Method for quickly measuring thickness of metal coating

A metal coating, rapid measurement technology, applied in measuring devices, instruments, etc., can solve the problems of high requirements for laser pulse energy stability, laser beam focusing, difficulty in accurately determining the boundary between coating and substrate, and inability to distinguish between coating and substrate. Achieve the effect of non-destructive rapid detection, accurate and reliable detection results, and consistent ablation per unit pulse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

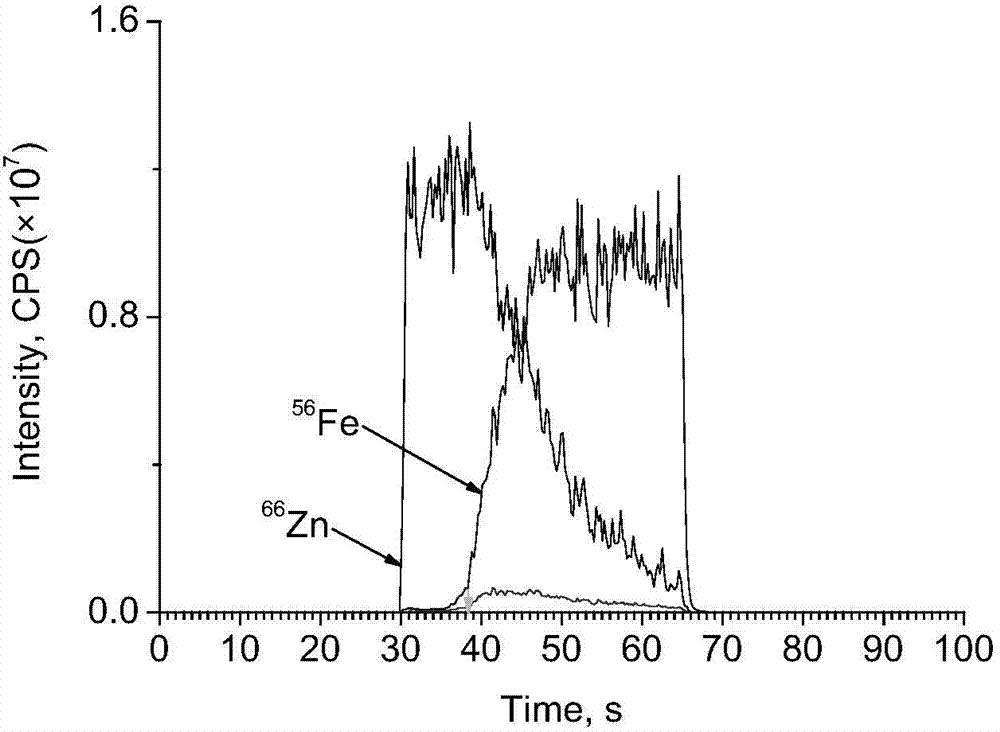

[0027] Embodiment one: a kind of method for measuring the thickness of metal coating rapidly, comprises the following steps:

[0028] ① Clean the surface of the sample with analytical pure anhydrous ethanol and air-dry it. The sample is No. 1 hot-dip galvanized steel sheet;

[0029] ② Place the sample in an argon atmosphere with a purity of 99.996%, and use a pulsed laser to ablate the sample in single-point ablation mode. The laser wavelength is 266nm, the pulse width is 30ps, the pulse frequency is 20Hz, and the laser pulse energy is 10μJ. The aperture diameter is 4mm, the defocus distance is 875μm, and the working mode of the pulse laser is fixed pulse working mode;

[0030] ③The ablated sample material is input into the inductively coupled plasma mass spectrometer along with the argon gas for analysis, and the inductively coupled plasma mass spectrometer collects data in the time-resolved analysis mode (TRA) in the peak jump mode to obtain the elements contained in the sam...

