Amorphous plating layer with high hydrogen evolution catalytic activity and preparation method thereof

A catalytic activity and coating technology, applied in the field of electrocatalytic hydrogen evolution, can solve the problems of high price, difficult to large-scale industrial production, complex process, etc., and achieve the effects of short preparation process, improved power utilization efficiency, and simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

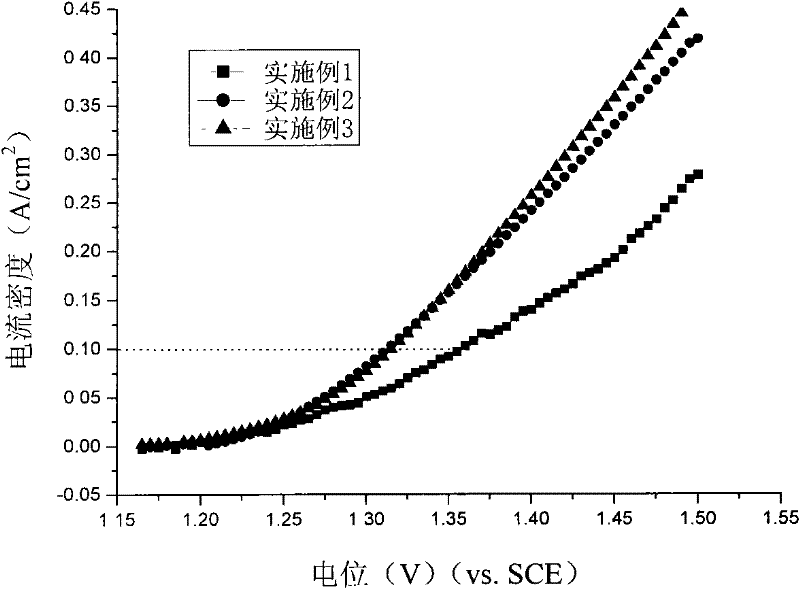

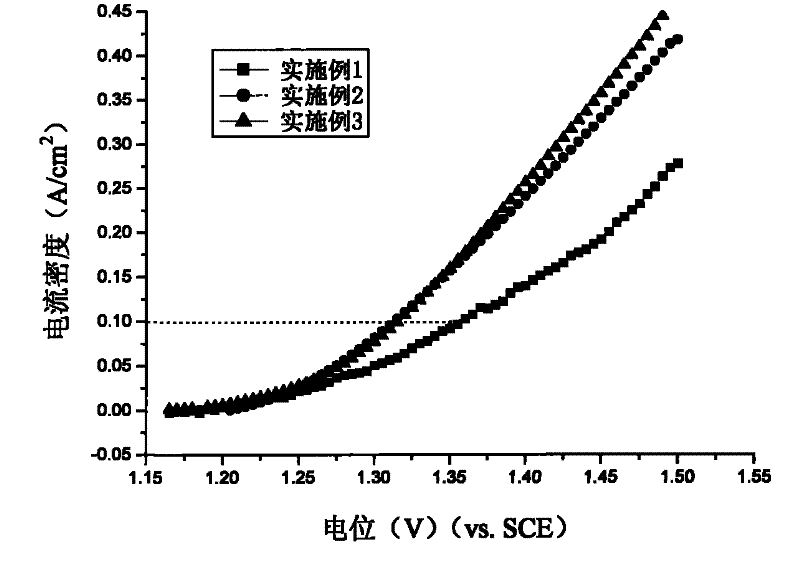

Embodiment 1

[0021] Take the copper sheet and cut it into a sample of 15mm×15mm×4mm, and weld the copper wire on it, and seal the non-working surface with epoxy resin. The working surface is polished with 360#---1000# water sandpaper in sequence, and then polished with a polishing machine, and then pre-treatment processes such as alkali cleaning, acetone degreasing, hot water washing, strong etching and weak etching are used. Deionized water cleaning, put into the plating solution. The anode selected is a nickel plate, and the area ratio of yin and yang is 1:3. The process conditions of electrodeposition are as follows: plating solution pH=8, temperature T=25°C, electrodeposition time t=60min, current density Dk=10mA / cm 2 . The composition of the electroplating solution is: NiSO 4 ·6H 2 O 40g / L, CoSO 4 ·7H 2 O 2g / L, Na 2 MoO 4 2H 2 O 15g / L, Na 3 C 6 h 5 o 7 2H 2 O 10g / L and Na 2 CO 3 60g / L. The prepared amorphous coating was tested, and the weight percentages of Ni, Mo and...

