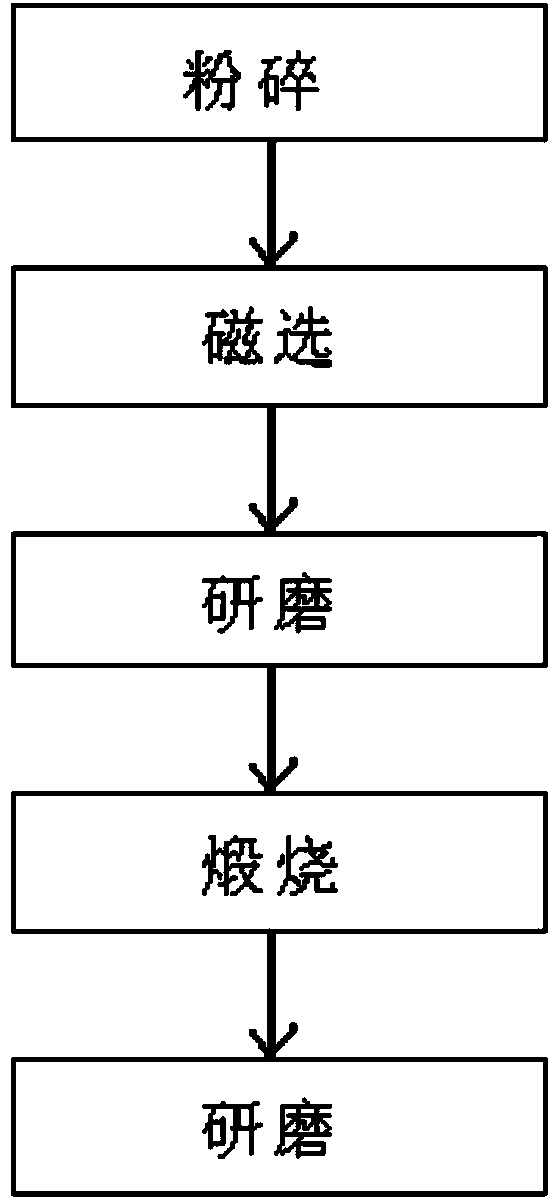

[0024] This embodiment selects the low-grade magnesite in the Dashiqiao area. In the low-grade magnesite, the mass content of MgO is 40%, the mass content of calcium oxide is 2.3%, the mass content of silicon dioxide is 4%, and the mass content of iron oxide is 4%. The content is 0.8%. The low-grade magnesite selective dissociation method is as follows figure 1 shown, including the following steps:

[0025] (1) Put the low-grade magnesite in the pulverizing equipment, and pulverize it to a particle size of 3-5 mm. The pulverizing equipment used includes a roller crusher and a vibrating screen group.

[0026] (2), the low-grade magnesite obtained by pulverizing in the step (1) is placed in a magnetic separator for magnetic separation, and the magnetic field intensity used in the magnetic separation is 3.2T; after the magnetic separation, the magnesite in the magnesite (ore concentrate) The content of silicon dioxide is reduced to less than 1.5%, the content of iron oxide is r...

Embodiment 2

[0031] The mass content of MgO in the low-grade magnesite treated in this embodiment is 41%, the mass content of calcium oxide is 3%, the mass content of silicon dioxide is 3.2%, and the mass content of iron oxide is 0.7%. The low-grade magnesite selective dissociation method comprises the following steps:

[0032] (1) Put the low-grade magnesite in the crushing equipment, and crush it until the particle size is 5-8mm.

[0033] (2), the low-grade magnesite obtained by pulverizing in step (1) is placed in a magnetic separator for magnetic separation, and the magnetic field intensity used in the magnetic separation is 5T; after magnetic separation, the magnesite (ore concentrate) The content of silicon dioxide is reduced to below 1.8%, the content of iron oxide is reduced to below 0.3%, and the content of calcium oxide is reduced to below 1.6%.

[0034] (3), the magnesite obtained in step (2) is placed in a grinding device for grinding, so that the magnesite, calcite, quartz, a...

Embodiment 3

[0038] The mass content of MgO in the low-grade magnesite treated in this embodiment is 41%, the mass content of calcium oxide is 2.0%, the mass content of silicon dioxide is 5%, and the mass content of iron oxide is 0.5%. The low-grade magnesite selective dissociation method comprises the following steps:

[0039] (1) Put the low-grade magnesite in the crushing equipment, and crush it until the particle size is 5-8mm.

[0040] (2), the low-grade magnesite obtained by pulverizing in step (1) is placed in a magnetic separator for magnetic separation, and the magnetic field intensity used in the magnetic separation is 2.5T; after magnetic separation, the magnesite (ore concentrate) The content of silicon dioxide in magnesite is reduced to less than 2.0%, the content of iron oxide is reduced to less than 0.2%, and the content of calcium oxide is reduced to less than 1.3%. Magnetic separation greatly reduces the content of iron oxide in magnesite. The content of iron oxide direct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com