Embodiment 2

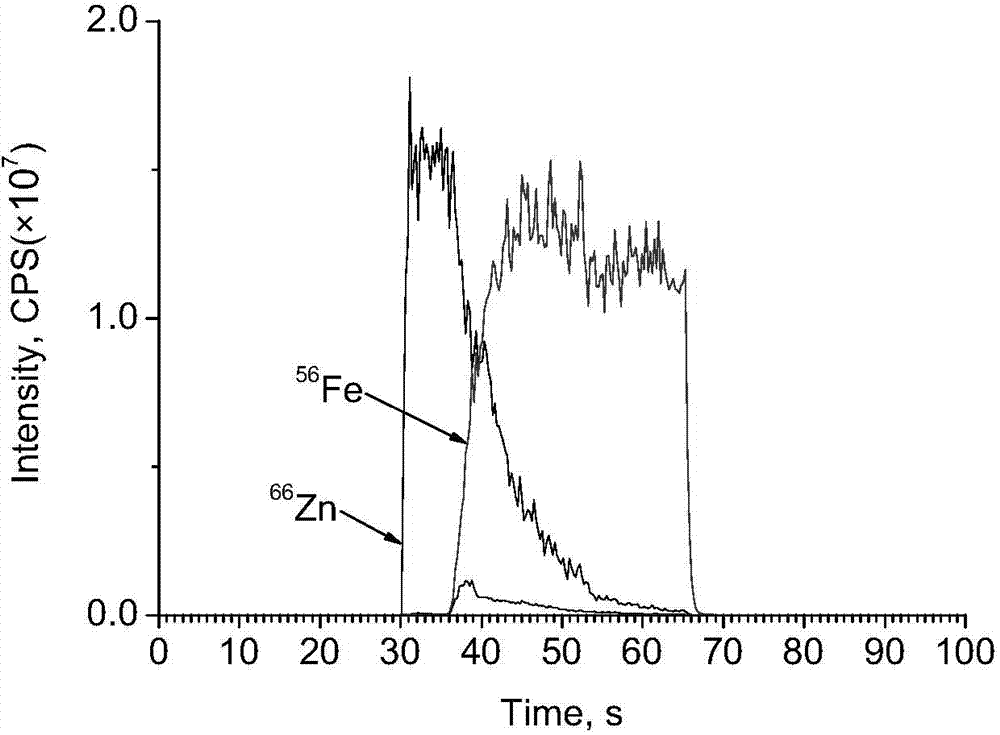

[0037] Embodiment two: a kind of method for measuring the thickness of metal coating rapidly, comprises the following steps:

[0038] ① Clean the surface of the sample with analytical pure anhydrous ethanol and air-dry it. The sample is No. 2 hot-dip galvanized steel sheet;

[0039] ② Place the sample in an argon atmosphere with a purity of 99.996%, and use a pulsed laser to ablate the sample in single-point ablation mode. The laser wavelength is 266nm, the pulse width is 30ps, the pulse frequency is 20Hz, and the laser pulse energy is 10μJ. The aperture diameter is 4mm, the defocus distance is 875μm, and the working mode of the pulse laser is fixed pulse working mode;

[0040] ③The ablated sample material is input into the inductively coupled plasma mass spectrometer along with the argon gas for analysis, and the inductively coupled plasma mass spectrometer collects data in the time-resolved analysis mode (TRA) in the peak jump mode to obtain the elements contained in the sam...

Embodiment 3

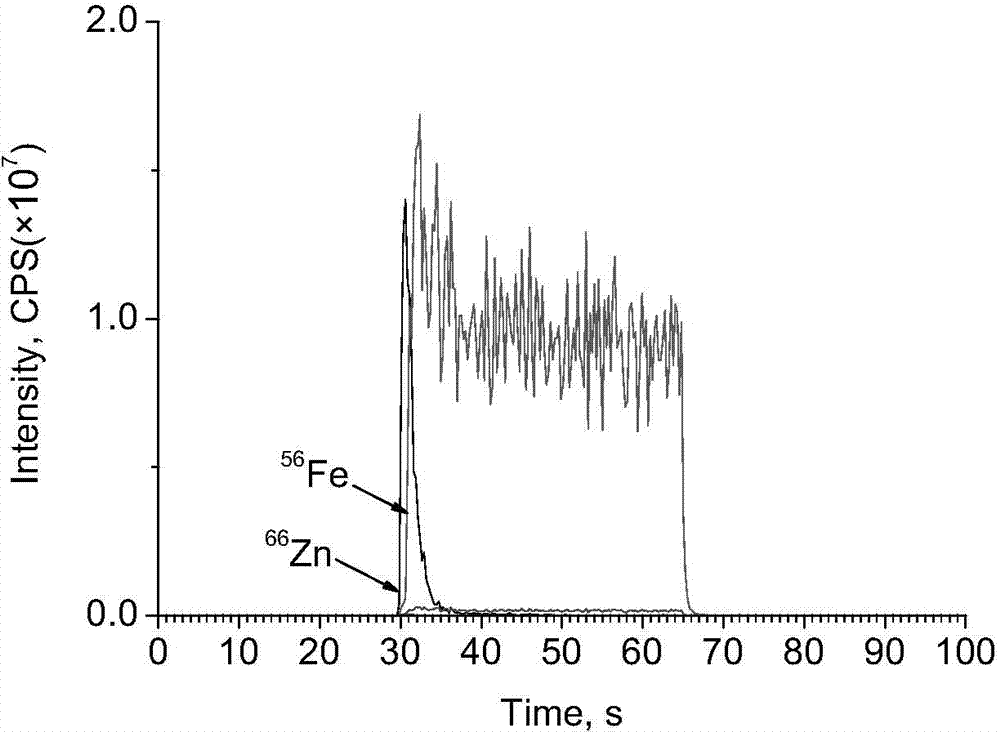

[0047] Embodiment three: a kind of method for measuring the thickness of metal coating rapidly, comprises the following steps:

[0048] ① Clean the surface of the sample with analytical pure ethanol and air-dry it. The sample is a white zinc nut;

[0049] ② Place the sample in an argon atmosphere with a purity of 99.996%, and use a pulsed laser to ablate the sample in single-point ablation mode. The laser wavelength is 266nm, the pulse width is 30ps, the pulse frequency is 20Hz, and the laser pulse energy is 10μJ. The aperture diameter is 4mm, the defocus distance is 875μm, and the working mode of the pulse laser is fixed pulse working mode;

[0050] ③The ablated sample material is input into the inductively coupled plasma mass spectrometer along with the argon gas for analysis, and the inductively coupled plasma mass spectrometer collects data in the time-resolved analysis mode (TRA) in the peak jump mode to obtain the elements contained in the sample material The time-resol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Laser wavelength | aaaaa | aaaaa |

| Pulse width | aaaaa | aaaaa |

| Pulse frequency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com