Embodiment 2

[0023] Take the copper sheet and cut it into a sample of 15mm×15mm×4mm, and weld the copper wire on it, and seal the non-working surface with epoxy resin. The working surface is polished with 360#---1000# water sandpaper in sequence, and then polished with a polishing machine, and then pre-treatment processes such as alkali cleaning, acetone degreasing, hot water washing, strong etching and weak etching are used. Deionized water cleaning, put into the plating solution. The anode selected is a nickel plate, and the area ratio of yin and yang is 1:3. The process conditions of electrodeposition are as follows: plating solution pH=9, temperature T=30°C, electrodeposition time t=60min, current density D k =20mA / cm 2 . The composition of the electroplating solution is: NiSO 4 ·6H 2 O 60g / L, CoSO 4 ·7H 2 O 5g / L, Na 2 MoO 4 2H 2 O20g / L, Na 3 C 6 h 5 o 7 2H 2 O 10g / L and Na 2 CO 3 80g / L. The prepared amorphous coating was tested, and the weight percentages of Ni, Mo a...

Embodiment 3

[0025]Take the copper sheet and cut it into a sample of 15mm×15mm×4mm, and weld the copper wire on it, and seal the non-working surface with epoxy resin. The working surface is polished with 360#---1000# water sandpaper in sequence, then polished with a polishing machine, and then pre-treated by alkali cleaning, acetone degreasing, hot water washing, strong etching and weak etching, etc. Deionized water cleaning, put into the plating solution. The anode selected is a nickel plate, and the area ratio of yin and yang is 1:3. The process conditions of electrodeposition are as follows: plating solution pH=10, temperature T=35°C, electrodeposition time t=60min, current density D k =20mA / cm 2 . The composition of the electroplating solution is: NiSO 4 ·6H 2 O 80g / L, CoSO 4 ·7H 2 O 8g / L, Na 2 MoO 4 2H 2 O 30g / L, Na 3 C 6 h 5 o 7 2H 2 O 15g / L and Na 2 CO 3 100g / L.

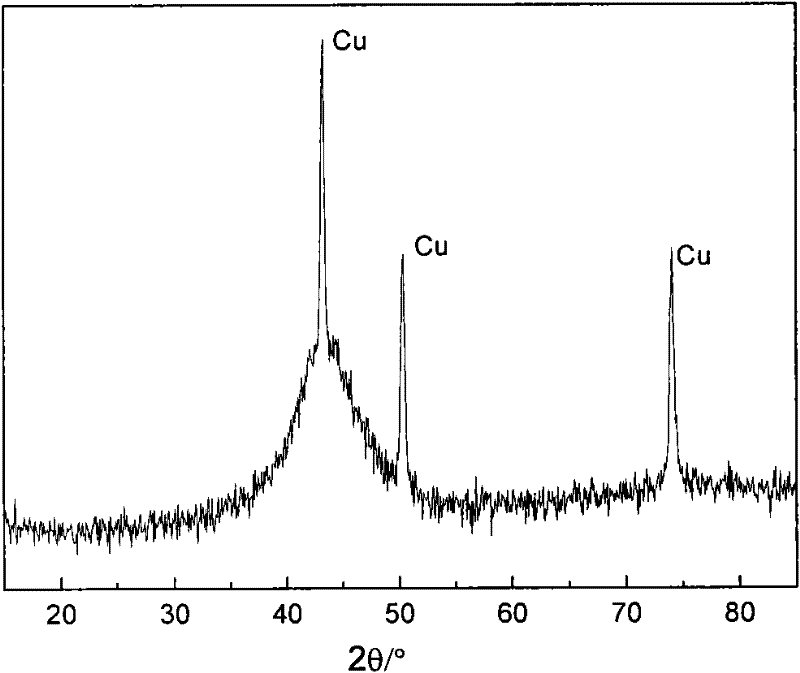

[0026] figure 2 For the small angle grazing figure of the Ni-Mo-Co amorphous coating prepared in emb...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com