STED (stimulated emission depletion)-based device and method for measuring smooth free-form surface sample

A sample, free technology, applied in measurement devices, optical devices, instruments, etc., can solve problems such as no industrial samples, inability to overcome the extremely weak light intensity of collected signals, etc., to achieve the effect of super-resolution imaging and high-precision measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0029] This embodiment is an embodiment of a device and a method.

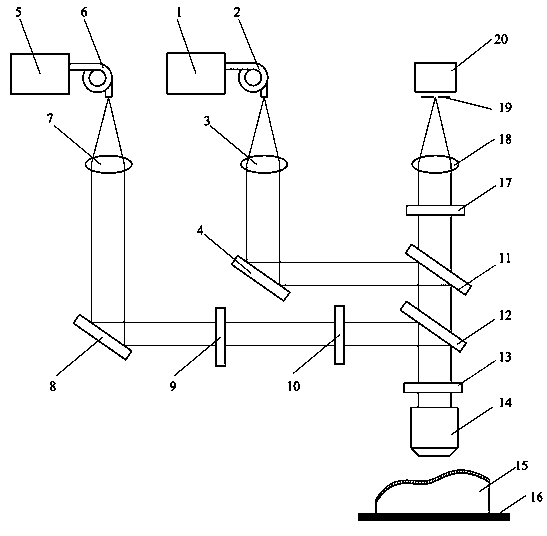

[0030] According to the method of measuring the smooth free-form surface sample device based on STED in this embodiment, the structural diagram is as follows figure 1 shown. The device includes: an excitation module, a loss module, a scanning imaging module and a coating sample 15;

[0031] The excitation module includes: a wavelength of λ 1 The first picosecond pulse laser 1, the first guide fiber 2, the first collimating objective lens 3 and the first plane mirror 4; at a wavelength of λ 1 After the first picosecond pulsed laser 1, the first guide fiber 2, the first collimating objective lens 3 and the first plane mirror 4 are sequentially configured;

[0032] The loss module includes: the wavelength is λ 2 The second picosecond pulse laser 5, the second guide fiber 6, the secon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com