Glassy carbon electrode surface roughing preparation method based on ultra-short pulse laser micromachining

An ultra-short pulse laser and electrode surface technology, which is applied in laser welding equipment, metal processing equipment, welding equipment, etc., can solve the problems of high surface treatment quality and environmental protection requirements, and achieve fine processing, wide application prospects, and small thermal effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

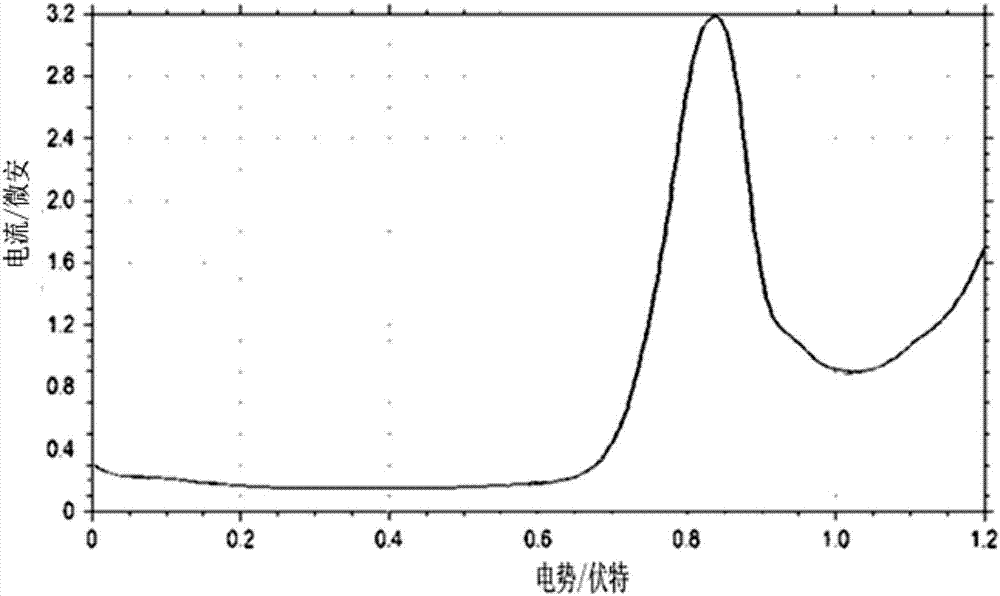

[0014] The surface of glassy carbon was roughened with different pulse width, pulse frequency, pulse power and processing time. The ultra-short pulse laser roughens the surface of the glassy carbon electrode, which will produce a micro-nano structure on the surface, greatly enhance the catalytic efficiency of the electrode, and greatly improve the signal-to-noise ratio.

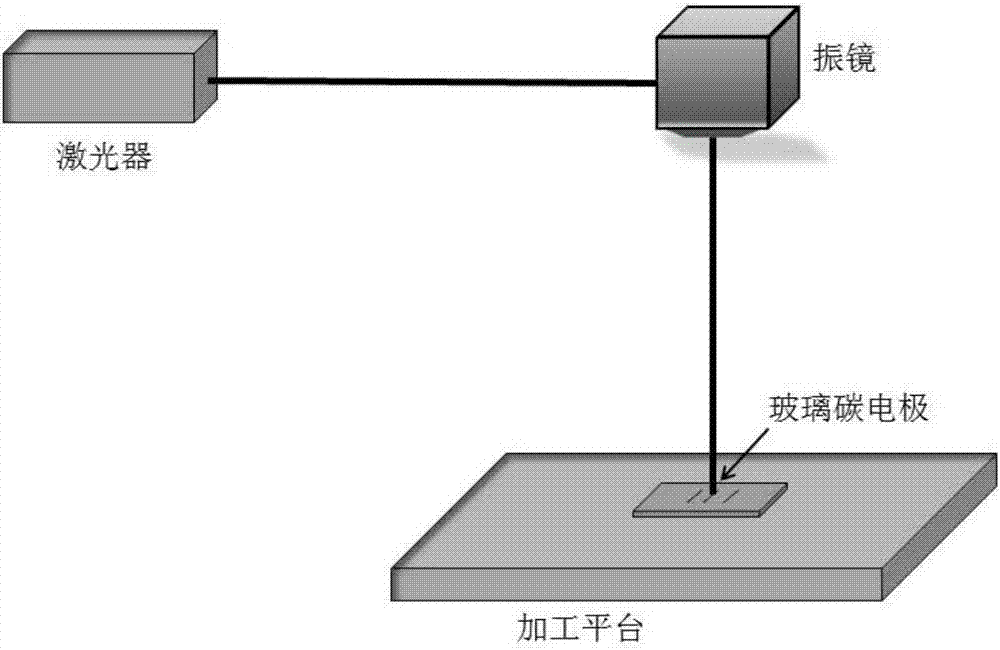

[0015] Such as figure 1 The schematic diagram of the device for processing glassy carbon electrodes is shown. The emitted light of the laser is aimed at the galvanometer, and the reflected light of the galvanometer is directly hit on the carbon glassy carbon electrode on the fixed processing platform. A tunable picosecond pulsed laser roughens glassy carbon electrodes. The specific surface roughening preparation method of the glassy carbon electrode is as follows:

[0016] 1. Before using the picosecond pulse laser to treat the glassy carbon electrode, first use 95% ethanol to ultrasonically clean the elect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com