Method for reducing ardealite decomposition temperature

A decomposition temperature, phosphogypsum technology, applied in the direction of sulfur dioxide/sulfurous acid, calcium/strontium/barium oxide/hydroxide, etc., can solve the problems of high decomposition temperature, unreasonable economy, difficult to popularize and apply, etc. The effect of reduction, production cost reduction and process simplification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

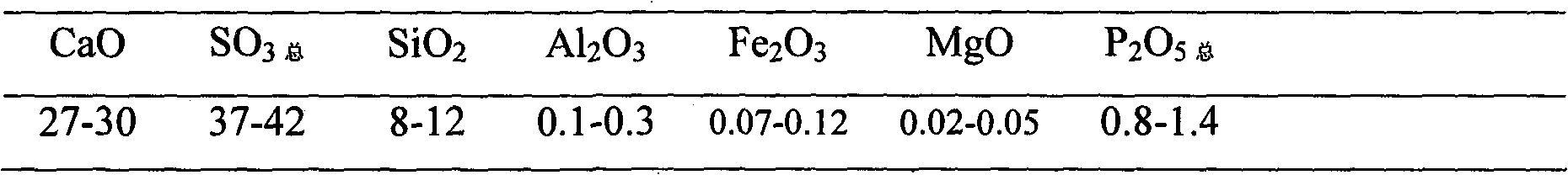

Method used

Image

Examples

Embodiment 1

[0041] Example 1: Dry phosphogypsum at 100-110°C for 5 hours, remove free water, grind and pass through a 120-mesh standard sampling sieve, take 100g of dry phosphogypsum and dry coal and additives by 100 parts phosphorus Gypsum + 5 parts of coal + 3 parts of admixture (ingredient 2) are mixed evenly and placed in a quartz tube and placed in a tubular resistance furnace. The heating rate of the tubular resistance furnace is controlled at 20°C / min, and the reaction is performed at a temperature of 700°C-850°C 3 hours until outlet flue gas SO 2 When the content reaches 14%, the heating is stopped, and the composition of the solid slag is measured after natural cooling. It is calculated that the decomposition rate of phosphogypsum is 97%, and the desulfurization rate is 91.5%.

Embodiment 2

[0042] Example 2: Dry phosphogypsum at 100-110°C for 5 hours, remove free water, grind it through a 120-mesh standard sampling sieve, take 100g of dry phosphogypsum and dry coal and additives by 100 parts phosphorus Gypsum + 5 parts of coal + 3.5 parts of admixture (ingredient 3) are mixed evenly and placed in a quartz tube and placed in a tubular resistance furnace. The heating rate of the tubular resistance furnace is controlled at 20°C / min, and the reaction is performed at a temperature of 700°C-750°C 3.5 hours until outlet flue gas SO 2 When the content reaches 14%, the heating is stopped, and the composition of the solid slag is measured after natural cooling. The calculated decomposition rate of phosphogypsum is 96.5%, and the desulfurization rate is 92%.

Embodiment 3

[0043] Example 3: Dry phosphogypsum at 100-110°C for 5 hours, remove free water, grind and pass through a 120-mesh standard sampling sieve, take 100g of dry phosphogypsum and dry coal and additives by 100 parts phosphorus Gypsum + 6 parts of coal + 3 parts of admixture (ingredient 4) are mixed evenly and placed in a quartz tube and placed in a tubular resistance furnace. The heating rate of the tubular resistance furnace is controlled at 20°C / min. At the same time, add reducing gas (ingredient 5) at a flow rate of 5ml / min and react for 3 hours until the outlet flue gas SO 2 When the content reaches 14%, the heating is stopped, and the composition of the solid slag is measured after natural cooling. The calculated decomposition rate of phosphogypsum is 98%, and the desulfurization rate is 93.5%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| decomposition efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com