Annular nugget resistance spot welding numerical simulation method

A resistance spot welding and numerical simulation technology, applied in 3D modeling, image data processing, special data processing applications, etc., can solve the problems of contact surface microscopic model and unreasonable contact resistance, avoid a large number of repeated experiments, reduce Errors, effects of reliable technical means

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The detailed content of the present invention and its specific implementation will be further described below in conjunction with the accompanying drawings.

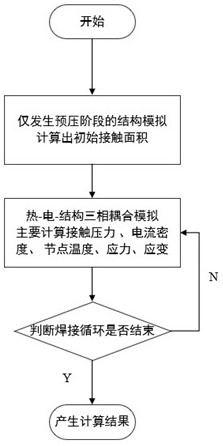

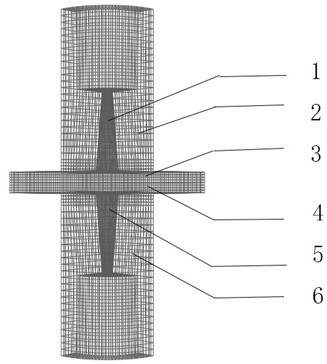

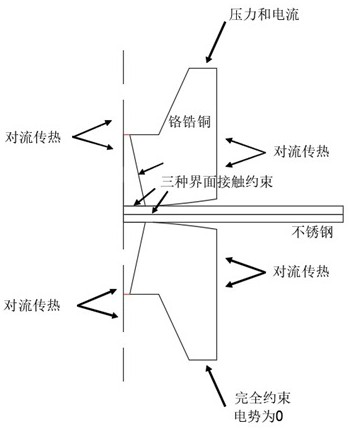

[0041] The implementation process includes establishing geometric models, assigning material properties, component assembly, setting analysis steps, setting contact properties, specifying boundary conditions and loads, dividing meshes, submitting job solutions and post-processing steps. Figure 1 It is the operation logic of the above numerical simulation. In the pre-pressurization and pressurization stages, the CAE model only performs structural simulation to calculate the initial contact area. Then, in the electrification stage, the initial contact area is the first conduction position between the electrode part and the workpiece part, and becomes the heat source. - The initial environment of electrical-structural three-phase coupling calculation. At this stage, the contact pressure, current density, node tempera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com