Alkylated waste acid cracking technology adopting sulphur as fuel

A technology for alkylating waste acid and sulfur, which is applied in the chemical industry, sulfur compounds, sulfur dioxide/sulfurous acid, etc., and can solve the problems of increasing the load of the acid making system and waste discharge, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

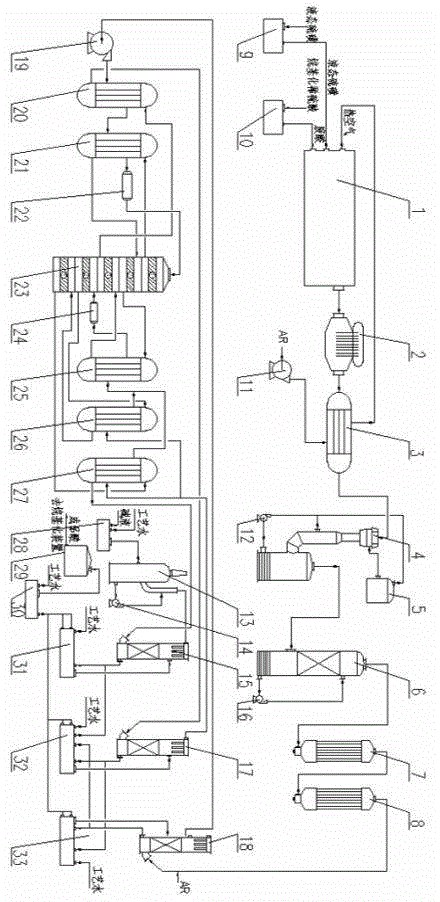

[0011] Example: such as figure 1 As shown, the present embodiment uses sulfur as the fuel alkylation waste acid cracking process including:

[0012] The liquid sulfur in the liquid sulfur underground tank (9) is injected into the cracking furnace (1) together with the air (~220°C) preheated by the air preheater (3) for combustion, and the temperature in the furnace is controlled at about 1000-1100°C . The waste sulfuric acid from the waste acid underground tank (10) is sprayed into the waste acid cracking furnace (1) for pyrolysis. 1000-1100°C SO from cracking furnace (1) 2 Furnace gas, after heat removal through the waste heat boiler (2), the temperature drops to about 450°C, and then enters the air preheater (3), after the temperature of the furnace gas is reduced from 450°C to about 300°C, the furnace gas enters the purification section Power Wave Scrubber (4). At the same time, the air that reacts with the liquid sulfur in the furnace is preheated by the air preheater ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com