Feedback type high-peak-power picosecond-pulse fiber laser system

A technology of fiber lasers and picosecond pulses, which is applied in the direction of lasers, laser components, phonon exciters, etc., can solve the problem of laser processing process consistency, integrity can not meet the requirements, affect the stability of laser output power, limit laser Peak power and other issues to achieve the effect of improving operational safety and flexibility, improving operability and safety, and improving waveforms

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Further description below in conjunction with accompanying drawings.

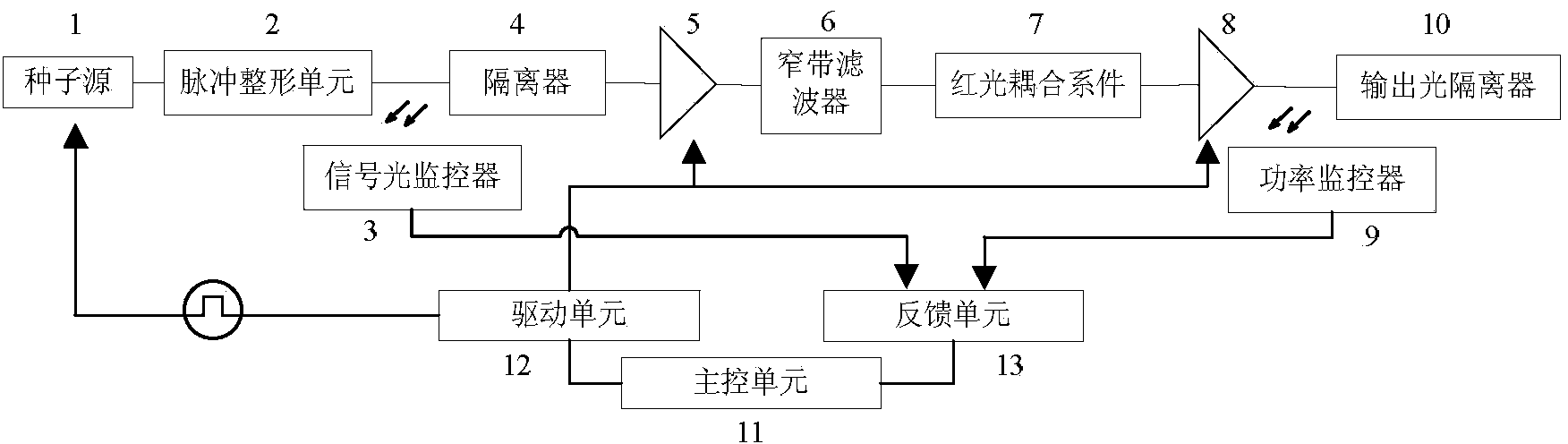

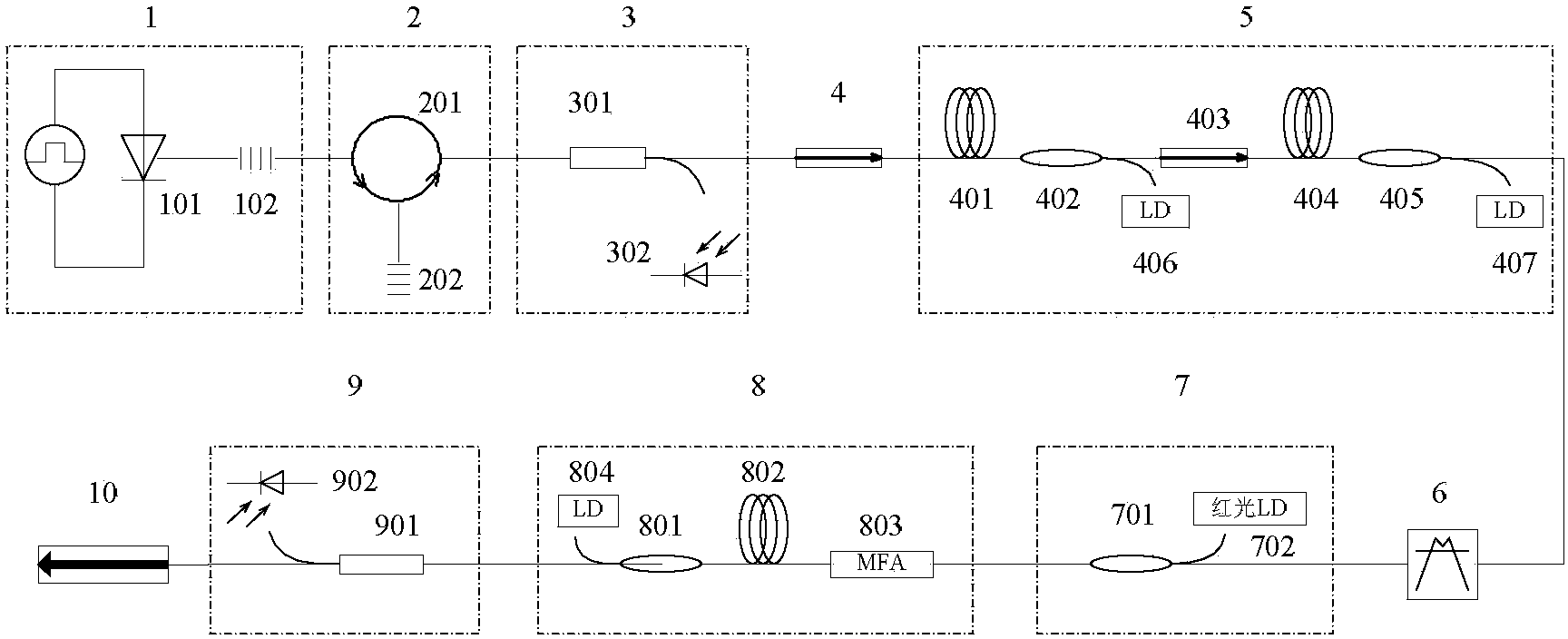

[0027] see figure 1 , the present invention consists of a seed source 1, a pulse shaping unit 2, a signal light monitor 3, an isolator 4, a pre-amplification stage 5, a narrowband filter 6, a red light coupler 7, a main amplifier stage 8, a power monitor 9, an output Optical isolator 10, main control unit 11, drive unit 12, feedback unit 13 constitute; It is characterized in that: main control unit 11 is connected with drive unit 12 and feedback unit 13 respectively, and drive unit 12 controls seed source 1, pre-amplification stage respectively 5. The main amplification stage 8; the driving unit 12 drives the seed source 1 to output picosecond-level seed light; after the seed light passes through the pulse shaping unit 2, a small part of the light reaches the signal light monitor 3, and most of the light passes through the isolator 4 It is injected into the pre-amplification stage 5, and then passes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com