Method for strengthening vibration fatigue performance of metal material by laser peening and ultralow temperature coupling

A technology of metal material and laser peening, which is applied in the field of metal material processing, can solve the problems such as the selection of process parameters, and achieve the effects of improving anti-vibration fatigue performance, improving stability, improving metal damping capacity and fracture strength and toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

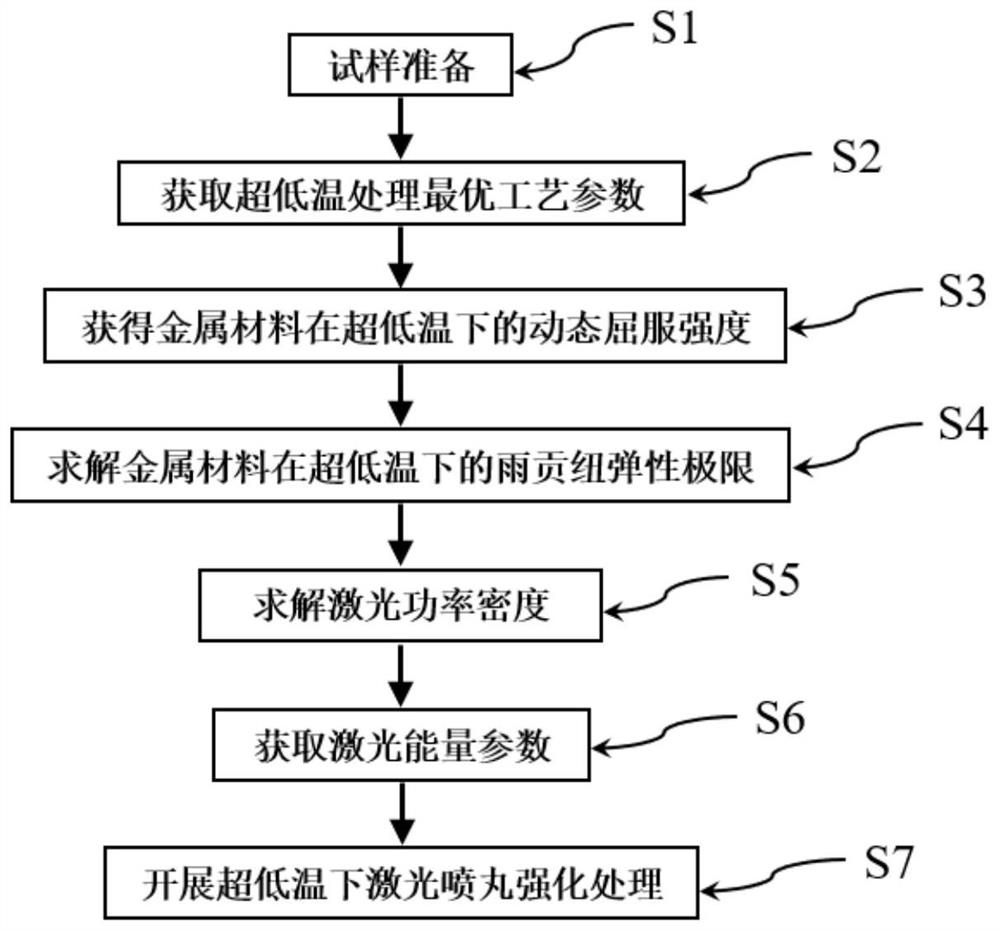

[0025] A method of coupling laser peening and ultra-low temperature to strengthen the vibration fatigue performance of metal materials, see figure 1 , including the following steps:

[0026] (1) Sample preparation:

[0027] Grind and polish the surface of the TC4 titanium alloy, then use an ultrasonic cleaner to clean the sample in an industrial alcohol solution for 20 minutes, and finally take it out and dry it with a hair dryer;

[0028] (2) Obtain the optimal process parameters for ultra-low temperature treatment:

[0029] Using liquid nitrogen as the refrigerant, the TC4 titanium alloy is subjected to ultra-low temperature treatment under the parameters of ultra-low temperature of -50--196 °C, ultra-low temperature treatment retention time of 0.5-10 h, and cooling rate of 10-50 °C / min; The maximum residual compressive stress value and microhardness on the surface of the titanium alloy sample are the optimization goals, and the optimal ultra-low temperature treatment proc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com