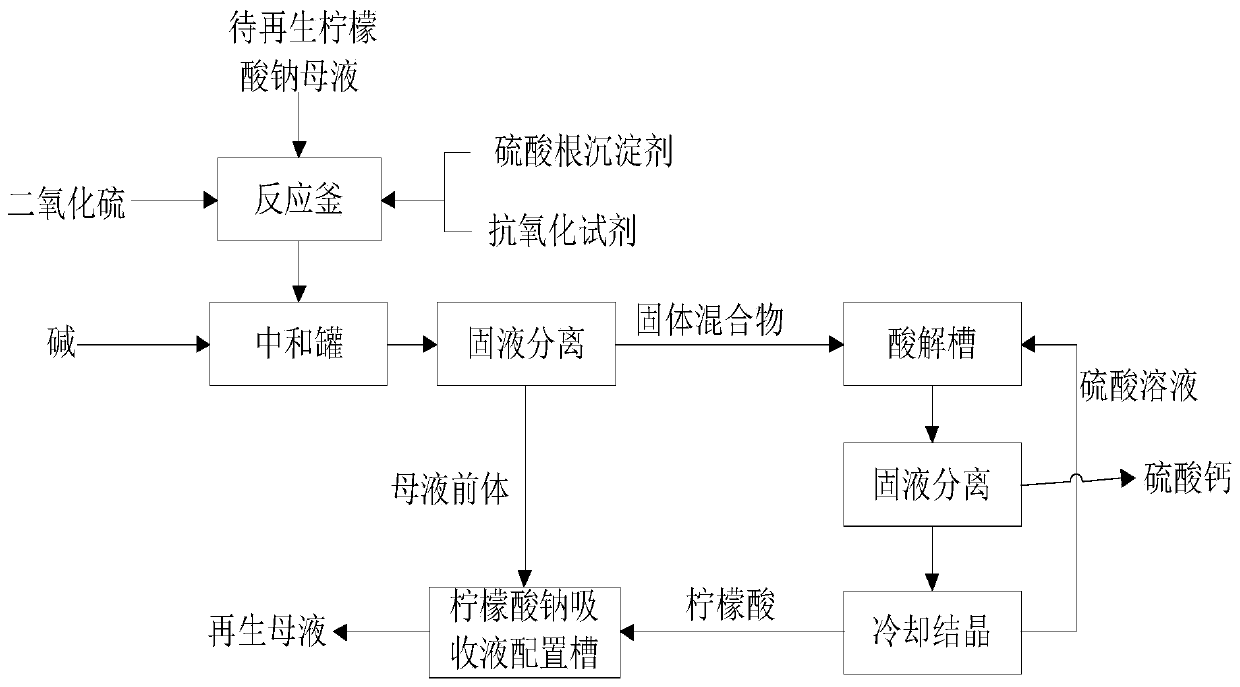

A kind of mother liquor regeneration method of sodium citrate method for liquid sulfur dioxide

A liquid sulfur dioxide, sodium citrate technology, applied in the direction of sulfur dioxide/sulfurous acid, calcium/strontium/barium sulfate, etc., can solve the problem of difficult removal of sulfate, and achieve the effect of effective recycling and resource saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Detect the content of citrate and vitriol in the sodium citrate circulation mother liquor to be regenerated, the citric acid content is 205g / L (all citrate ions are also converted into citric acid, hereinafter the same) in the sodium citrate circulation mother liquor, sulfate ( Sodium sulfate) content 116g / L, add the calcium hydroxide aqueous solution of concentration 10wt% according to sulfate radical and lemon root total molar ratio 1:0.9 in citric acid mother liquor (citrate radical and sulfate radical total molar number is the ratio of calcium hydroxide molar number 1:0.9), add 0.1% of the total mass of sodium citrate mother liquor antioxidant reagent catechol, stir and mix evenly; feed 100vol% sulfur dioxide gas (i.e. pure sulfur dioxide) into the mixed slurry solution to When the pH of the solution is less than 3.5, stop feeding sulfur dioxide, react for another 30-60 minutes, and then neutralize with 30wt% caustic soda solution to pH 5; filter and separate to obta...

Embodiment 2

[0036] Get 1000L citric acid circulation mother liquor and add in the reactor, the citric acid 210g / L in the sodium citrate circulation mother liquor, sulfate content 126g / L, add the calcium hydroxide of 1800kg concentration 10wt% in the reactor, 0.13kg antioxidant reagent o-Phenylenediamine, stir and mix evenly; feed pure sulfur dioxide gas until the pH of the solution is less than 3.5 (time-consuming about 45min), stop feeding sulfur dioxide, and then react for 30-60min; And to pH is 7; Filtration separation obtains solid mixture 675.5kg (wherein calcium sulfate 173.5kg, calcium citrate 502kg) and mother liquor precursor, the sulfuric acid acid hydrolysis calcium citrate of solid mixture with concentration 60wt% obtains citric acid solution, concentrates , cooling, crystallization and filtration to obtain citric acid crystals, and the sulfuric acid filtrate can be reused to acidify the solid mixture of calcium citrate and calcium sulfate; the sulfate content in the mother liq...

Embodiment 3

[0038] Get 1000L citric acid circulation mother liquor and add in the reactor, the citric acid content in the sodium citrate circulation mother liquor is 210g / L, and the sulfate content is 126g / L. Add 1800kg of calcium hydroxide with a concentration of 20% in the reactor, 0.12kg of antioxidant reagent hydrazine hydrate, stir and mix evenly; feed 8vol% sulfur dioxide gas and until the pH of the solution is less than 3.5 (time-consuming 240min), stop feeding sulfur dioxide, and then React for 45 minutes; Use 30wt% caustic soda to neutralize the pH of the reaction system to 5-6; Filter and separate to obtain solid mixture 673.2kg (wherein calcium sulfate 170.3kg, calcium citrate 502.9kg) and mother liquor precursor, solid mixture with concentration 70wt % sulfuric acid acid hydrolysis of calcium citrate to obtain citric acid solution, concentration, cooling, crystallization and filtration to obtain citric acid crystals, the sulfuric acid filtrate can be reused for acid hydrolysis ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com