Pretreatment method and system for material surface before laser welding

A pretreatment, laser welding technology, applied in laser welding equipment, welding equipment, metal processing equipment and other directions, can solve the problems of low laser reflectivity, laser absorption rate, single material processing, affecting laser welding efficiency, etc., to achieve good heat dissipation , Improve the absorption efficiency, the effect of fast transition time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

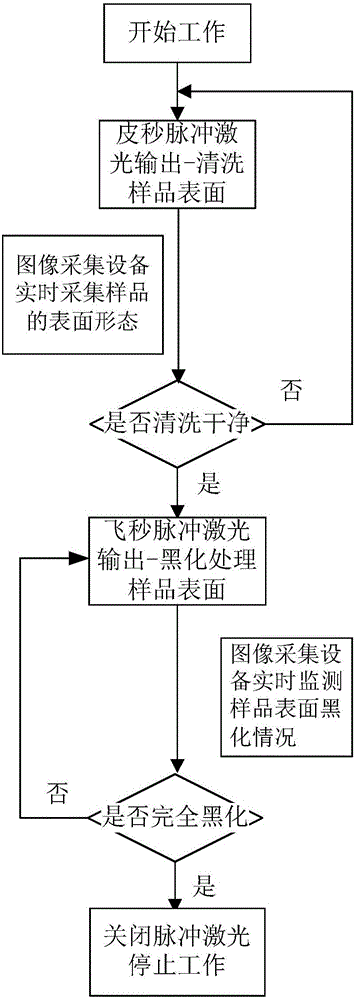

[0037] figure 1 Shown, a kind of specific embodiment of the method of the present invention is: a kind of pretreatment method of material surface before laser welding, comprises at first cleaning material sample surface by picosecond pulse laser, it is characterized in that: after passing picosecond pulse laser While cleaning the surface of the sample, the image acquisition equipment collects the surface morphology of the sample in real time, and judges whether the surface of the sample is cleaned according to the surface morphology of the sample: if it is not cleaned, continue to clean the surface of the sample with picosecond pulse laser; if it is cleaned , turn off the picosecond pulse laser, and blacken the surface of the sample through the femtosecond laser; while blackening the surface of the sample through the femtosecond laser, the image acquisition equipment monitors the blackening of the sample surface in real time. After blackening, turn off the femtosecond laser to...

Embodiment 2

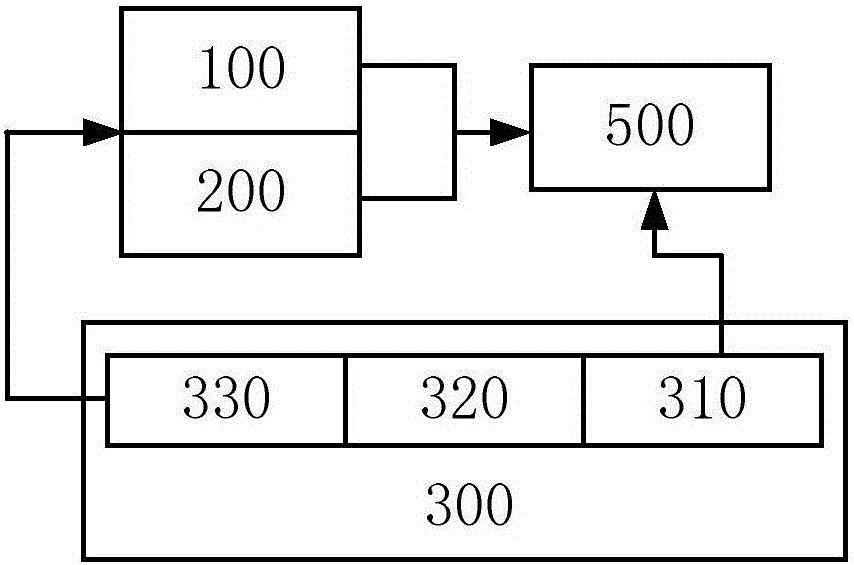

[0041] figure 2 It is shown that a specific embodiment of the system of the present invention is: a pretreatment system for the surface of materials before laser welding, including a laser processing module, characterized in that: the laser processing module includes laser cleaning for cleaning the surface of the sample 500 The submodule 100 and the laser blackening submodule 200 that blackens the surface of the sample 500; the switching between the laser cleaning submodule 100 and the laser blackening submodule 200 is controlled by the intelligent control module 300, and the intelligent control module 300 includes image acquisition Submodule 310, intelligent judgment submodule 320 and control submodule 330; the image acquisition submodule 310 is used to collect the surface morphology of the sample 500 and is transmitted to the intelligent judgment submodule 320; the intelligent judgment submodule 320 is used for according to the sample 500 The surface morphology judges wheth...

Embodiment 3

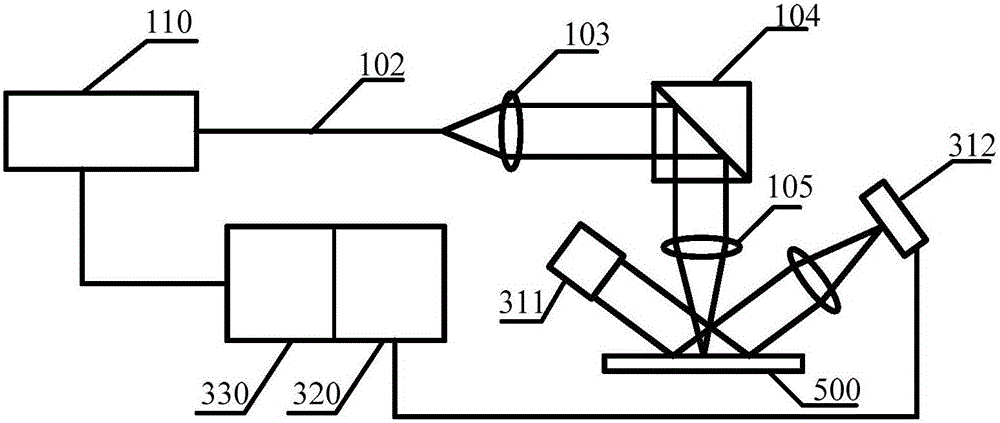

[0047] Figure 5 As shown, another specific embodiment of the system of the present invention is: a pretreatment system for the surface of materials before laser welding, including a laser processing module, characterized in that: the laser processing module includes a laser for cleaning the surface of the sample 500 The cleaning sub-module 100 and the laser blackening sub-module 200 for blackening the surface of the sample 500; the switching between the laser cleaning sub-module 100 and the laser blackening sub-module 200 is controlled by an intelligent control module 300, and the intelligent control module 300 includes an image Collection sub-module 310, intelligent judgment sub-module 320 and control sub-module 330; the image collection sub-module 310 is used to collect the surface morphology of the sample 500 and is transmitted to the intelligent judgment sub-module 320; 500 surface morphology judges whether the surface of the sample 500 is cleaned; the control submodule 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com