A kind of functionalized porous graphene and preparation method thereof

A porous graphene, functionalized technology, applied in graphene, chemical instruments and methods, carbon compounds, etc., can solve the problem of reducing ion transmission efficiency and effective specific surface area of electrodes, poor performance of graphene-based supercapacitors, and material surface generation. Large cracks and other problems, to achieve large-scale production, reduce the reduction of the effective specific surface area of the electrode, and reduce the reduction of ion transmission efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

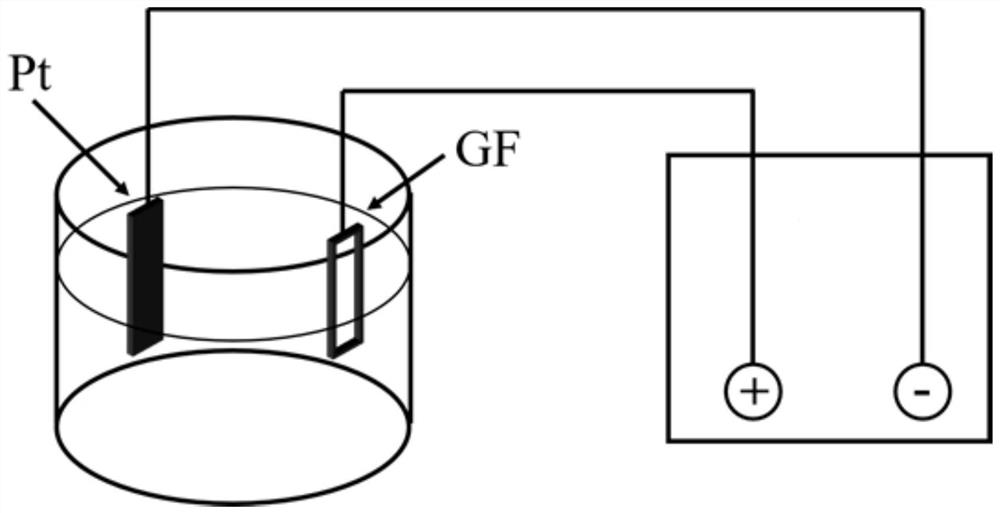

[0029] Such as figure 1 As shown, the invention provides a kind of preparation method of functionalized porous graphene, it is characterized in that, the method comprises the steps:

[0030] (a) The mixed solution of phytic acid and ammonium sulfate is used as the electrolyte, the graphite foil with a size of 1cm×2cm~1cm×4cm is used as the anode, and the platinum sheet is used as the cathode, and assembled to form a two-electrode electrolysis system, the phytic acid in the electrolyte The concentration is preferably 0.02mol / L-0.04mol / L, and the concentration of ammonium sulfate is 0.08mol / L-0.12mol / L;

[0031] (b) In the two-motor electrolysis system of step (a), a DC power supply is used to provide a DC bias voltage of +8V to +12V for the anode, and the graphite foil gradually expands and peels off to form graphene under the action of the bias voltage, and is released to the In the electrolyte;

[0032] (c) the graphene-containing electrolytic solution obtained in step (b) ...

Embodiment 1

[0035] (a) A mixed solution with a phytic acid concentration of 0.03mol / L and an ammonium sulfate concentration of 0.1mol / L is used as the electrolyte, a graphite foil with a size of 1cm×3cm is used as the anode, and a platinum sheet is used as the cathode to form a two-electrode electrolysis system ;

[0036] (b) A DC power supply is used to provide a DC bias voltage of +10V for the anode, and the graphite foil gradually expands and peels off to form graphene under the action of the bias voltage, and releases it into the electrolyte;

[0037] (c) The graphene-containing electrolyte solution obtained in step (b) is ultrasonically dispersed for 30 min to disperse the graphite foil therein, then repeatedly filtered and cleaned with a mixed cellulose membrane to remove residual impurities, and the obtained filtrate is spun at a speed of 4500r Centrifuge under the condition of / min for 20min, select the supernatant to obtain a suspension of functionalized porous graphene, and fina...

Embodiment 2

[0042] (a) A mixed solution with a phytic acid concentration of 0.02mol / L and an ammonium sulfate concentration of 0.12mol / L is used as the electrolyte, a graphite foil with a size of 1cm×2cm is used as the anode, and a platinum sheet is used as the cathode to form a two-electrode electrolysis system ;

[0043] (b) A DC power supply is used to provide a DC bias voltage of +8V for the anode, and the graphite foil gradually expands and peels off to form graphene under the action of the bias voltage, and releases it into the electrolyte;

[0044] (c) The graphene-containing electrolytic solution obtained in step (b) is ultrasonically dispersed for 20 min to disperse the graphite foil therein, then repeatedly filtered and cleaned with a mixed cellulose membrane to remove residual impurities, and the obtained filtrate is heated at a speed of 6000r Centrifuge under the condition of / min for 15min, select the supernatant to obtain a suspension of functionalized porous graphene, and f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com