Heavy metal removal process used in zinc borate preparation process

A preparation process, a technology of zinc borate, applied in the field of halogen-free flame retardants, can solve the problems of excessive heavy metals in the final product, reducing the accumulation of heavy metals, changing the distribution ratio of heavy metals, etc., achieving controllable conditions, simple process operation, and strong operability effect of reproducibility and reproducibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

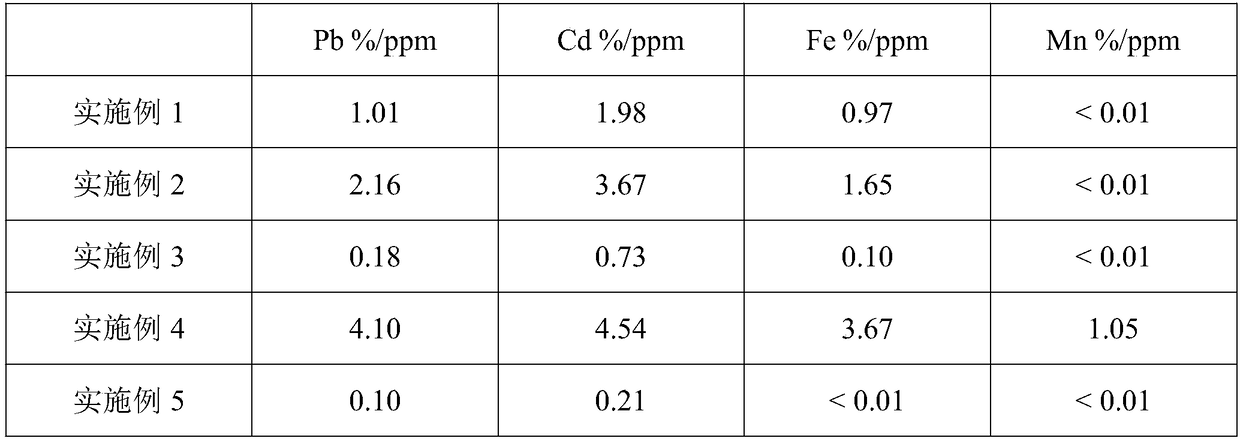

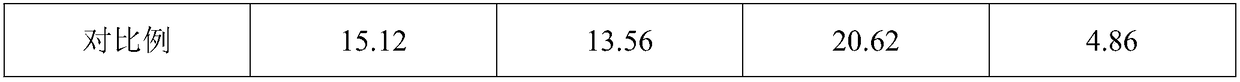

Examples

Embodiment 1

[0021] (1) Add 460g (1mol) of zinc sulfate solution to the reaction bottle, start stirring, keep the system temperature at 25°C, add 2.3g of 80 mesh zinc powder, stir for 15min, separate to obtain purified zinc sulfate solution, add 250g (2mol) Add dropwise this zinc sulfate solution in 32% liquid caustic soda, 25 ℃ of stirring reaction 40min, filter to obtain zinc hydroxide filter cake, dry to obtain zinc hydroxide 99.1g; (2) to 719.19g (3.49mol) boric acid 14g of 98% concentrated sulfuric acid was added dropwise to the solution, then 99.1g (0.997mol) of zinc hydroxide prepared was added to the mixed solution, stirred and heated to 95°C for 6 hours, and the zinc borate product with low heavy metal content was separated and obtained. Mother liquor; (3) Add 2.5 g of 80-mesh zinc powder to the obtained boric acid mother liquor, stir at 45° C. for 10 minutes, filter and separate to remove heavy metals, and the boric acid mother liquor can be used mechanically.

Embodiment 2

[0023] (1) Add 460g (1mol) of zinc sulfate solution to the reaction bottle, start stirring, keep the system temperature at 25°C, add 0.4g of 80 mesh zinc powder, stir for 15min, separate to obtain purified zinc sulfate solution, add 250g (2mol) Add dropwise this zinc sulfate solution in 32% liquid caustic soda, 25 ℃ of stirring reaction 40min, filter to obtain zinc hydroxide filter cake, dry to obtain zinc hydroxide 99.1g; (2) to 719.19g (3.49mol) boric acid 11g of 98% concentrated sulfuric acid was added dropwise in the solution, then 99.1g (0.997mol) of the prepared zinc hydroxide was added to the mixed solution, the temperature was stirred to 95°C for 6h, and the zinc borate product with low heavy metal content was separated and obtained. Mother liquor; (3) Add 0.5 g of 80-mesh zinc powder to the obtained boric acid mother liquor, stir at 45° C. for 10 minutes, filter and separate to remove heavy metals, and the boric acid mother liquor can be used mechanically.

Embodiment 3

[0025] (1) Add 460g (1mol) of zinc sulfate solution to the reaction bottle, start stirring, keep the system temperature at 25°C, add 4.6g of 80-mesh zinc powder, stir for 15min, separate to obtain purified zinc sulfate solution, and add 250g (2mol) Add dropwise this zinc sulfate solution in 32% liquid caustic soda, 25 ℃ of stirring reaction 40min, filter to obtain zinc hydroxide filter cake, dry to obtain zinc hydroxide 99.1g; (2) to 719.19g (3.49mol) boric acid 17g of 98% concentrated sulfuric acid was added dropwise into the solution, then 99.1g (0.997mol) of zinc hydroxide prepared was added to the mixed solution, stirred and heated to 95°C for 6 hours, and the zinc borate product with low heavy metal content was separated and obtained. Mother liquor; (3) Add 5.0 g of 80-mesh zinc powder to the obtained boric acid mother liquor, stir at 45° C. for 10 minutes, filter and separate to remove heavy metals, and the boric acid mother liquor can be used mechanically.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com